You've seen it happen. The prototype for your new ventilator or fluid delivery system passes every initial mechanical test with flying colors. The flexible bellow compresses and expands perfectly. But then, weeks into reliability testing—or worse, after the first few sterilization cycles—things go wrong. The once-pliable component has become stiff and brittle, or it's developed a strange, sticky residue. Your test data is now unreliable, your project timeline is in jeopardy, and you’re left chasing a phantom problem that seems to have no clear cause.

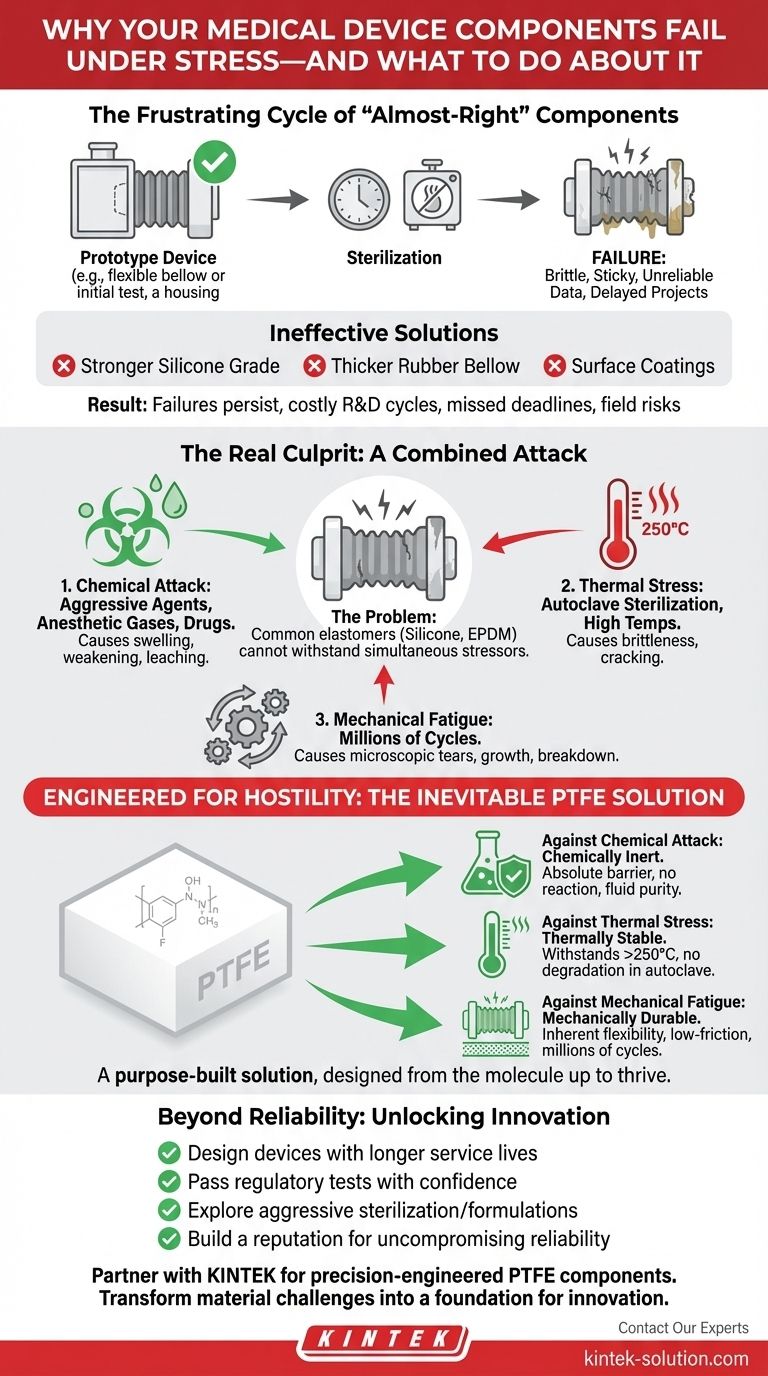

The Frustrating Cycle of 'Almost-Right' Components

This scenario is frustratingly common for medical device engineers. When a component designed for flexibility fails, the immediate response is often to treat it as a simple mechanical issue. The team might try:

- Switching to a "stronger" grade of medical silicone.

- Increasing the wall thickness of a rubber bellow.

- Applying a surface coating to improve durability.

These are logical steps, but they rarely solve the problem for good. The failures persist, leading to a cascade of negative business consequences: endless R&D cycles burn through budgets, critical project deadlines are missed, and the risk of a post-launch field failure looms, threatening both patient safety and your company's reputation. Each failed test isn't just a technical setback; it's a costly delay that pushes your innovation further from the market.

The Real Culprit: It's Not a Single Weakness, It's a Combined Attack

Here is the turning point in understanding this problem: The component is not failing because it lacks mechanical strength. It's failing because it cannot withstand the simultaneous chemical, thermal, and mechanical stresses of its operating environment.

Most common elastomers, like silicone or EPDM rubber, are designed to handle one or two of these stressors well. But in a real-world medical device, they face a multi-front attack:

- Chemical Attack: Aggressive cleaning agents, potent anesthetic gases, and various drug formulations are not neutral. Over time, they can subtly seep into the material structure of elastomers, causing them to swell, weaken, or leach harmful substances.

- Thermal Stress: The high temperatures of an autoclave or other sterilization methods can fundamentally alter the properties of these materials, making them brittle and prone to cracking.

- Mechanical Fatigue: Millions of cycles of compression and expansion create microscopic tears that grow over time, especially when the material has already been weakened by chemical and thermal exposure.

The "stronger" silicone failed because while it might have handled the flexing, it couldn't handle the chemical exposure. The thicker rubber part failed because the heat from sterilization compromised its integrity. The common "solutions" fail because they only address one symptom while ignoring the root cause: the material itself was never suited for this complex, hostile environment.

Engineered for Hostility: The Inevitable PTFE Solution

To truly solve this problem, you don't need a tougher version of the wrong material. You need a material that is fundamentally indifferent to this environment—one that performs reliably because it is immune to the attacks that cause others to fail.

This is where Polytetrafluoroethylene (PTFE) becomes the logical, engineered solution. Its properties don't just offer an incremental improvement; they directly neutralize the root causes of failure:

- Against Chemical Attack: PTFE is one of the most chemically inert substances known. It simply does not react with aggressive solvents, gases, or pharmaceuticals. It provides an absolute barrier, ensuring both material integrity and fluid purity.

- Against Thermal Stress: With a service temperature range typically exceeding 250°C (482°F), PTFE remains completely stable during autoclave sterilization. It will not become brittle, soften, or degrade.

- Against Mechanical Fatigue: The inherent flexibility and low-friction surface of PTFE allow it to endure millions of cycles without material breakdown, ensuring consistent, long-term performance.

A component made from PTFE isn’t just a part; it's a purpose-built solution. It is a product of deep material science, designed from the molecule up to thrive in environments where other materials inevitably degrade.

Beyond Reliability: What's Possible When Your Components Simply Work

When you stop fighting with unreliable components, your entire innovation process is unlocked. Instead of spending resources on diagnosing recurring material failures, your team can focus on what truly matters: enhancing device performance, developing new features, and accelerating your time-to-market.

With the stability of precision-engineered PTFE components, you can:

- Design devices with longer service lives and lower maintenance requirements, creating a powerful competitive advantage.

- Pass regulatory material compatibility tests with confidence, smoothing your path to market approval.

- Explore more aggressive sterilization protocols or use more potent drug formulations without worrying about material degradation.

- Build a reputation for uncompromising reliability, which is the ultimate currency in the medical device industry.

The right material choice moves component selection from a source of risk to a foundation for innovation.

At KINTEK, we specialize in manufacturing precision PTFE components that provide this exact foundation of reliability for the world's leading medical, semiconductor, and laboratory companies. We understand that in your field, there is no margin for error. That’s why we partner with engineering teams to move beyond "almost-right" solutions and deliver components engineered for certainty. If you're facing a persistent material challenge, let's talk about how the fundamental properties of PTFE can be tailored to solve it for good. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work