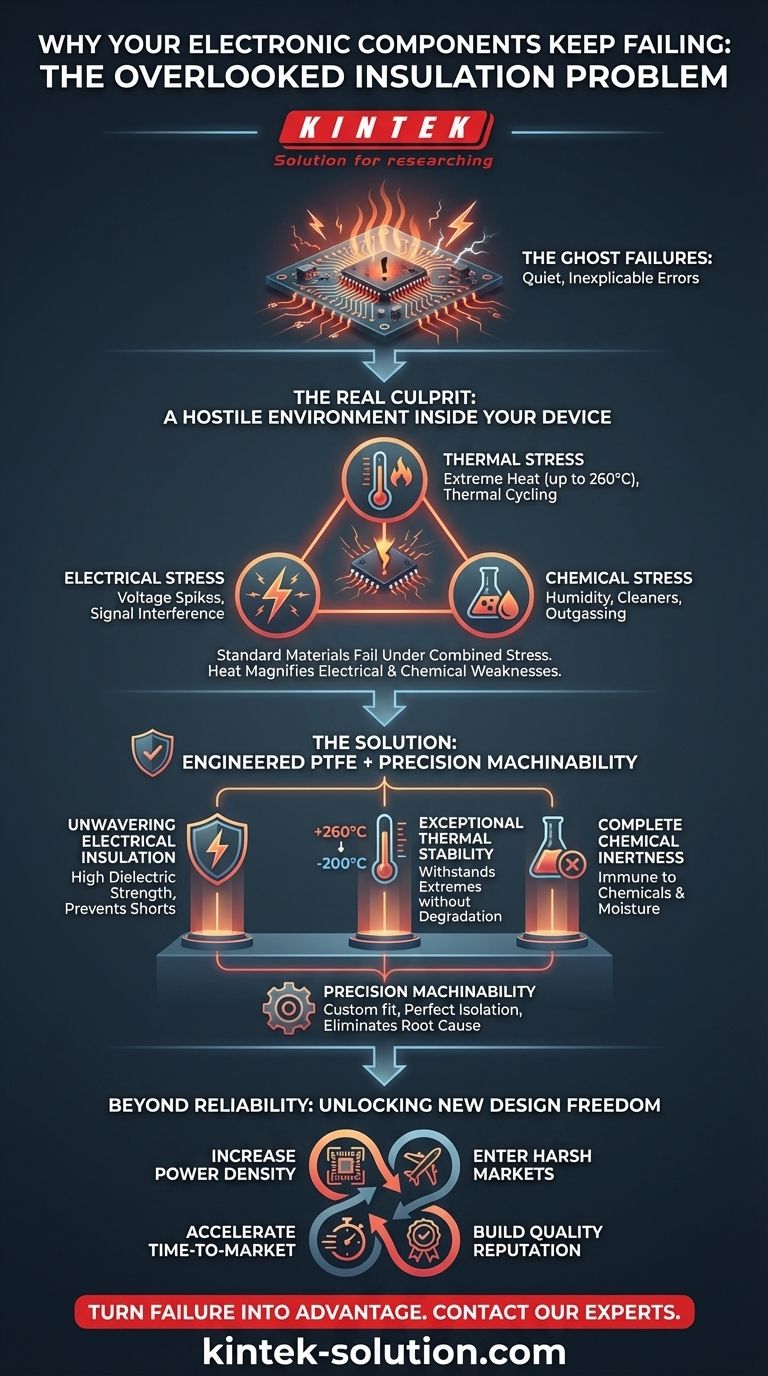

It’s a scenario every design engineer dreads. The prototype, after weeks of painstaking work, passes every initial test. It seems perfect. Then, a week into durability testing, it fails. Not with a dramatic spark, but a quiet, inexplicable error. Signal integrity degrades, a processor overheats, or a sensor gives erratic readings. You’re left staring at a device that should work, but doesn't, with no obvious cause.

The Endless Cycle of Troubleshooting

This isn't an isolated incident; it's a chronic headache in high-performance electronics design. When these "ghost" failures appear, the troubleshooting checklist begins.

You might blame a faulty solder joint, a noisy power supply, or even a bug in the firmware. The team might spend days, even weeks, swapping out active components, rerouting traces on the PCB, and adding more aggressive thermal management like fans or heatsinks.

Often, suspicion falls on the plastic insulators, spacers, or gaskets. "Maybe this off-the-shelf nylon spacer is the problem," someone suggests. So you swap it for another standard polymer. The problem seems to disappear, only to resurface in a different prototype under slightly different conditions.

This cycle of trial-and-error does more than just frustrate your engineering team. It creates very real business consequences:

- Project Delays: Each troubleshooting loop pushes your launch date further back.

- Budget Overruns: Time spent debugging is time not spent on new development, and a series of "quick fixes" adds up.

- Reputation Risk: If these intermittent faults make it into a final product, the cost of recalls and damage to your brand's reputation for reliability can be immense.

The core issue is that these common "solutions" are just shots in the dark because they fail to address the real, underlying cause of the failure.

The Real Culprit: A Hostile Environment Inside Your Device

The problem isn't one single factor. It's that the inside of a modern electronic device is a profoundly hostile environment, where multiple forces work together to degrade components. The true culprit is the destructive combination of electrical, thermal, and chemical stress.

Think of it like this:

- Electrical Stress: Your insulator’s primary job is to prevent current from going where it shouldn’t.

- Thermal Stress: High-performance processors, power regulators, and other components generate significant heat, baking everything around them.

- Chemical Stress: Over time, components are exposed to humidity, cleaning agents from the manufacturing process, or even outgassing from other materials inside the enclosure.

Most standard insulating materials are only good at handling one of these stresses at a time. A common plastic might be a great electrical insulator at room temperature, but once it gets hot, its molecular structure changes and its insulating properties plummet. Another material might withstand heat perfectly, but become brittle and crack after long-term exposure to trace chemicals.

Your components aren’t failing because of heat or voltage. They are failing because the heat is magnifying the electrical and chemical weaknesses of the materials you're using. The "fixes" you tried—like adding a heatsink or swapping to another standard plastic—were doomed to fail because they only addressed one piece of this three-part problem.

A Material Engineered for Hostility

To permanently solve a problem caused by multiple, simultaneous stresses, you need a material that can stand up to all of them at once. It needs to be a triathlete, not just a marathon runner.

This is precisely where Polytetrafluoroethylene (PTFE), commonly known as Teflon, excels. To truly solve the root cause, you need a solution that offers:

- Unwavering Electrical Insulation: PTFE has an extremely high dielectric strength that doesn’t falter, even as temperatures rise. It reliably prevents short circuits and signal interference.

- Exceptional Thermal Stability: It can withstand extreme temperatures (from cryogenic lows up to 260°C / 500°F) without melting, degrading, or losing its insulating properties.

- Complete Chemical Inertness: PTFE is virtually immune to all chemicals, moisture, and solvents, ensuring it will not corrode, weaken, or become contaminated over the entire lifespan of your product.

However, the material alone is only half the solution. In the compact, complex architecture of modern electronics, an off-the-shelf part rarely fits perfectly. A gap of a fraction of a millimeter can compromise an entire design.

This is why precision machinability is the fourth critical element. At KINTEK, we don't just supply PTFE; we fabricate custom components to your exact specifications. By machining PTFE into bespoke insulators, gaskets, and spacers, we ensure a perfect fit that completely isolates your sensitive components from the hostile environment surrounding them. Our solution is not just a better material; it's a precisely engineered barrier designed to eliminate the root cause of failure.

Beyond Reliability: Unlocking New Design Freedom

When you stop chasing ghosts and solve the component reliability problem at its source, something transformative happens. You don't just get a more reliable product; you gain the freedom to innovate.

With the confidence that your foundational components will perform under any condition, you can:

- Increase Power Density: Pack components closer together without fearing thermal or electrical crosstalk, leading to smaller, more powerful devices.

- Enter Harsh Markets: Confidently design products for demanding applications in aerospace, medical, and industrial sectors where failure is not an option.

- Accelerate Your Time-to-Market: Eliminate the unpredictable troubleshooting phase and move from design to production faster and more predictably.

- Build a Reputation for Quality: Deliver products that customers trust to work, every time, for years to come.

Your challenge isn't just to fix a failing prototype; it's to build a resilient platform for future innovation. By addressing the true environmental hazards inside your device with the right material and precision engineering, you can turn your biggest point of failure into your greatest competitive advantage. If you're ready to stop troubleshooting and start building more robust, reliable, and ambitious products, our team of specialists is here to help you engineer the perfect solution for your unique application. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- When 'Chemically Inert' Isn't Enough: Why Your PTFE Components Fail and How to Prevent It

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Asymmetric Cost of Failure: Why Precision PTFE Is Your Last Line of Defense

- The Engineer's Dilemma: Navigating the Trade-offs Between PTFE and Its Alternatives