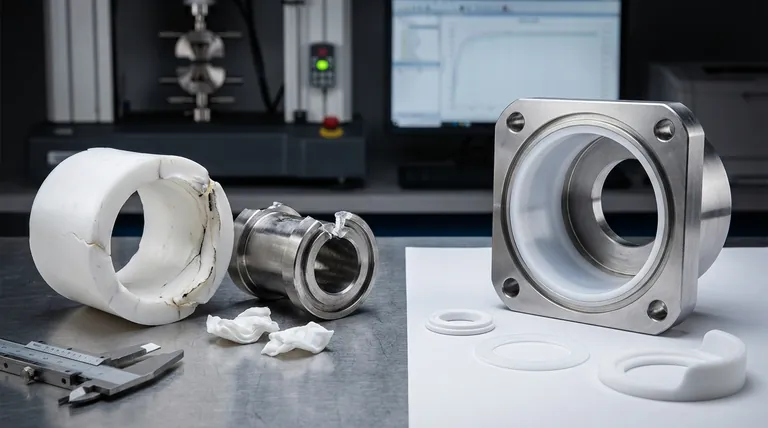

You’ve been here before. The design for the new high-performance pivot is perfect on paper. To make it impossibly smooth and maintenance-free, your team decided to use the best material they could think of: PTFE. You machine a beautiful, solid PTFE bushing, assemble the prototype, and it feels like glass.

Then, you put it on the test rig. Under real-world load, the "miracle" material deforms. The joint develops slop. Within hours, the component fails completely. The team is back to square one, staring at a piece of failed plastic, wondering why a material famous for performance just cost them weeks of work and thousands of dollars in R&D.

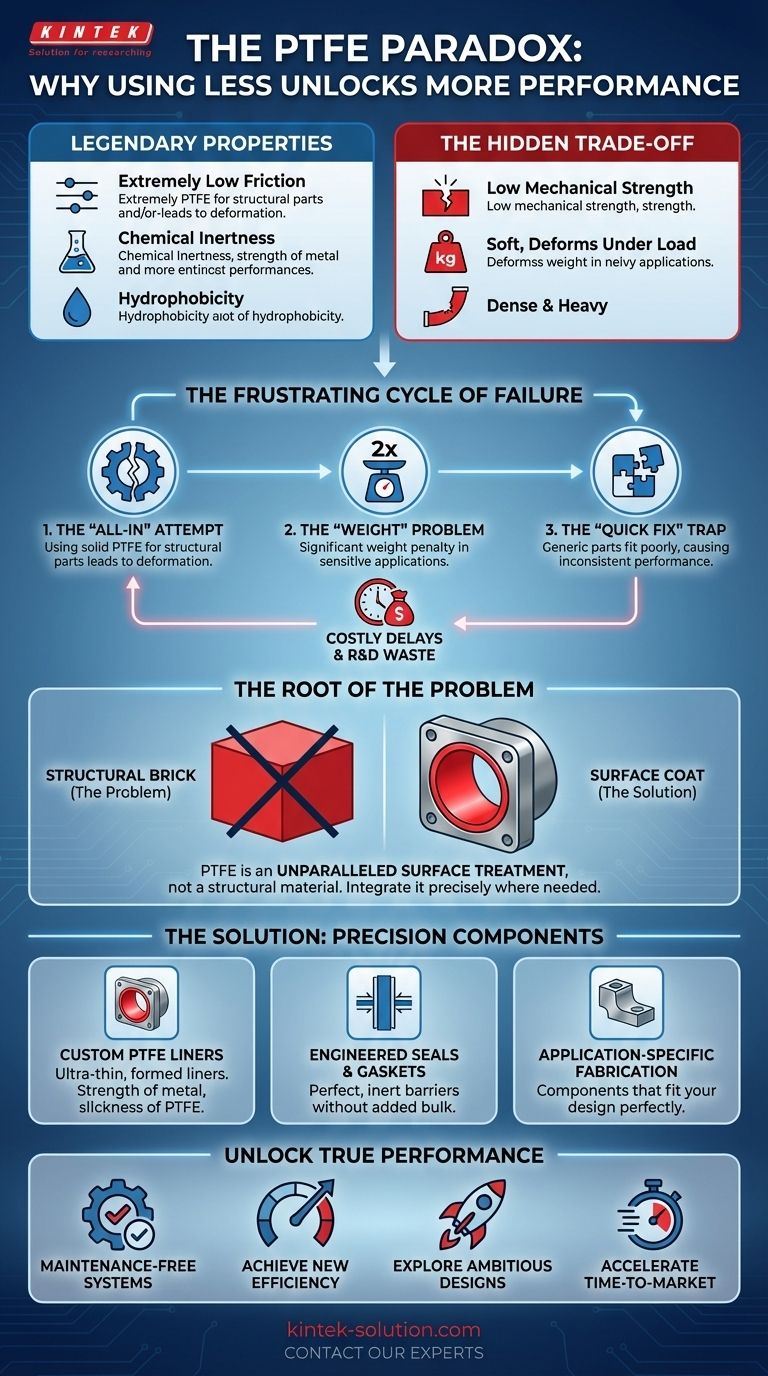

The Frustrating Cycle of "Performance" Material Failures

This scenario is far more common than most engineering teams would like to admit. The promise of PTFE (Polytetrafluoroethylene), often known by the brand name Teflon®, is legendary: an almost impossibly low-friction, chemically inert surface. This leads to a logical, yet flawed, conclusion: "If we want a high-performance part, let's build it out of this high-performance material."

This thinking kicks off a predictable and costly cycle:

- The "All-In" Attempt: Teams try to fabricate entire load-bearing components from solid PTFE, only to see them fail due to its inherent softness and poor mechanical strength.

- The "Weight" Problem: In designs where PTFE doesn't fail structurally, another issue appears. For a performance plastic, PTFE is surprisingly dense—roughly twice as heavy as common polymers like polypropylene. In weight-sensitive applications like aerospace or competitive sports, this is a significant penalty.

- The "Quick Fix" Trap: Teams then resort to off-the-shelf PTFE washers or sheets, hoping they'll solve the problem. But these generic parts rarely fit the precise geometric and load requirements of a custom design, leading to inconsistent performance and premature wear.

The business consequences are stark. Project timelines stretch as teams chase solutions. R&D budgets are consumed by failed prototypes and material waste. Worse, a product might even launch with a compromised design, leading to warranty claims, reputational damage, and a loss of market trust. You're left with a nagging question: how do competitors make it work?

The Root of the Problem: Is PTFE a Brick or a Coat of Paint?

The breakthrough comes when you stop thinking of PTFE as a structural building material (a brick) and start seeing it for what it truly is: an unparalleled surface treatment (a coat of paint).

The science is clear. PTFE’s value comes from its unique molecular structure, which gives it three elite properties:

- Extremely Low Friction: It’s one of the slipperiest solids known to science.

- Chemical Inertness: It resists almost all chemicals, oils, and solvents.

- Hydrophobicity: It repels water and prevents things from sticking to it.

However, these surface properties come with a critical trade-off: PTFE has very low mechanical strength and rigidity. It's soft and cannot bear significant structural loads on its own.

This is why the common "solutions" fail. Building a structural part from solid PTFE is like trying to build a house wall out of paint. It's using the material for a purpose it was never designed for. The material itself isn't the problem; the application is. The secret isn't to build with PTFE, but to design a strong structural part (made from metal or a tougher polymer) and then integrate PTFE only at the critical surface where you need its unique properties.

The Solution Embodied: Precision Components for a Precision Job

To truly solve this problem, you need to stop forcing a square peg into a round hole. You need a way to apply PTFE's slick, durable surface precisely where it's needed, without compromising the mechanical integrity of your overall assembly.

This is where the right tool comes in. The solution isn’t raw PTFE material; it's a precisely manufactured PTFE component—a liner, a seal, or a custom-fit insert—designed to work in harmony with a stronger host part.

This is the core of what we do at KINTEK. We don’t just sell PTFE; we engineer solutions based on a deep understanding of the material’s strengths and weaknesses. Our products are the embodiment of the correct approach:

- Custom PTFE Liners: Our ultra-thin, precision-formed liners can be integrated into a robust metal housing. You get the strength of the metal and the unparalleled slickness of the PTFE surface, solving the friction problem without any structural compromise.

- Engineered Seals and Gaskets: We fabricate PTFE seals that provide a perfect, chemically inert barrier exactly where you need it, protecting sensitive internal components from degradation without adding unnecessary weight or bulk.

- Application-Specific Fabrication: Instead of you trying to machine a difficult material, our expertise in precision production delivers a component that fits your design perfectly, from a single prototype to high-volume orders.

Our components aren't just accessories; they are the key that unlocks PTFE's true potential by applying it intelligently, directly targeting the root cause of the friction and durability problem.

Beyond the Fix: What Will You Build Now?

Once you stop fighting with PTFE and start using it strategically, new possibilities open up. The energy once spent on fixing failed prototypes can now be channeled into genuine innovation.

With this persistent engineering headache solved, you can now:

- Design maintenance-free systems that operate smoothly for years, not months, boosting customer satisfaction and reducing warranty costs.

- Achieve new levels of efficiency in equipment where even small amounts of friction were holding back performance.

- Explore more ambitious designs in harsh chemical or high-temperature environments, knowing your critical surfaces are protected.

- Accelerate your time-to-market by starting with an engineered solution that works, rather than a cycle of trial and error.

The goal isn't just to fix a single failing component. It's about removing a fundamental barrier to performance and reliability across your entire product line. When you have a reliable way to solve friction and wear, what new challenges will you take on?

If you're ready to move past the cycle of frustration and unlock the true performance of your designs, our team is here to help. We specialize in turning complex material challenges into reliable, precision-engineered solutions. Let's discuss your project's unique demands and how the strategic use of PTFE components can help you achieve your goals. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure