The Invisible War in Every Machine

Imagine a single bearing inside a semiconductor fabrication robot, performing millions of precise movements a day. Or a valve seal in a medical device, regulating flow with absolute reliability.

In each rotation, in every slide, an invisible war is waged against friction.

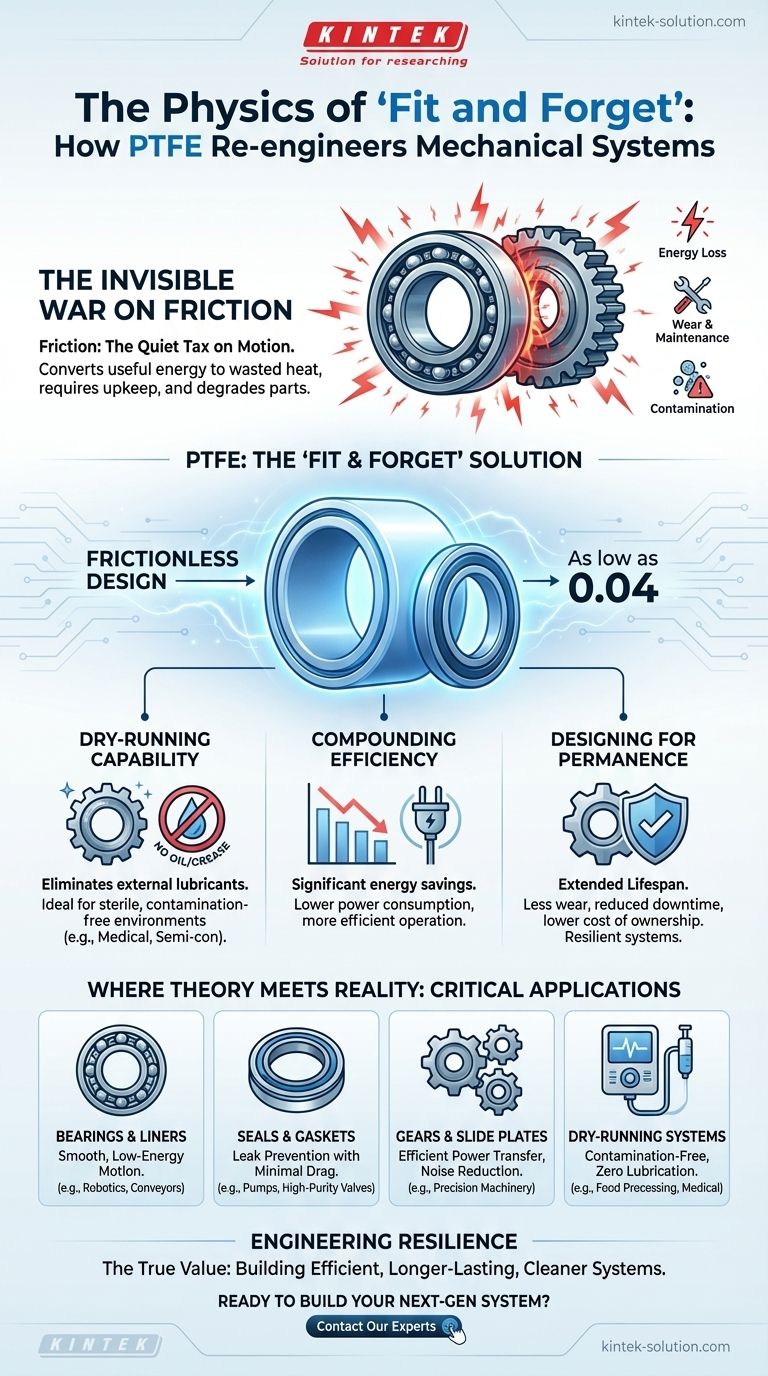

Friction is the quiet tax on all mechanical motion. It converts useful energy into wasted heat. It grinds down surfaces, mandating maintenance and eventual replacement. We've been taught to accept this as a fundamental cost of doing business with physics.

But what if we could design systems where this tax was nearly zero? This isn't just about making parts "slippery." It's about changing our entire approach to mechanical design.

Frictionless Design: A Shift in Mindset

The introduction of Polytetrafluoroethylene (PTFE) wasn't just the arrival of a new material. It was the introduction of a new engineering philosophy.

The goal is no longer to manage friction with messy lubricants and frequent upkeep, but to design it out of the system from the start. This creates components that are, in a sense, "fit and forget."

This shift is rooted in a few core principles that have compounding returns.

The Power of 'Dry-Running'

Traditional systems rely on oils and greases. These lubricants work, but they are a liability. They attract contaminants, require replenishment, and are strictly forbidden in sterile environments.

PTFE, with its inherent low friction, requires no external lubricant.

This "dry-running" capability is revolutionary. For industries like semiconductor manufacturing, medical devices, or laboratory analysis, it eliminates a primary source of contamination. It simplifies design and removes an entire category of maintenance tasks.

The Compounding Returns of Efficiency

Friction doesn't just cause wear; it bleeds energy. In a large industrial machine with hundreds of moving parts, this parasitic drag adds up to a significant operational cost.

By engineering with a material that has a coefficient of friction as low as 0.04, you are fundamentally lowering the energy floor of the system. Less force is required for every movement, leading directly to lower power consumption and more efficient operation, especially in continuous-motion applications.

Designing for Permanence, Not Replacement

Friction is a direct cause of physical degradation. Less friction means less wear. It's that simple.

When components like bushings, washers, and seals are made from PTFE, their operational lifespan increases dramatically. The calculus shifts from planning for replacement to designing for permanence. This reduces machine downtime, lowers the cost of ownership, and builds more resilient, reliable systems.

Where Theory Meets Reality

This philosophy is not abstract. It is applied daily in critical components where failure is not an option.

| Application | Core Benefit | Common Use Cases |

|---|---|---|

| Bearings & Liners | Smooth, low-energy motion | Conveyor rollers, automotive systems, robotics |

| Seals & Gaskets | Leak prevention with minimal drag | Hydraulic cylinders, pumps, high-purity valves |

| Gears & Slide Plates | Efficient power transfer, noise reduction | Precision machinery, laboratory equipment |

| Dry-Running Systems | Contamination-free, zero lubrication | Medical devices, semiconductor, food processing |

A Material of Intent: Understanding the Trade-offs

Of course, no material is a universal panacea. Engineering is a discipline of trade-offs.

PTFE has lower compressive strength than metals and is more susceptible to "creep" under sustained load. It also has a higher coefficient of thermal expansion, a critical factor in designs with tight tolerances that operate across a range of temperatures.

But these are not weaknesses; they are known variables.

This is where expert fabrication becomes critical. Often, the optimal solution is not a solid PTFE part, but a component that combines the strength of a metal substrate with the unparalleled low-friction surface of a precisely machined PTFE liner. This hybrid approach delivers the best of both worlds: structural integrity and frictionless performance.

The Goal is Resilient Systems, Not Slippery Parts

The true value of PTFE isn't its low coefficient of friction, but the systems it enables. It allows us to build machines that are more efficient, last longer, and run cleaner than ever before. It helps us move from a world of constant maintenance to one of engineered resilience.

Achieving this requires more than just choosing a material; it demands a partner who understands the physics, the trade-offs, and the precision required to turn a design philosophy into a physical reality. For custom PTFE components designed to solve the core challenges of friction, wear, and purity in your most critical applications, you need a specialist in precision fabrication.

To build your next-generation system, Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

Related Articles

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work