You’ve seen it before. A critical flange connection, meticulously assembled with a new gasket and torqued to spec, starts to weep. A small, persistent leak that defies logic. Your team tightens the bolts again. The leak might stop for a day, maybe a week, but it returns. You replace the gasket, maybe even with a more expensive, harder material, only to find yourself back at square one, fighting the same frustrating battle.

This isn't just an annoyance; it's a drain on your entire operation.

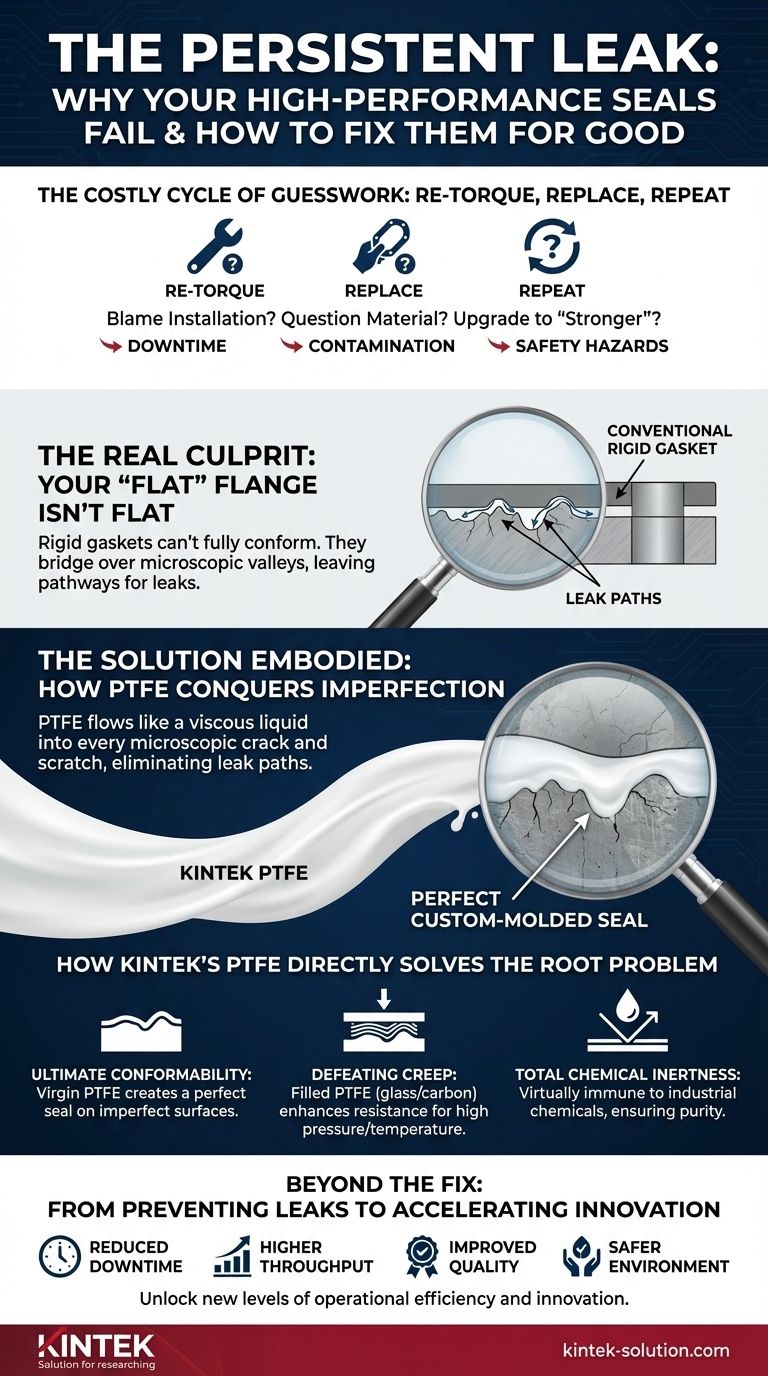

The Costly Cycle of Guesswork: Re-Torque, Replace, Repeat

For engineers and maintenance managers in demanding industries like semiconductor, medical, or chemical processing, this scenario is all too common. When a seal fails, the troubleshooting checklist usually looks something like this:

- Blame the installation: "Was it tightened correctly? Is the torque sequence right?"

- Question the material: "Maybe this gasket can't handle the chemical? Or the temperature?"

- Upgrade to a "stronger" gasket: The intuitive next step is often to choose a more rigid material, assuming hardness equals durability.

Each attempt is a shot in the dark, and the consequences are very real. Every hour of downtime for diagnostics and replacement is an hour of lost production. A single leak in a high-purity process can contaminate an entire batch, costing thousands. In aggressive chemical applications, it becomes a serious safety and environmental hazard. You're stuck in a reactive loop, treating symptoms without ever curing the disease.

The Real Culprit: Your "Flat" Flange Isn't Flat

Here is the turning point. The reason these conventional fixes fail is that they are based on a flawed assumption: that the problem is the gasket's strength or the installer's technique.

The real root cause is often the sealing surface itself.

No matter how well-machined, no industrial flange is perfectly flat. On a microscopic level, its surface is a landscape of tiny peaks, valleys, scratches, and waves. When you compress a rigid gasket—like metal or a hard polymer—between two of these imperfect surfaces, it can't fully conform. It bridges over the microscopic valleys, leaving minuscule pathways for leaks to begin.

This is why trying a "harder" gasket often makes the problem worse. It's like trying to seal a gap between two pieces of sandpaper by pressing another piece of wood between them. The rigidity prevents a true, intimate seal.

Furthermore, even if you achieve an initial seal, another hidden enemy comes into play: creep, or "cold flow." Under sustained pressure and temperature, some materials slowly deform and lose the "push back" force that keeps the seal tight. A gasket that worked on day one can fail on day thirty, not because of a sudden event, but due to this slow relaxation.

The Solution Embodied: How PTFE Conquers Imperfection

To solve this problem permanently, you don't need a harder material; you need a smarter one. You need a material engineered to address the physical reality of imperfect surfaces and long-term stress.

This is where Polytetrafluoroethylene (PTFE) demonstrates its genius.

Unlike rigid materials, PTFE is inherently soft and plastic. When compressed, it doesn't just resist the force; it flows like a viscous liquid into every microscopic crack, scratch, and valley on the flange face. It creates a perfect, custom-molded impression of the surface, eliminating the leak paths that rigid gaskets leave behind.

This is not a lucky accident; it's the core of why PTFE works where others fail. At KINTEK, we've built our reputation on mastering this principle. We don't just sell PTFE components; we engineer sealing solutions based on a deep understanding of this mechanism.

How KINTEK's PTFE Directly Solves the Root Problem:

- Ultimate Conformability: Our virgin PTFE seals provide unparalleled softness to create a perfect seal on even less-than-ideal surfaces, ensuring leak-free performance from the start.

- Defeating Creep: For applications with high pressure or temperature where creep is a concern, we utilize specialized filled PTFE (with glass or carbon) to dramatically enhance creep resistance and compressive strength, ensuring long-term seal integrity.

- Total Chemical Inertness: PTFE is virtually immune to all industrial chemicals. This means the seal will never swell, weaken, or leach contaminants into your process—a critical guarantee for semiconductor and medical purity.

Our precision manufacturing process ensures that every seal, liner, or custom component delivers these properties consistently, from a single prototype to a high-volume production run.

Beyond the Fix: From Preventing Leaks to Accelerating Innovation

Once you eliminate the chronic problem of unreliable seals, it fundamentally changes what’s possible for your operation.

You are no longer limited by the constant need for maintenance and monitoring. You can run high-temperature or cryogenic processes for longer durations with confidence. You can push the boundaries with more aggressive process chemicals, knowing your seals won't be the point of failure. For R&D labs, this means more reliable experimental data. For manufacturing lines, it means higher throughput, improved product quality, and a safer working environment.

Ultimately, solving the persistent leak isn't just about plugging a hole. It's about unlocking new levels of operational efficiency and innovation.

Stop the cycle of guesswork and start engineering a permanent solution. If you're facing a persistent sealing challenge that is costing you time and money, our team can help you identify the root cause and specify the precise PTFE solution to solve it for good. Let's discuss the unique demands of your project. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- The Unseen Component: How PTFE Became the Bedrock of Medical Device Reliability

- The Asymmetric Cost of Failure: Why Precision PTFE Is Your Last Line of Defense

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Engineer's Dilemma: Navigating the Trade-offs Between PTFE and Its Alternatives

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good