It’s a scene familiar to many engineers and lab technicians: a persistent, slow drip from a critical flange connection. You’ve checked the alignment. You’ve torqued the bolts to spec, maybe even a little more. You might have even replaced the PTFE gasket with a brand new one. Yet, a few days or thermal cycles later, the leak returns. This isn't just frustrating; in high-purity environments like semiconductor manufacturing or medical labs, it’s a costly and potentially catastrophic failure.

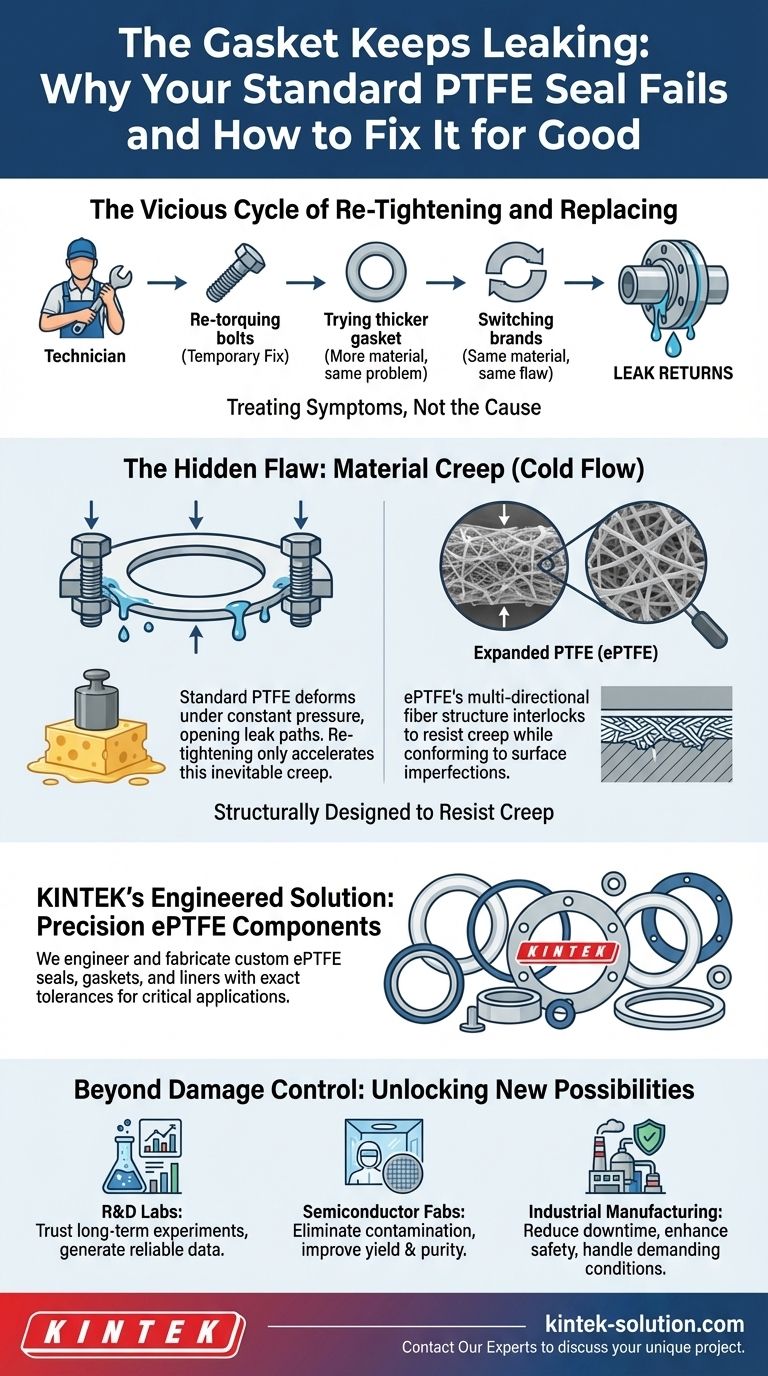

The Vicious Cycle of Re-Tightening and Replacing

When a seal fails, the immediate reaction is to find a fault in the installation. Did we tighten it enough? Is the flange surface damaged? These are valid questions, leading to a common cycle of troubleshooting:

- Re-torquing the bolts: You apply more force, hoping to compress the gasket further and close the leak path. This might offer a temporary fix.

- Trying a thicker gasket: The logic seems sound—more material should create a better seal.

- Blaming the brand: You switch to a different manufacturer of the same type of "high-performance" PTFE gasket, hoping for better quality.

While these efforts are logical, they often end in the same frustrating leak. That's because they are merely treating the symptoms. The real problem is far more fundamental.

These repeated failures have significant business consequences. In a semiconductor fab, a single leak can compromise an entire batch of high-purity chemicals, leading to wafer contamination and millions in lost product. In a pharmaceutical plant, it can mean production halts, extensive cleaning validation, and project delays that postpone a drug's time-to-market. The "simple" gasket failure quickly becomes a major operational and financial headache.

The Hidden Flaw: It's Not the Gasket, It's the Microstructure

The reason your standard PTFE gaskets keep failing isn't your wrench or your process. The problem is baked into the material's molecular structure.

Most people choose PTFE for its incredible chemical resistance. But standard, solid PTFE—whether it's pure "virgin" PTFE or "filled" PTFE with glass or silica—suffers from a critical weakness: creep, also known as "cold flow."

What is Creep?

Imagine placing a heavy book on a block of hard cheese. At first, it holds its shape. But if you leave it for a few days, you'll see the cheese has slowly flattened and oozed out from under the weight.

This is exactly what happens to a standard PTFE gasket under the constant pressure of flange bolts. The material slowly deforms and flows away from the point of compression. As the gasket thins out, the bolt pressure decreases, a leak path opens, and your seal fails.

This is why re-tightening only works temporarily; you are just accelerating the inevitable creep. It's why a thicker gasket doesn't help; you're just providing more material to flow away. These "solutions" don't address the root cause.

The Right Tool: Sealing with Structural Integrity

To permanently solve this problem, you don't need more force or more material. You need a material that is structurally designed to resist creep while still being conformable enough to seal imperfect surfaces.

This is where expanded PTFE (ePTFE) comes in.

Instead of a solid, dense block, ePTFE is created through a special process that stretches pure PTFE, creating a complex, multi-directional web of fibers. This fibrous, porous structure is the key.

When compressed, these fibers interlock and press against each other, creating a strong, stable matrix that refuses to flow or creep. At the same time, this soft structure is incredibly compressible, allowing it to flow into and perfectly seal every tiny scratch, pit, and imperfection on a flange surface—something solid gaskets struggle with.

This is not a happy accident; it's the result of deep material science. KINTEK manufactures precision components from ePTFE because it is the engineered answer to the fundamental flaws of standard PTFE. Our expertise lies not just in sourcing premium ePTFE, but in fabricating it into custom seals, gaskets, and liners with the exact dimensions and tolerances your critical application demands. Our components aren't just parts; they are solutions born from a deep understanding of why seals fail.

Beyond Damage Control: What Reliable Sealing Unlocks

When you stop worrying about leaks, a new world of possibilities opens up. The conversation shifts from reactive maintenance to proactive innovation.

- For R&D Labs: Instead of interrupting long-term experiments to chase down a leak, your team can trust the integrity of their setup for weeks or months, generating more reliable and consistent data.

- For Semiconductor Fabs: With the risk of chemical contamination from a leaky seal virtually eliminated, you can push for higher process purity, leading to improved wafer yields and more reliable chip performance.

- For Industrial Manufacturing: You can reduce scheduled maintenance downtime, improve plant safety by containing hazardous materials more effectively, and confidently run processes at more demanding temperatures or pressures.

Ultimately, solving the "creeping gasket" problem means your best minds are freed up to focus on what truly matters: optimizing your process, developing new products, and driving your business forward.

If you're tired of the endless cycle of chasing leaks, it's time to address the root cause. Whether you're battling persistent failures in a legacy system or designing a next-generation device that demands absolute sealing integrity, our team has the material science expertise and precision manufacturing capability to help. Contact Our Experts to discuss your unique project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

Related Articles

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics