It’s a scenario that plays out in labs and on production floors everywhere: a critical process grinds to a halt. After hours, or even days, of frantic troubleshooting, the culprit is found: a small, seemingly insignificant plastic component that has warped, cracked, or degraded. The batch is ruined, the timeline is shot, and a frustrating question hangs in the air: "Why did this part fail?"

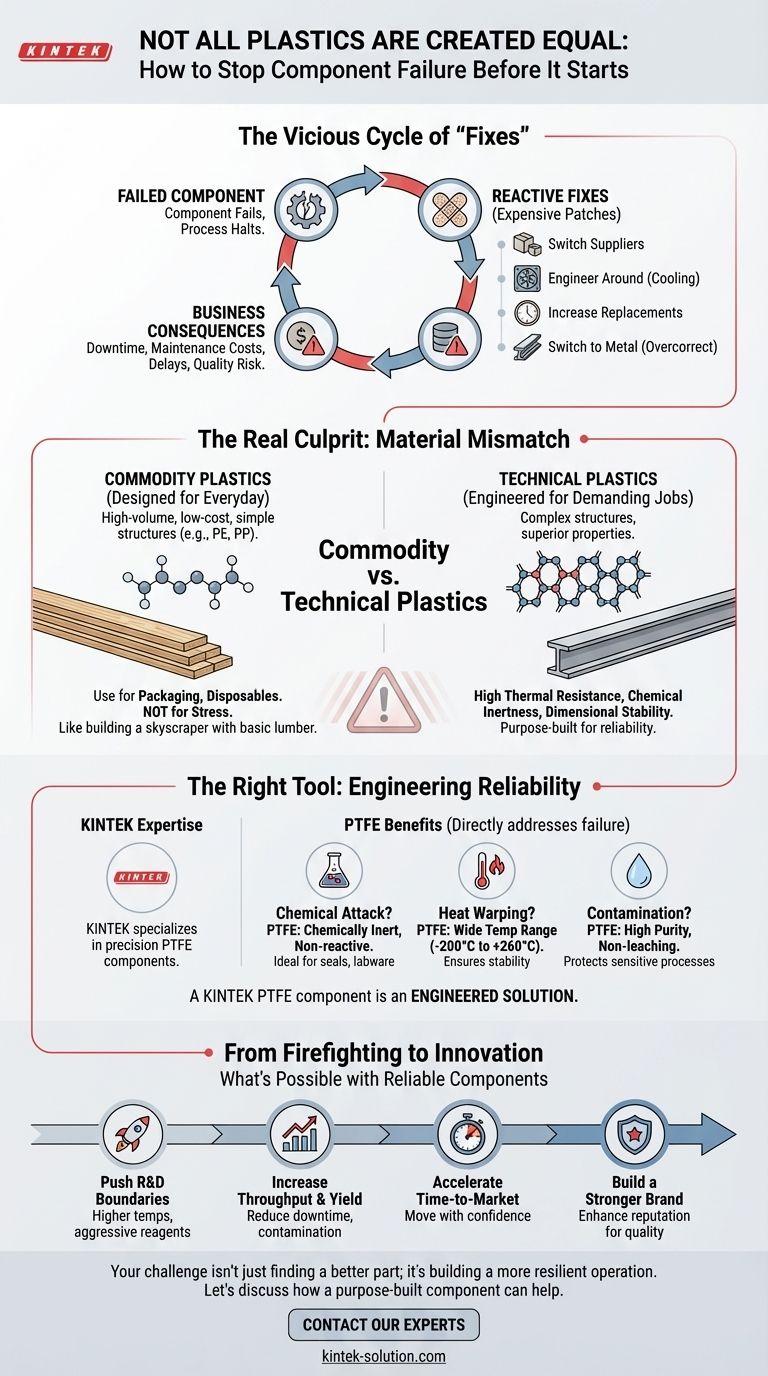

The Vicious Cycle of "Fixes" That Don't Fix Anything

If this sounds familiar, you’re not alone. When a plastic component fails, the typical response is a series of reactive, short-term fixes. Perhaps you try:

- Switching suppliers, hoping for a "better quality" version of the same cheap material.

- "Engineering around" the problem, by adding cooling systems or reducing operating temperatures, compromising your process efficiency.

- Increasing the replacement frequency, accepting component failure as a routine operational cost.

- Overcorrecting by switching to metal, introducing new challenges like higher weight, potential corrosion, and significantly increased costs.

These are not solutions; they are expensive patches. They treat the symptom—a failed part—while completely ignoring the disease. This cycle of misdiagnosis leads to tangible business consequences: unpredictable downtime, spiraling maintenance budgets, delayed R&D cycles, and a constant risk to your product quality and reputation.

The Real Culprit: A Fundamental Material Mismatch

Here is the turning point: the problem isn't that you chose a "bad" plastic. The problem is that you may have chosen the wrong category of plastic for the job.

The world of polymers isn't a simple binary of "cheap" vs. "expensive." It’s a spectrum of materials engineered for specific purposes. The core issue behind most unexpected component failures lies in misunderstanding the fundamental difference between two of these categories: commodity plastics and technical plastics.

Commodity Plastics: Designed for the Everyday

Commodity plastics like Polyethylene (PE) and Polypropylene (PP) are masterpieces of high-volume, low-cost manufacturing. They are perfect for things like packaging, bottles, and disposable containers. Their chemical structure is designed for simplicity and cost-effectiveness, not for performance under stress. Using them in a demanding industrial or scientific application is like using basic construction lumber to build the foundation of a skyscraper. It’s not a matter of if it will fail, but when.

Technical Plastics: Engineered for Demanding Jobs

Technical plastics, on the other hand, are developed from the ground up for performance. They are designed to function as reliable, load-bearing, and long-lasting components in demanding environments. Their molecular structure is intentionally complex to deliver a superior combination of properties that commodity plastics simply cannot provide:

- High Thermal Resistance: They maintain their shape and strength at temperatures that would cause commodity plastics to soften and warp.

- Chemical Inertness: They resist degradation from exposure to aggressive chemicals, solvents, and oils.

- Dimensional Stability: They can be machined to extremely tight tolerances and will hold that precise shape, even under mechanical stress or temperature fluctuations.

This is why the "fixes" mentioned earlier always fail. Trying a different supplier of a commodity plastic is just swapping one type of inadequate lumber for another. The material itself is fundamentally mismatched for the application's demands.

The Right Tool for the Job: Engineering Reliability from the Molecule Up

To truly solve the problem of component failure, you must move from reactive replacement to proactive design. This means selecting a material that is not just "strong enough," but was purpose-built for the specific challenges of your application.

This is where a high-performance technical plastic like Polytetrafluoroethylene (PTFE) becomes the obvious, engineered solution, not just an expensive alternative. It is the product of a deep understanding of why other materials fail.

At KINTEK, we specialize in fabricating precision components from PTFE precisely because its properties directly address the root causes of failure in critical applications:

- Is your component failing due to chemical attack? PTFE is one of the most chemically inert substances known, making it the ideal choice for seals, liners, and labware in semiconductor or aggressive chemical processing.

- Is heat causing your parts to warp and fail? PTFE has an extremely wide operating temperature range (from -200°C to +260°C), ensuring stability where other plastics would deform.

- Are you concerned about contamination or purity? High-purity grades of PTFE are exceptionally non-reactive and non-leaching, protecting the integrity of sensitive medical, laboratory, and semiconductor processes.

A KINTEK PTFE component isn't just a piece of plastic. It's a solution born from a deep understanding of material science, precision-machined to ensure that the material's inherent strengths translate into real-world reliability.

From Firefighting to Innovation: What's Possible with Reliable Components

Once you eliminate the chronic issue of component failure, you reclaim your most valuable resources: time, budget, and focus. Instead of constantly reacting to problems, your team can:

- Push the Boundaries of R&D: Run processes at higher temperatures or with more aggressive reagents, knowing your components can handle it.

- Increase Throughput and Yield: Drastically reduce unplanned downtime and batch contamination, leading to more predictable and profitable operations.

- Accelerate Time-to-Market: Move from prototype to production with confidence, free from the delays caused by unreliable parts.

- Build a Stronger Brand: Deliver products that are more durable and reliable, enhancing your reputation for quality and engineering excellence.

Your challenge isn't just finding a better part; it's building a more resilient, capable, and innovative operation. That process begins by choosing the right materials for the right reasons. If your projects demand uncompromising performance, let's discuss how a purpose-built component can become the strongest link in your system. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- How PTFE Solves Critical Industrial Challenges Through Material Superiority