< ![CDATA[

The Anatomy of a Million-Dollar Failure

Imagine a state-of-the-art pharmaceutical cleanroom. The air is filtered to near-perfection. Every surface is sterile. Inside a bioreactor, a multi-million-dollar batch of a life-saving biologic is nearing completion.

Then, the unseen happens. A valve diaphragm, stressed by thousands of cycles and harsh sterilization chemicals, develops a microscopic fissure. It begins to leach trace compounds into the process stream. The failure is invisible to the naked eye, yet it compromises the entire batch.

The choice of a material for a simple component like a valve diaphragm isn't just a mechanical decision; it's a strategic one that governs risk for the entire operation. It reveals a deeper truth: in high-stakes manufacturing, the smallest details have the largest systemic impact.

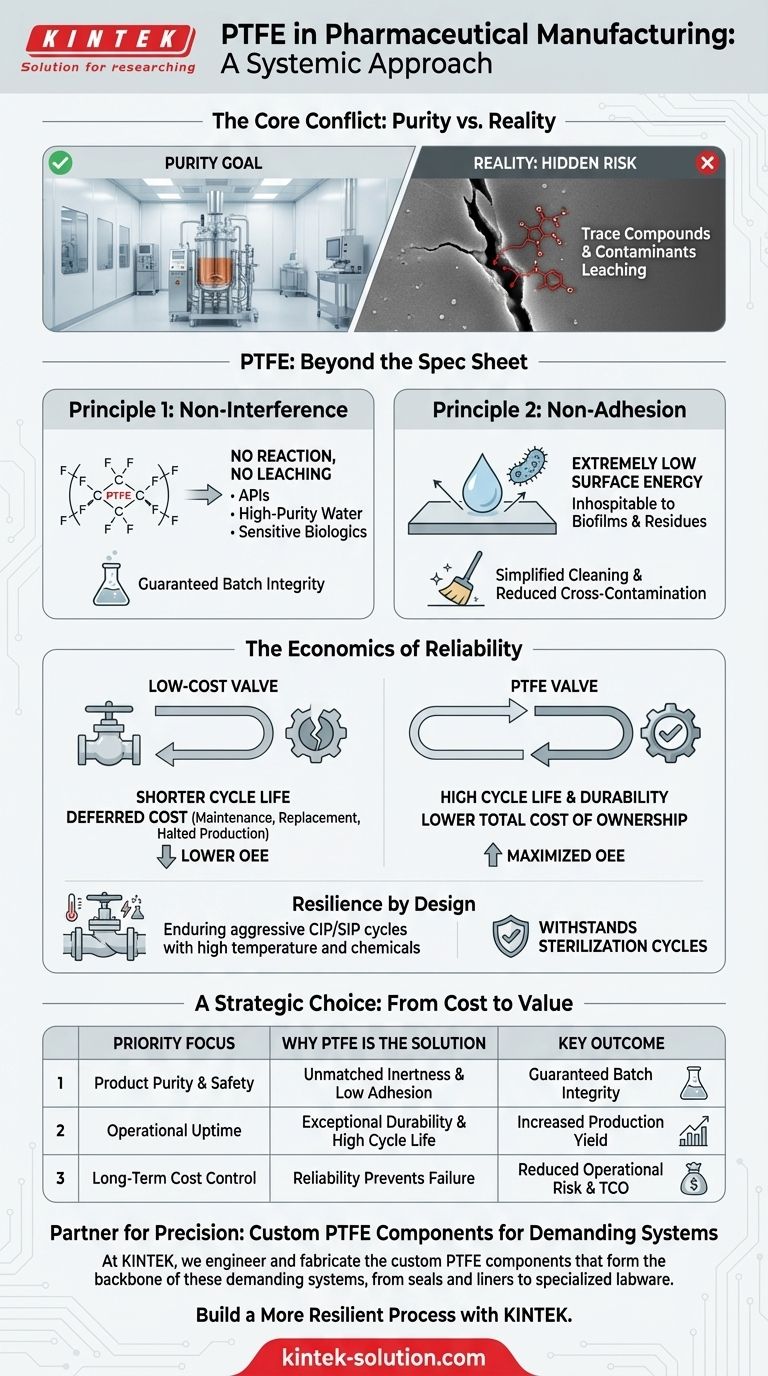

Purity vs. Reality: The Core Conflict

Pharmaceutical manufacturing is a constant battle against physical and chemical reality. The goal is absolute purity and predictability. The reality is that every material introduced into the process is a potential point of failure or contamination.

This is where Polytetrafluoroethylene (PTFE) transcends its role as a mere material. It becomes a foundational element of process integrity, addressing the industry's most critical challenges at a fundamental level.

The Principle of Non-Interference

The first promise of any component in a pharmaceutical line is to do no harm—to not alter the medium it controls. PTFE fulfills this promise through its near-total chemical inertness.

It does not react with, corrode from, or leach into Active Pharmaceutical Ingredients (APIs), high-purity water, or sensitive biologics. This isn't just a feature; it is a guarantee of non-interference. It ensures the final product's chemical signature remains pristine, a non-negotiable for efficacy and regulatory approval.

The Principle of Non-Adhesion

Contamination is not always chemical; it can be biological. The formation of microbial biofilms is a persistent threat, capable of causing cross-contamination between batches.

PTFE has extremely low surface energy, creating a "non-stick" surface at a microscopic level. It is a surface designed to be inhospitable to adhesion. Bacteria and process residues struggle to gain a foothold, which drastically simplifies cleaning cycles and reduces the risk of hidden contaminants surviving from one batch to the next.

The Economics of Reliability

The second battle is against downtime. In a high-volume manufacturing environment, every minute of unplanned stoppage translates into lost capacity and revenue. This is where we often fall for a common psychological bias: focusing on visible, upfront costs while ignoring the larger, invisible costs of future failure.

The True Cost of a Single "Cycle"

A valve's life is measured in cycles—the number of times it can open and close before failing. A valve with a lower initial cost but a shorter cycle life is not cheaper; its cost is simply deferred, paid for later in maintenance labor, replacement parts, and halted production.

PTFE's remarkable durability and high cycle life transform a valve diaphragm from a consumable part into a long-term, reliable asset. This longevity directly reduces the frequency of failure, maximizing Overall Equipment Effectiveness (OEE) and creating a more predictable, profitable operation.

Resilience by Design: Surviving Sterilization

To maintain a sterile environment, equipment must endure repeated, aggressive sterilization cycles—Clean-in-Place (CIP) and Sterilize-in-Place (SIP). These processes use harsh chemicals and high temperatures that can degrade lesser materials.

PTFE withstands these conditions without losing its structural integrity or performance characteristics. This resilience ensures the sterile boundary of the system remains absolute, cycle after cycle.

A Strategic Choice: From Cost to Value

When selecting components, the decision framework must evolve beyond the initial price tag. The real evaluation is about managing risk and maximizing long-term value.

| Priority Focus | Why PTFE is the Strategic Solution | Key Outcome |

|---|---|---|

| Product Purity & Safety | Unmatched chemical inertness and a low-adhesion surface eliminate contamination at its source. | Guaranteed batch integrity |

| Operational Uptime | Exceptional durability and high cycle life minimize maintenance-related downtime. | Increased production yield |

| Long-Term Cost Control | Reliability and longevity drastically lower the Total Cost of Ownership (TCO) by preventing failure. | Reduced operational risk |

This shift in perspective—from short-term cost to long-term systemic stability—is the hallmark of a mature and robust manufacturing strategy.

Achieving this level of reliability requires more than just choosing the right material; it demands components manufactured with absolute precision. For industries where purity and performance are paramount—from semiconductors to medicine—partnering with a specialist in high-performance materials is critical. At KINTEK, we engineer and fabricate the custom PTFE components that form the backbone of these demanding systems, from seals and liners to specialized labware.

To build a more resilient, compliant, and profitable manufacturing process, start with the components designed to prevent failure from the start. Contact Our Experts ]]>

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- Your "Inert" PTFE Component Might Be the Real Source of System Failure