The Engineer's Dilemma: Perfect Protection vs. Practical Reality

Imagine you're designing a system to handle fuming nitric acid. A leak isn't an inconvenience; it's a catastrophic failure. Your mind immediately races to find the most robust, most chemically invulnerable solution.

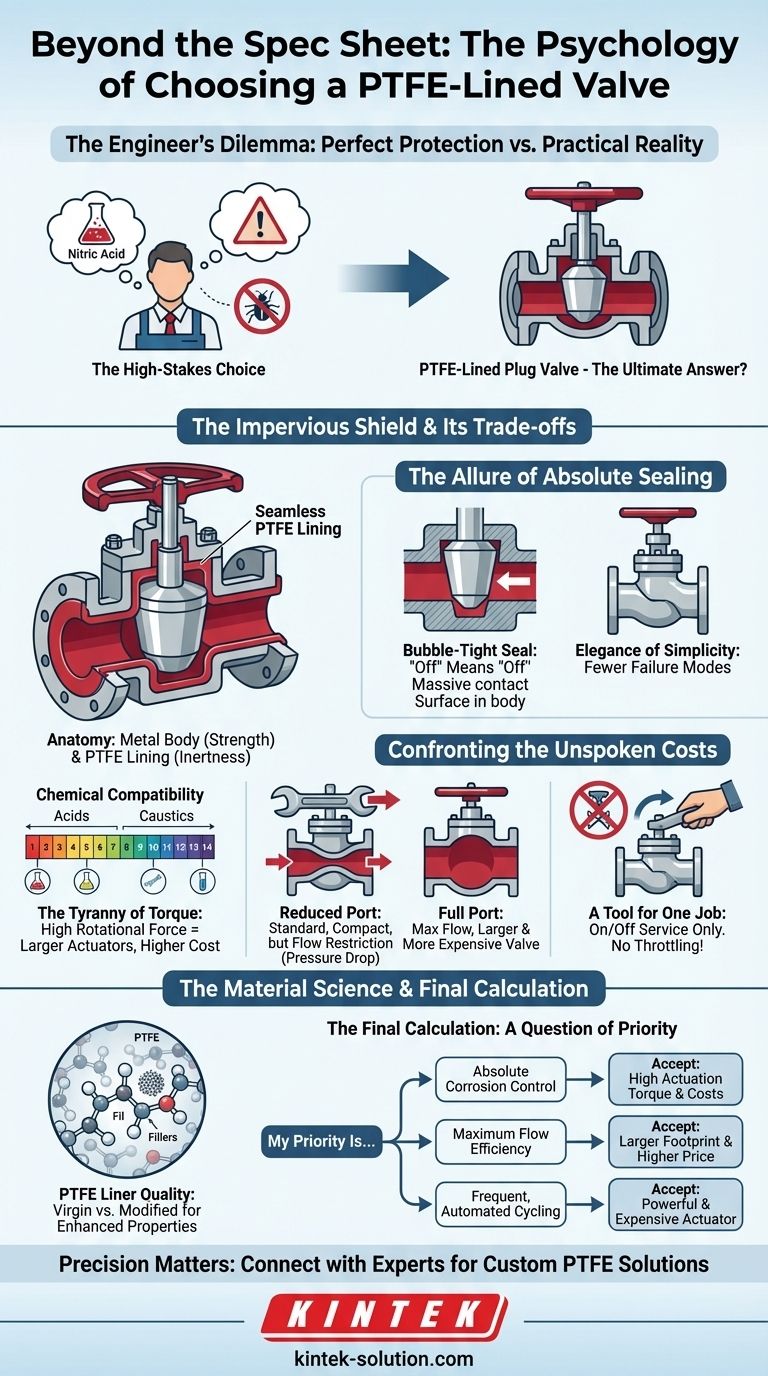

There is a powerful psychological pull toward absolute certainty in high-stakes engineering. We seek a "perfect barrier"—a component so fundamentally inert that it eliminates a whole class of risks. This search often leads directly to the PTFE-lined plug valve. It feels like the ultimate answer, a fortress of chemical resistance.

But engineering is never about a single perfect feature. It is always a story of meticulously weighed trade-offs.

The Anatomy of an Impervious Shield

The principle behind a PTFE-lined valve is brilliantly simple: isolate the process from the structure. The valve's metal body, typically cast iron or steel, provides the mechanical strength, but it never touches the aggressive media.

Instead, the fluid only interacts with a thick, seamless lining of Polytetrafluoroethylene (PTFE). It's a complete encapsulation, creating a chemically pure pathway. The elegance lies in using two materials for what they do best—steel for strength, and PTFE for inertness.

Why PTFE? The Virtue of Inertness

PTFE's reputation is almost mythical. It is virtually immune to the entire pH scale, from the most corrosive acids to the most aggressive caustics. For an engineer, this property is deeply reassuring. It removes the complex and expensive calculus of exotic metal alloys and replaces it with one, simple answer for chemical compatibility.

The Allure of Absolute Sealing

The tangible benefits of this design appeal directly to our desire for control and reliability in a system.

The Certainty of a Bubble-Tight Seal

A plug valve doesn't just close; it wedges. A tapered plug fits snugly into a matching tapered body. This creates a massive surface area of contact between the two PTFE-lined components, resulting in an exceptionally secure, bubble-tight seal.

For handling hazardous or high-purity media, this isn't just a feature—it's peace of mind. It is the physical guarantee that "off" means "off."

The Elegance of Simplicity

Compared to more complex gate or globe valves, the plug valve is a study in minimalism. Fewer moving parts mean fewer potential failure modes. This inherent simplicity leads to remarkable durability and reduces maintenance from a battle against corrosion to a simple check of the lining's integrity.

Confronting the Unspoken Costs

However, the very design choices that create this perfect shield also introduce significant physical consequences. These aren't flaws; they are the price of uncompromising protection.

The Tyranny of Torque

This is the valve's most significant trade-off. That massive sealing surface, pressed together under pressure, generates immense static friction. Despite PTFE's slickness, a very high amount of rotational force—or torque—is required to "break" the plug free and turn it.

This has a direct impact on cost and complexity, especially in automated systems. High torque demands larger, more powerful, and more expensive actuators. What seems like a simple valve choice suddenly dictates the size and cost of its control system.

The Port Size Paradox

The path the fluid takes through the valve presents another critical choice, pitting flow efficiency against cost and size.

- Reduced Port: This is the standard, most common design. The opening through the plug is smaller than the pipe's internal diameter. It is a compact and cost-effective design, but it acts as a permanent bottleneck, creating a pressure drop and restricting flow.

- Full Port: This design offers an unrestricted flow path equal to the pipe's diameter. It is the ideal choice for maximizing flow and minimizing pressure loss, but it comes at the cost of a physically larger, heavier, and more expensive valve.

A Tool for One Job

Like a ball valve, a plug valve is a quarter-turn device built for one purpose: on/off service. Using it to throttle or regulate flow is a misapplication. Attempting to hold it in a partially open position will cause uneven wear on the PTFE lining and result in poor, unpredictable control.

The Material Science Within: Not All Liners Are Equal

The performance of the entire valve assembly—its durability, its temperature limits, its very integrity—hinges on the quality of its single most critical component: the PTFE liner.

Pure, virgin PTFE is chemically supreme but mechanically soft. To enhance its rigidity, wear resistance, and stability under pressure and temperature changes, manufacturers often use modified PTFE with fillers like glass or carbon.

This is a science in itself. The choice of filler enhances mechanical properties but can alter others, like electrical conductivity. The integrity of a valve designed to last for decades begins with the molecular integrity and precision molding of its liner.

This is where specialized manufacturing is indispensable. At KINTEK, we focus on the precision fabrication of these critical PTFE components. We understand that whether it's a seal, a lab component, or a valve liner for a corrosive chemical plant, the performance of the final assembly is determined by the quality of its core parts. We craft custom PTFE components, from prototype to high-volume production, ensuring they meet the exact specifications demanded by the most challenging environments.

The Final Calculation: A Question of Priority

Choosing a PTFE-lined plug valve is less a technical decision and more a declaration of your system's primary goal.

The final choice requires you to answer one question: What do I value most?

| If Your Priority Is... | Then You Must Accept... |

|---|---|

| Absolute Corrosion Control | The high actuation torque and its associated costs. |

| Maximum Flow Efficiency | The larger footprint and higher price of a full-port design. |

| Frequent, Automated Cycling | The need for a powerful and expensive actuator. |

The most reliable systems are built by engineers who look beyond the spec sheet and understand the deep-seated trade-offs of their choices. The protection offered by a PTFE-lined valve is unparalleled, but only when its operational demands are fully understood and accounted for.

For systems where failure is not an option, the precision of every component matters. If you are designing equipment that relies on the unparalleled performance of PTFE, ensure your components are crafted to the highest standard. Contact Our Experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

Related Articles

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics