It’s two hours before kickoff. The stadium is quiet, but the pressure is on. Your team is making the final preparations, but the line-marking machine is spitting and sputtering again, leaving a messy, dotted trail instead of a crisp, professional line. The mower you just serviced is already leaving slightly torn, stressed grass blades in its wake.

For groundskeepers and facility managers, this scenario is more than just frustrating—it's a recurring nightmare that undermines their expertise and hard work. You invest in good equipment and train your people, yet these persistent issues keep happening.

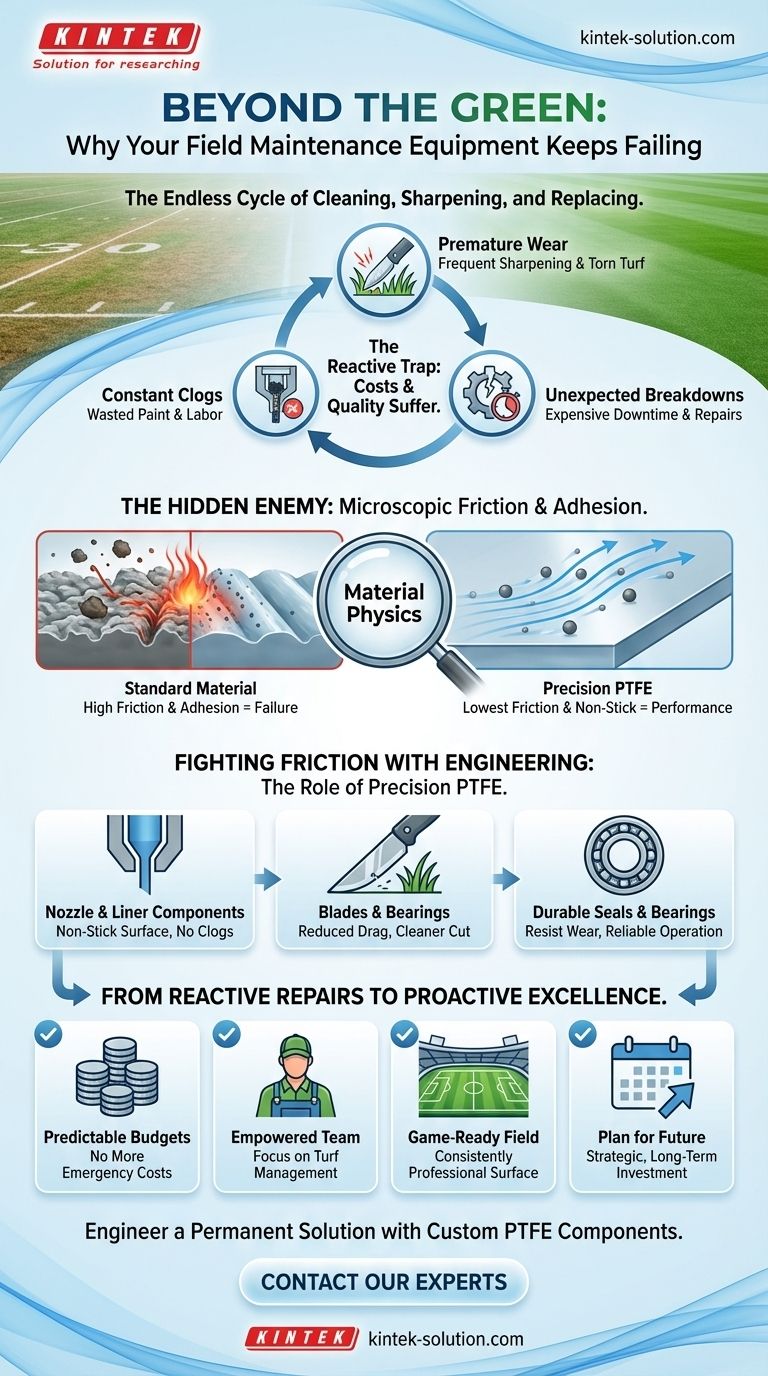

The Endless Cycle of Cleaning, Sharpening, and Replacing

If you're in charge of maintaining a professional-grade athletic field, you're likely fighting a constant, costly battle against your own tools. This battle looks something like this:

- Constant Clogs: Your team spends valuable time dismantling and cleaning paint nozzles that seem determined to clog, wasting paint and labor on re-dos.

- Premature Wear: Mower blades dull faster than they should, leading to frequent sharpening or replacement. The result is a bruised, torn cut that stresses the turf and can lead to browning.

- Unexpected Breakdowns: Bearings and seals in your machinery wear out prematurely, causing expensive downtime at the worst possible moments—like right before a major event.

These aren't just minor inconveniences; they have direct business consequences. The costs add up quickly: wasted paint, higher labor expenses, frequent orders for replacement parts, and increased fuel consumption from inefficient machines. More importantly, the quality of your field—a direct reflection of your institution's standards—suffers. You're stuck in a reactive loop, constantly fixing symptoms instead of preventing the problem.

The Hidden Enemy: Why Your Tools Are Working Against You

The common assumption is that these are separate issues: a paint problem, a blade problem, a mechanical problem. We try to solve them with better cleaning protocols, more frequent sharpening, and heavier lubrication. But these are just temporary fixes.

The real culprit is a single, fundamental force of physics that these common solutions fail to address: material friction and adhesion at a microscopic level.

The Science of Failure

- In Your Line Marker: Paint is chemically designed to adhere to surfaces. When it flows through a standard metal or plastic nozzle, that same property causes it to build up, layer by layer, until the passage is blocked. You aren't fighting bad paint; you're fighting the very nature of adhesion.

- On Your Mower Blades: As a metal blade cuts through grass, the friction generates heat and creates microscopic drag. This not only requires more energy (tearing the grass instead of slicing it) but also accelerates the dulling of the cutting edge.

- Inside Your Bearings: Even with lubrication, intense friction between moving parts causes wear and tear over time. Standard seals and bearings eventually succumb to this constant stress, leading to mechanical failure.

The "common solutions" only treat the aftermath—the clog, the dull blade, the worn-out part. They never address the root cause: a surface material that is inherently susceptible to friction and adhesion.

Fighting Friction with Engineering: The Role of Precision PTFE

To permanently solve this problem, you don't need a better cleaning schedule. You need a better material. You need a surface so inherently slick that paint can't stick to it and friction becomes a non-issue.

This is where Polytetrafluoroethylene (PTFE) comes in. Known for having one of the lowest coefficients of friction of any solid, PTFE is an engineering marvel. It is exceptionally non-stick and chemically inert, making it the ideal material for defeating the hidden enemy in your equipment.

This isn't just about applying a "non-stick coating." It's about fundamentally re-engineering the critical points of failure. At KINTEK, we don't just supply PTFE; we are material science experts who manufacture precision-engineered PTFE components designed to solve these specific challenges. Our products are not an afterthought—they are the solution, built from a deep understanding of the problem.

- For Clogging Nozzles: We fabricate custom PTFE liners and nozzle components. Their non-stick surface ensures a consistent, uninterrupted flow of paint from start to finish. No more clogs.

- For Inefficient Mowers: Our expertise in PTFE application on blades and in self-lubricating bearings drastically reduces friction. This delivers a cleaner, healthier cut for the turf while extending the service life of the machinery.

- For Premature Breakdowns: We manufacture durable PTFE seals and bearings that resist wear and chemical degradation, ensuring your equipment runs reliably when you need it most.

From Reactive Repairs to Proactive Excellence

Once you solve the core problem of friction and adhesion, the entire dynamic of your field maintenance operation changes. You break free from the cycle of reactive repairs and unlock a new level of efficiency and quality.

Imagine a world where:

- Budgets are predictable. You're no longer blindsided by the costs of emergency repairs, wasted materials, and excessive labor.

- Your team is empowered. Instead of fighting their tools, your groundskeepers can focus their expertise on advanced turf management and perfecting the field's aesthetic.

- Your field is always game-ready. Equipment reliability means you can execute pre-game preparations with confidence, delivering a consistently professional-grade surface that becomes a source of pride.

- You can plan for the future. Instead of just keeping things running, you can strategically invest in long-term improvements, knowing your core equipment is built to last.

Solving these persistent equipment frustrations isn't about working harder; it's about working smarter by using the right materials in the right places.

Your challenges are unique, from the specific equipment you use to the performance standards you must meet. The generic, off-the-shelf part is often just a temporary patch for a deeper issue. Let's move beyond temporary fixes and engineer a permanent solution for your most critical equipment. To discuss how custom PTFE components can eliminate your most persistent maintenance headaches and elevate your operational efficiency, Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Scrapers and Shovels for Demanding Applications

Related Articles

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- How PTFE Solves Critical Industrial Challenges Through Material Superiority