In a multi-million-dollar semiconductor fabrication plant, a single microscopic particle can ruin an entire batch of wafers. In a life-saving medical device, a component loosening by a fraction of a millimeter can mean failure.

The causes of these catastrophic events are often not grand, systemic breakdowns. They are frequently traced back to the smallest, most overlooked components. A fastener. A seal. Or the tiny, unassuming washer sitting between them.

The choice of a washer is more than a line item on a bill of materials. It's an exercise in foresight. It's a psychological bet against the forces—pressure, vibration, and rotation—that relentlessly try to pull our machines apart.

When the environment is corrosive, the temperatures extreme, or the surfaces delicate, the material of choice is often PTFE. But simply choosing the material is only half the battle.

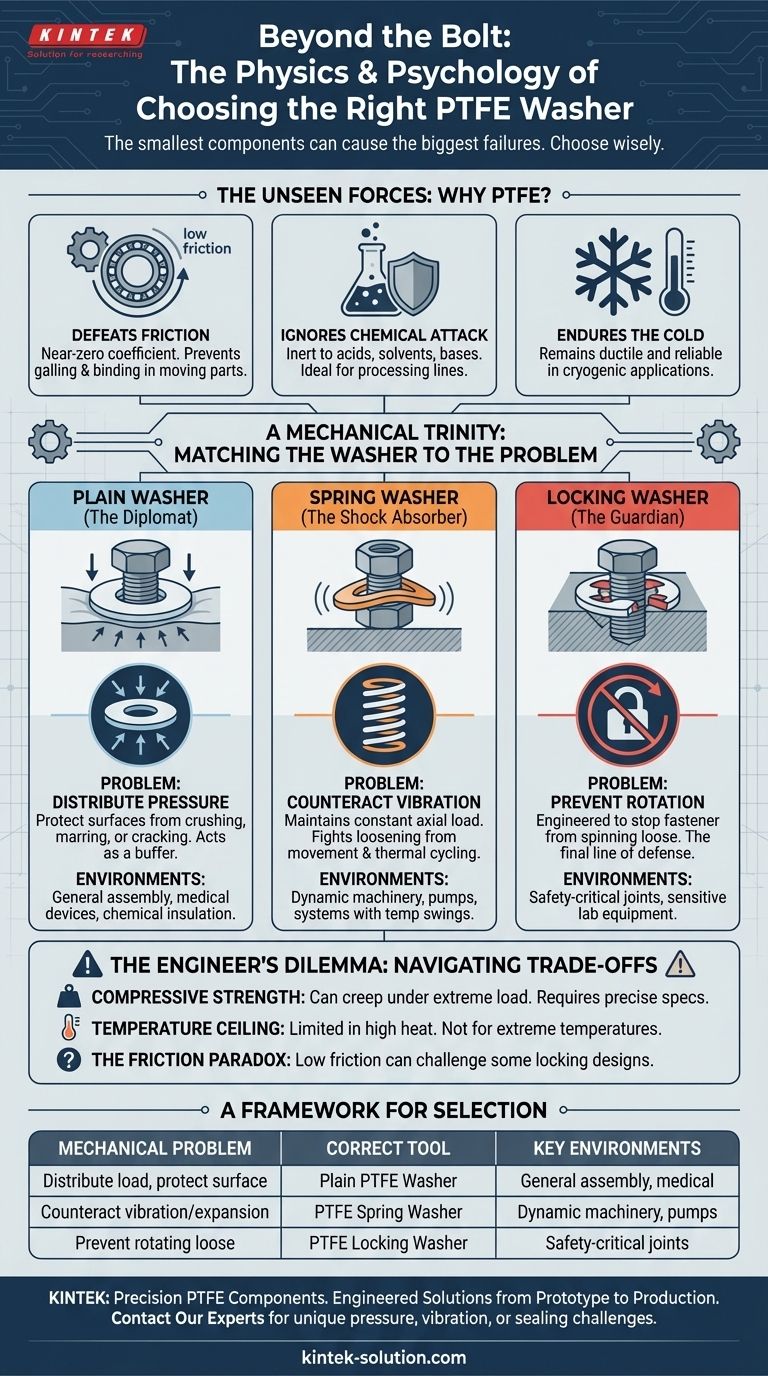

The Unseen Forces: Why We Turn to PTFE

Before we dissect the type of washer, we must understand the why. Polytetrafluoroethylene (PTFE), the material behind the Teflon™ brand, isn't just a replacement for metal. It's a solution for problems where metal is the liability.

- It Defeats Friction: In assemblies with moving or rotating parts, PTFE's near-zero coefficient of friction isn't a feature; it's an enabler of longevity. It prevents the galling and binding that slowly destroy mechanical systems.

- It Ignores Chemical Attack: For components in laboratory equipment or chemical processing lines, PTFE's inertness is a superpower. It sits unphased by acids, solvents, and bases that would dissolve the most robust alloys.

- It Endures the Cold: While other polymers become brittle and shatter, PTFE remains ductile and reliable in cryogenic applications. It provides a trustworthy seal when everything else is frozen solid.

PTFE is the engineer's choice when the environment is hostile. The next question is, which specific tool do you need for the job?

A Mechanical Trinity: Matching the Washer to the Problem

The decision between a plain, spring, or locking washer is a diagnosis of the primary threat your assembly will face. Each is a specialized tool designed to counteract a specific mechanical force.

H3: The Diplomat: Plain Washers and the Art of Distributing Pressure

A plain PTFE washer is the foundation. It's a simple, flat disc, but its function is profoundly important: to act as a diplomat between two surfaces.

The concentrated force under a screw head or a nut can crush, mar, or crack the surface of a component, especially softer materials like plastics or composites. The plain washer takes that immense pressure and distributes it over a wider area, preventing damage.

In a medical device, it protects a polymer housing. In a semiconductor tool, it insulates a sensitive component from electrical or chemical contact. Its job is to keep the peace and maintain surface integrity.

H3: The Shock Absorber: Spring Washers and the Battle Against Vibration

No machine is truly static. Motors hum, fluids pulse, and temperatures fluctuate. This constant state of micro-movement and vibration is the natural enemy of a tightened fastener.

A PTFE spring washer is not flat. It's intentionally deformed to act like a spring, generating a constant axial load. This tension is its weapon.

It fights back against the loosening effects of vibration and thermal cycling. By maintaining a continuous preload, it ensures the fastener stays put, providing reliability in the most dynamic and corrosive environments. It's designed for a world that never stops shaking.

H3: The Guardian: Locking Washers and the Tyranny of Torque

Sometimes, the most direct threat is pure rotational force. A fastener that spins loose can lead to immediate, catastrophic failure.

A locking washer is engineered with a single purpose: to prevent this rotation. While metal versions often use teeth that bite into the substrate, PTFE locking washers can employ clever geometry or frictional properties to achieve the same end.

They are the final line of defense in safety-critical assemblies where maintaining torque is non-negotiable. They add a layer of security, ensuring that what has been tightened stays tightened.

The Engineer's Dilemma: Navigating the Trade-Offs

PTFE is a remarkable material, but it is not a panacea. Acknowledging its limitations is the mark of an experienced engineer.

- Compressive Strength: PTFE is soft. Under extreme clamping forces, it can deform or "creep" over time, causing a loss of bolt tension. This is where material grade and dimensional precision are critical.

- Temperature Ceiling: Its excellence in cold is matched by a limitation in heat. For high-temperature applications, other materials are required.

- The Friction Paradox: The low friction that makes PTFE ideal for rotating applications can sometimes challenge locking washer designs that depend on static friction to work.

Navigating these trade-offs requires more than just picking a part from a catalog. It requires a deep understanding of material science and manufacturing precision. It's about tailoring the component—its exact dimensions, purity, and form—to the specific stresses of the application.

A Framework for Selection

The right choice becomes clear when you define the primary problem you need to solve.

| The Mechanical Problem | The Correct Tool | Key Environments |

|---|---|---|

| Distribute load, protect a surface | Plain PTFE Washer | General assembly, chemical insulation, medical devices |

| Counteract vibration or expansion | PTFE Spring Washer | Dynamic machinery, pumps, systems with temperature swings |

| Prevent fastener from rotating loose | PTFE Locking Washer | Safety-critical joints, sensitive lab equipment |

Ultimately, selecting the right washer is a microcosm of the entire design process: understanding the forces at play, anticipating failure modes, and choosing a component with the precise properties to ensure integrity and longevity.

At KINTEK, we focus on manufacturing precision PTFE components that solve these exact challenges for the semiconductor, medical, and industrial sectors. From prototypes to high-volume production, we ensure your components are not just parts, but engineered solutions. If you're facing a unique challenge involving pressure, vibration, or sealing, Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

Related Articles

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- Beyond "Non-Stick": Why Your PTFE Components Fail and How to Fix It for Good

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems