In the world of automotive engineering, few materials solve as many critical challenges as Polytetrafluoroethylene (PTFE). It is widely used because its unique combination of properties—high-temperature stability, extreme chemical resistance, and an exceptionally low coefficient of friction—makes it the ideal material for components that must survive harsh environments while ensuring efficiency and preventing leaks.

The core reason for PTFE's prevalence in the automotive industry is not one single attribute, but its rare ability to simultaneously resist heat, fight chemical corrosion, and minimize friction, making it indispensable for creating reliable and efficient seals, gaskets, and linings.

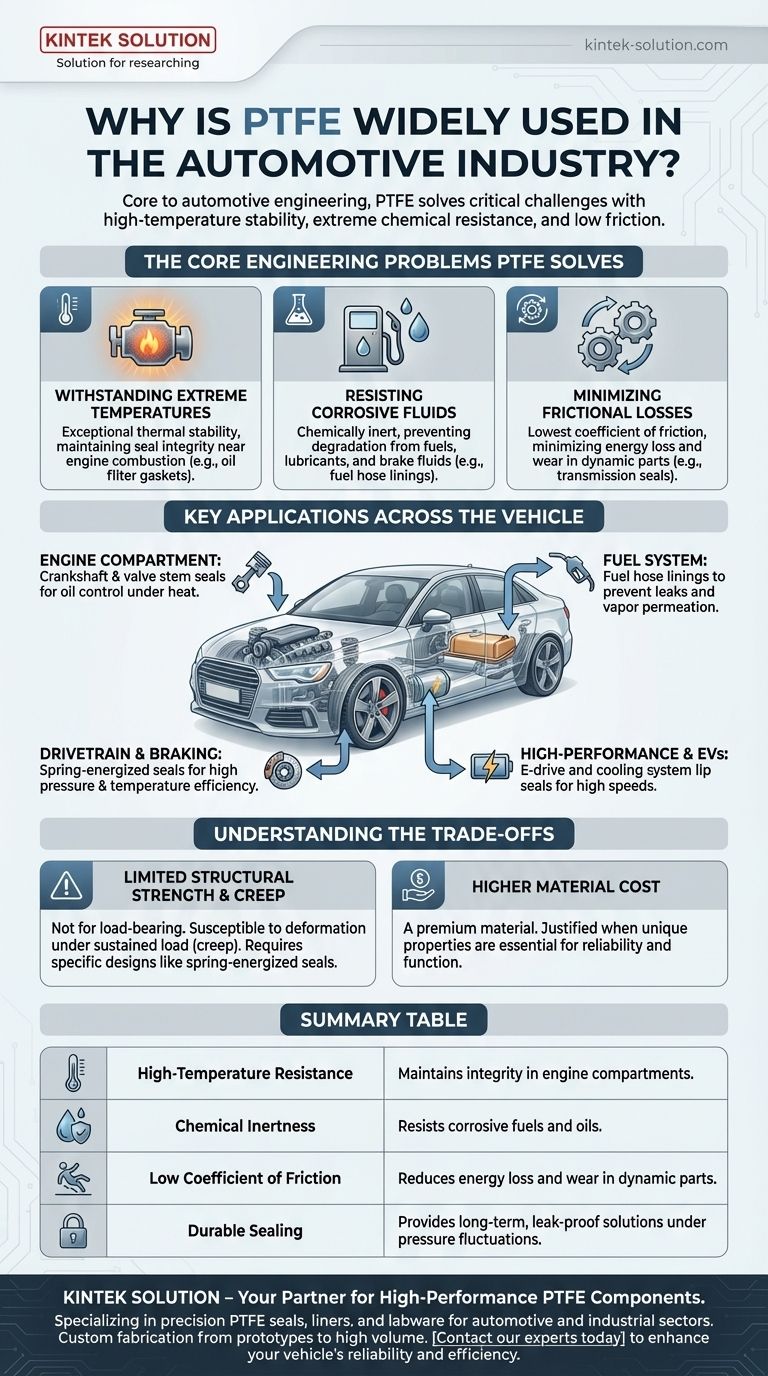

The Core Engineering Problems PTFE Solves

PTFE is not just a material choice; it is a solution to fundamental challenges in vehicle performance and longevity. Engineers specify it to address issues that common plastics and elastomers cannot handle.

Withstanding Extreme Temperatures

Many automotive components operate in environments with intense heat, particularly within the engine compartment.

PTFE has exceptional thermal stability and high-temperature resistance. This allows it to maintain its integrity and sealing capability in direct proximity to engine combustion, such as in gaskets for oil filters and fuel pumps.

Resisting Corrosive Fluids

A vehicle relies on a range of aggressive fluids, including fuels, lubricants, oils, and braking fluids, which can degrade lesser materials over time.

PTFE is almost completely chemically inert. This makes it the perfect choice for fuel hose linings and seals, as it does not break down or react when exposed to corrosive chemicals, preventing leaks and ensuring system integrity.

Minimizing Frictional Losses

Efficiency is a primary goal in modern vehicle design. Friction between moving parts leads to energy loss, heat generation, and component wear.

With one of the lowest coefficients of friction of any solid material, PTFE is an ideal surface for dynamic applications. It is used in rotary shaft lip seals, guide strips, and transmission components to minimize energy loss and extend the lifespan of parts.

Ensuring Long-Term Sealing and Reliability

Seals and gaskets are critical for preventing fluid leaks and maintaining pressure in systems like engines, transmissions, and brakes.

PTFE provides durable, leak-proof solutions that are dependable over a long lifespan. Spring-energized PTFE seals, for example, provide effective sealing under high pressure and temperature fluctuations, enhancing overall vehicle reliability.

Key Applications Across the Vehicle

PTFE is found in nearly every critical system of a modern car, from the engine to the electric drivetrain.

In the Engine Compartment

The engine is the most demanding environment. PTFE is used for engine crankshaft seals to prevent oil leaks and for valve stem seals to control oil consumption, all while withstanding extreme heat and pressure.

In the Fuel System

To ensure safe and efficient fuel delivery, PTFE is used as a lining in fuel hoses. Its chemical resistance prevents the fuel from degrading the hose and stops fuel vapor from permeating through the material.

In Drivetrain and Braking Systems

In transmissions and braking systems, PTFE seals must manage high pressures and temperatures while minimizing friction. Spring-energized seals and guide strips are used here to enhance efficiency and reliability.

For High-Performance and Electric Vehicles (EVs)

The demands of high-performance vehicles amplify the need for superior materials. PTFE lip seals are used in NASCAR engine drive shafts and, increasingly, in the e-drive and cooling systems of electric vehicles that operate at very high speeds.

Understanding the Trade-offs

While its benefits are significant, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Limited Structural Strength

PTFE is a relatively soft material and is not suitable for load-bearing structural applications. Its value is as a seal, lining, or low-friction surface, often integrated with stronger metal or polymer components.

Susceptibility to Creep

Under a sustained load, especially at elevated temperatures, PTFE can slowly deform over time. This phenomenon, known as creep, must be accounted for in component design, which is why designs like spring-energized seals exist to maintain constant pressure.

Higher Material Cost

Compared to common elastomers and plastics, PTFE is a premium material with a higher cost. Its use is therefore justified in applications where its unique performance is not just beneficial, but absolutely necessary for the vehicle's function and reliability.

Making the Right Choice for Your Goal

Selecting PTFE should be a deliberate decision based on specific engineering requirements.

- If your primary focus is maximizing efficiency and reducing wear: Use PTFE for its low-friction properties in dynamic components like shaft seals, guide strips, and transmission parts.

- If your primary focus is ensuring reliability in high-heat environments: Specify PTFE for engine components like crankshaft seals and gaskets that are exposed to high temperatures and corrosive fluids.

- If your primary focus is fluid containment and chemical resistance: Leverage PTFE's inertness for fuel hose linings and any seal that comes into contact with aggressive lubricants or fuels.

Understanding how to leverage PTFE's distinct profile of thermal, chemical, and frictional resistance is key to solving some of the most difficult challenges in modern vehicle design.

Summary Table:

| Property | Benefit in Automotive Applications |

|---|---|

| High-Temperature Resistance | Maintains integrity in engine compartments (e.g., crankshaft seals). |

| Chemical Inertness | Resists corrosive fuels and oils (e.g., fuel hose linings). |

| Low Coefficient of Friction | Reduces energy loss and wear in dynamic parts (e.g., transmission seals). |

| Durable Sealing | Provides long-term, leak-proof solutions under pressure and temperature fluctuations. |

Need high-performance PTFE components for your automotive application?

KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for the automotive, semiconductor, medical, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact our experts today to discuss how our PTFE solutions can enhance your vehicle's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications