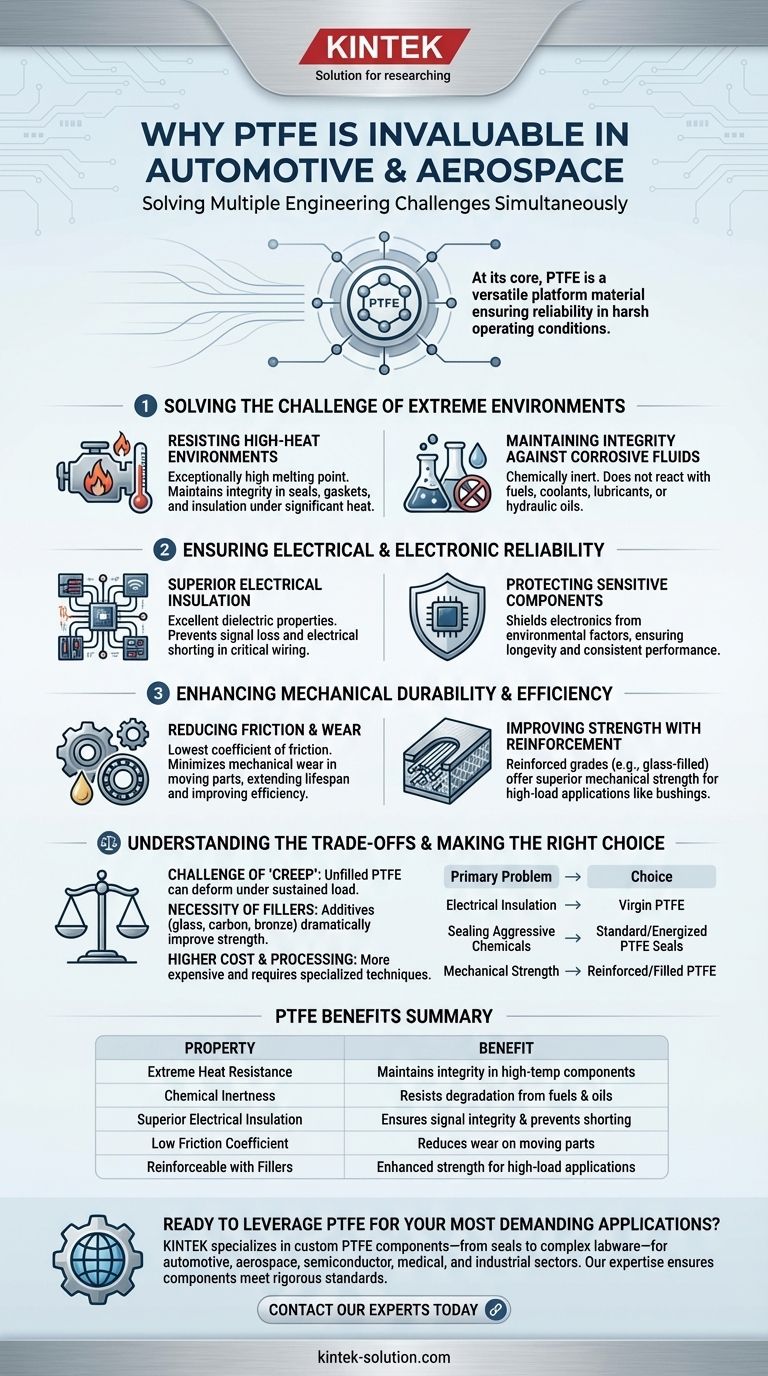

At its core, Polytetrafluoroethylene (PTFE) is invaluable to the automotive and aerospace industries because of its unique ability to solve multiple, simultaneous engineering challenges. Its combination of extreme heat resistance, chemical inertness, low friction, and superior electrical insulation makes it one of the few materials that can ensure reliability in the harsh operating conditions common to both sectors.

These industries face a constant battle against failure caused by heat, friction, corrosion, and electrical faults. PTFE is not just a single solution but a versatile platform material that directly addresses these critical failure points, from engine seals to high-altitude wiring.

Solving the Challenge of Extreme Environments

The fundamental value of PTFE lies in its stability when conditions become unstable. It maintains its integrity where lesser materials would quickly degrade and fail.

Resisting High-Heat Environments

Most plastics soften or melt in the high-temperature environments of an engine bay or aerospace component. PTFE, however, possesses an exceptionally high melting point.

This property allows it to be used for seals, gaskets, and wire insulation in locations that experience significant heat, ensuring components remain functional and safe.

Maintaining Integrity Against Corrosive Fluids

Automotive and aerospace systems rely on a variety of aggressive fluids, including fuels, coolants, lubricants, and hydraulic oils.

PTFE is almost completely chemically inert, meaning it will not react with or break down when exposed to these corrosive substances. This makes it the ideal material for seals and fluid-handling components that must not degrade over time.

Ensuring Electrical and Electronic Reliability

In an era of increasingly complex electronics, maintaining signal integrity and preventing electrical failure is paramount for safety and performance.

Superior Electrical Insulation

Nearly half of all PTFE produced is used for wiring, particularly in aerospace and computing. Its excellent dielectric properties prevent signal loss and electrical shorting.

It serves as a high-performance substitute for materials like polyethylene, especially in critical applications like hook-up wires and coaxial cables where reliability is non-negotiable.

Protecting Sensitive Components

As an insulator, PTFE shields sensitive electronic parts from environmental factors. This protection ensures the longevity and consistent performance of control systems and other vital electronics.

Enhancing Mechanical Durability and Efficiency

Beyond its static properties, PTFE plays a crucial role in the performance of moving parts, directly impacting efficiency and lifespan.

Reducing Friction and Wear

PTFE has one of the lowest coefficients of friction of any solid material. This "slipperiness" is essential for parts like bushings and seals in moving components.

By reducing friction, PTFE parts minimize mechanical wear, which in turn extends the life of the vehicle or aircraft and can even improve fuel efficiency.

Improving Strength with Reinforcement

For high-load applications, standard PTFE can be reinforced with fillers like glass fiber.

This creates a composite material, such as glass-filled PTFE, with superior mechanical strength and wear resistance. It is frequently used in demanding suspension components like bushings or thrust washers that must bear heavy, dynamic loads.

Understanding the Trade-offs

While incredibly versatile, PTFE is not a universal solution. Understanding its limitations is key to using it effectively.

The Challenge of 'Creep'

Unfilled, virgin PTFE can be susceptible to "creep," a tendency to slowly deform over time when under a sustained load. This makes it unsuitable for certain structural applications where dimensional stability is critical.

The Necessity of Fillers for Mechanical Use

The issue of creep is precisely why reinforced grades exist. Adding fillers like glass, carbon, or bronze dramatically improves mechanical strength and resistance to wear, making PTFE suitable for dynamic, load-bearing roles.

Higher Cost and Processing

As a high-performance fluoropolymer, PTFE is more expensive than common commodity plastics. Its processing also requires specialized techniques and equipment compared to more conventional materials.

Making the Right Choice for Your Application

Selecting the correct form of PTFE is essential for project success. Your choice depends entirely on the primary problem you are trying to solve.

- If your primary focus is electrical insulation at high frequencies: Virgin PTFE is the definitive choice for applications like coaxial cables and high-performance wiring.

- If your primary focus is sealing against aggressive chemicals and heat: Standard or energized PTFE seals will provide reliable performance where traditional elastomers would fail.

- If your primary focus is mechanical strength and wear resistance: A filled grade, such as glass-filled PTFE, is necessary for components like bushings, bearings, and thrust washers.

By understanding these distinct applications, you can leverage PTFE not just as a material, but as a strategic solution for ensuring reliability in the most demanding environments.

Summary Table:

| Property | Benefit for Automotive & Aerospace |

|---|---|

| Extreme Heat Resistance | Maintains integrity in engine bays and high-temperature components. |

| Chemical Inertness | Resists degradation from fuels, oils, and hydraulic fluids. |

| Superior Electrical Insulation | Ensures signal integrity and prevents shorting in critical wiring. |

| Low Friction Coefficient | Reduces wear on moving parts, improving efficiency and lifespan. |

| Reinforceable with Fillers | Enhanced strength for high-load applications like bushings and bearings. |

Ready to leverage PTFE for your most demanding applications?

KINTEK specializes in the precision manufacturing of custom PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your components meet the rigorous standards of automotive and aerospace environments.

Contact our experts today to discuss how our PTFE solutions can enhance your product's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability