At its core, Polytetrafluoroethylene (PTFE) is the industry standard for cap liners because of its unique and powerful combination of properties. It offers near-universal chemical resistance, exceptional stability across a wide range of temperatures, and physical characteristics that create a secure, non-contaminating seal.

The true value of PTFE is not just its ability to create a seal, but its ability to do so while remaining almost completely invisible to the process. It protects the container's contents from the outside world without introducing any new variables from the liner itself.

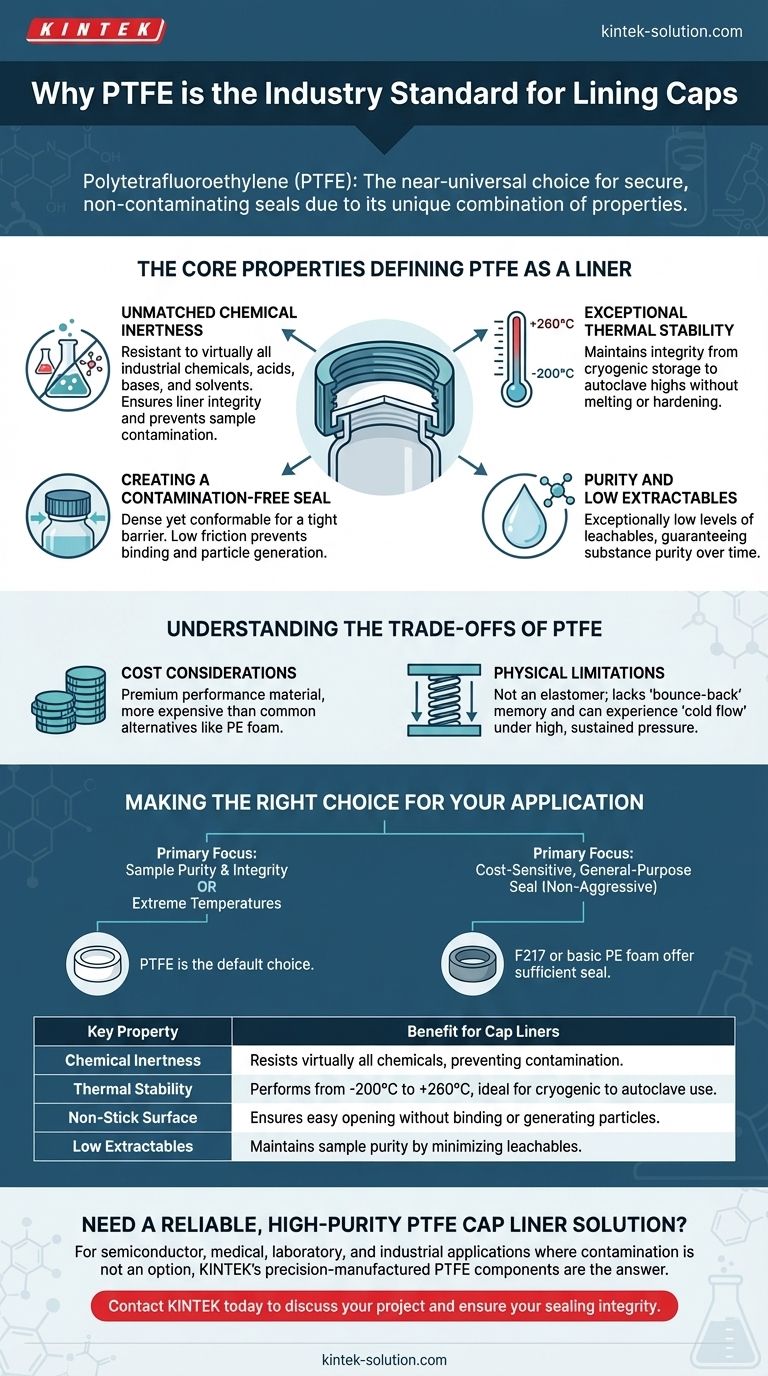

The Core Properties Defining PTFE as a Liner

The dominance of PTFE is not accidental; it is a direct result of its molecular structure. This structure gives it three key advantages that are difficult to replicate in a single material.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. It is resistant to virtually all industrial chemicals, acids, bases, and solvents.

This inertness is critical because it ensures the liner will not degrade upon contact with the container's contents. More importantly, it prevents the liner from contaminating the sample, which is paramount in analytical, pharmaceutical, and high-purity applications.

Exceptional Thermal Stability

The material maintains its integrity and sealing properties across an extreme temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This allows PTFE-lined caps to be used for everything from cryogenic storage to high-temperature applications like autoclaving and depyrogenation without melting, hardening, or losing their seal.

Creating a Contamination-Free Seal

PTFE is a dense but relatively soft fluoropolymer. This allows it to conform to the rim of a container, creating a tight physical barrier against leaks and evaporation.

Furthermore, its famously low coefficient of friction (the property that makes it non-stick) prevents the liner from binding or sticking to the container. This ensures easy opening and closing without damaging the seal or generating particulate matter.

Purity and Low Extractables

A critical factor in scientific and manufacturing contexts is the concept of "extractables and leachables." These are chemicals that can migrate from a container or liner into the product.

PTFE has exceptionally low levels of extractables. This guarantees that the substance being stored remains pure and is not tainted by impurities leaching from the cap liner over time.

Understanding the Trade-offs of PTFE

While PTFE is a superior material for demanding applications, it is not the universal solution for every scenario. Understanding its limitations is key to making an informed decision.

Cost Considerations

PTFE is a premium performance material, and its cost reflects that. It is significantly more expensive than common alternatives like polyethylene (PE) foam or rubber liners.

For general-purpose applications involving non-reactive substances, a less expensive liner is often a more economical and perfectly adequate choice.

Physical Limitations

PTFE is not an elastomer. It does not have the "bounce-back" memory of rubber, meaning it is less suited for applications requiring frequent resealing where a liner's elasticity is key to its function.

Under very high, sustained mechanical pressure, PTFE can also be subject to "cold flow" or creep, where the material slowly deforms over time. This is rarely an issue in standard cap applications but can be a factor in specialized high-pressure systems.

Making the Right Choice for Your Application

Selecting the correct liner requires balancing performance needs with budget constraints. The choice becomes clear when you define your primary objective.

- If your primary focus is preserving sample purity and integrity: PTFE is the default choice due to its extreme chemical inertness and low extractables.

- If your primary focus is performance across a wide temperature range: PTFE's stability from cryogenic lows to autoclave highs makes it the most reliable option.

- If your primary focus is a cost-sensitive, general-purpose seal: For non-aggressive or dry substances, simpler liners like F217 (a three-ply liner with a PE foam core) or basic PE foam offer a sufficient seal at a lower cost.

Ultimately, choosing PTFE is an investment in certainty, ensuring your container's seal is never a variable in the quality of your work.

Summary Table:

| Key Property | Benefit for Cap Liners |

|---|---|

| Chemical Inertness | Resists virtually all chemicals, preventing contamination. |

| Thermal Stability | Performs from -200°C to +260°C, ideal for cryogenic to autoclave use. |

| Non-Stick Surface | Ensures easy opening without binding or generating particles. |

| Low Extractables | Maintains sample purity by minimizing leachables. |

Need a Reliable, High-Purity PTFE Cap Liner Solution?

For semiconductor, medical, laboratory, and industrial applications where contamination is not an option, KINTEK's precision-manufactured PTFE components are the answer. We specialize in custom fabricating PTFE seals, liners, and labware—from prototypes to high-volume orders—to meet your exact specifications for performance and purity.

Contact KINTEK today to discuss your project and ensure your sealing integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- When and by whom was PTFE discovered? A Tale of Accidental Innovation