In the field of material science, Polytetrafluoroethylene (PTFE) is a premier choice for coating machine parts due to its unique combination of an extremely low coefficient of friction, high heat resistance, and broad chemical inertness. This trifecta of properties allows it to reduce mechanical wear, protect components from corrosive agents, and maintain stability in demanding operational environments.

The true value of a PTFE coating is not a single feature, but the synergy of its extreme slipperiness, chemical resistance, and thermal stability. This makes it a definitive solution for protecting moving parts in nearly any harsh industrial setting.

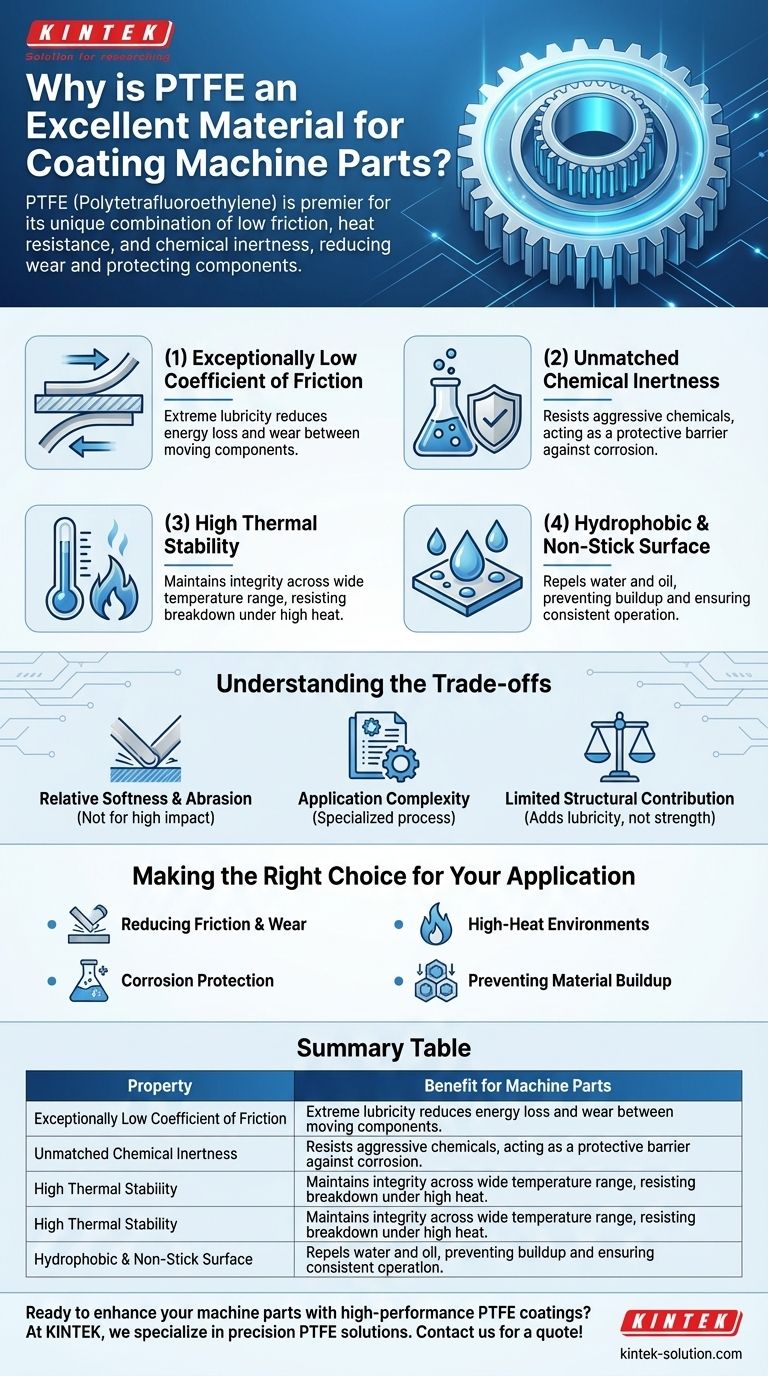

The Core Properties of PTFE Coatings

To understand why PTFE is so effective, we must look beyond the surface benefits and analyze the fundamental properties that deliver its performance.

Exceptionally Low Coefficient of Friction

PTFE is famous for being one of the most slippery materials known to science. This is its defining characteristic.

This extreme lubricity, or "slipperiness," dramatically reduces the energy lost to friction between moving components. This translates directly to less wear and tear on parts that slide, rotate, or engage with one another.

Unmatched Chemical Inertness

PTFE exhibits a remarkable resistance to a vast range of chemicals, including aggressive acids, alkalis, and organic solvents.

This property means the coating acts as a protective barrier, shielding the underlying metal of the machine part from corrosion and chemical attack that would otherwise cause it to degrade and fail.

High Thermal Stability

The material maintains its integrity and properties across a wide temperature range, possessing a relatively high melting point.

This thermal stability ensures the coating will not break down, melt, or lose its effectiveness on components that are subjected to significant heat during operation.

Hydrophobic and Non-Stick Surface

Due to its low surface tension, PTFE is both hydrophobic (repels water) and oleophobic (repels oil). This is the source of its well-known non-stick qualities.

For machine parts, this prevents moisture intrusion and stops other materials from adhering to the surface, which is critical for preventing buildup and ensuring clean, consistent operation.

Excellent Dielectric Strength

PTFE is also an outstanding electrical insulator, meaning it does not conduct electricity.

While not always the primary reason for its selection, this property is invaluable for applications where components must be electrically isolated from their surroundings.

Understanding the Trade-offs

No material is perfect for every situation. Acknowledging the limitations of PTFE is critical for making an informed engineering decision.

Relative Softness and Abrasion

While PTFE excels at resisting frictional wear, it is a relatively soft polymer.

It is not ideal for high-impact applications or environments with abrasive particles (like sand or grit), as the coating can be physically scraped or worn away under these conditions.

Application Complexity

Applying a durable, high-performance PTFE coating is a specialized industrial process.

It requires meticulous surface preparation and controlled curing at high temperatures to ensure proper adhesion to the substrate. It is not as simple as applying a conventional paint.

Limited Structural Contribution

It is crucial to remember that PTFE is a coating, not a structural material.

While solid PTFE components are strong for their weight, a thin coating adds lubricity and protection, not strength or rigidity to the machine part itself.

Making the Right Choice for Your Application

Selecting the right coating depends entirely on your primary engineering goal.

- If your primary focus is reducing friction and wear: PTFE is an industry-leading choice for bearings, gears, and sliding mechanisms where smooth, low-energy motion is critical.

- If your primary focus is corrosion protection: The chemical inertness of PTFE makes it an ideal barrier for parts exposed to aggressive solvents, acids, or process fluids.

- If your primary focus is performance in high-heat environments: PTFE's thermal stability ensures the coating remains effective on parts operating at elevated temperatures where other lubricants would degrade.

- If your primary focus is preventing material buildup: The non-stick nature of PTFE is perfect for applications in food processing, molding, or any process where surface cleanliness is essential.

By understanding these core attributes and their trade-offs, you can strategically leverage PTFE coatings to significantly enhance the durability and performance of your machine components.

Summary Table:

| Property | Benefit for Machine Parts |

|---|---|

| Low Friction | Reduces wear and energy loss in moving components. |

| Chemical Inertness | Protects against corrosion from acids, solvents, and alkalis. |

| Thermal Stability | Maintains performance at high operating temperatures. |

| Non-Stick Surface | Prevents material buildup and ensures easy cleaning. |

| Dielectric Strength | Provides excellent electrical insulation. |

Ready to enhance your machine parts with high-performance PTFE coatings?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including custom coatings for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts benefit from reduced friction, superior chemical resistance, and extended service life.

Contact us today to discuss your specific requirements and get a quote for your project—from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability