At its core, selecting a supplier based on their PTFE lining standards is a critical risk management decision. While many suppliers use PTFE, the rigor of their manufacturing and quality control standards directly determines the final product's performance, durability, and reliability, significantly impacting the total cost of ownership.

The real issue isn't the PTFE material itself, but the supplier's process control. Inconsistent or low standards introduce unpredictable variability, turning a component from a reliable asset into a potential point of catastrophic failure.

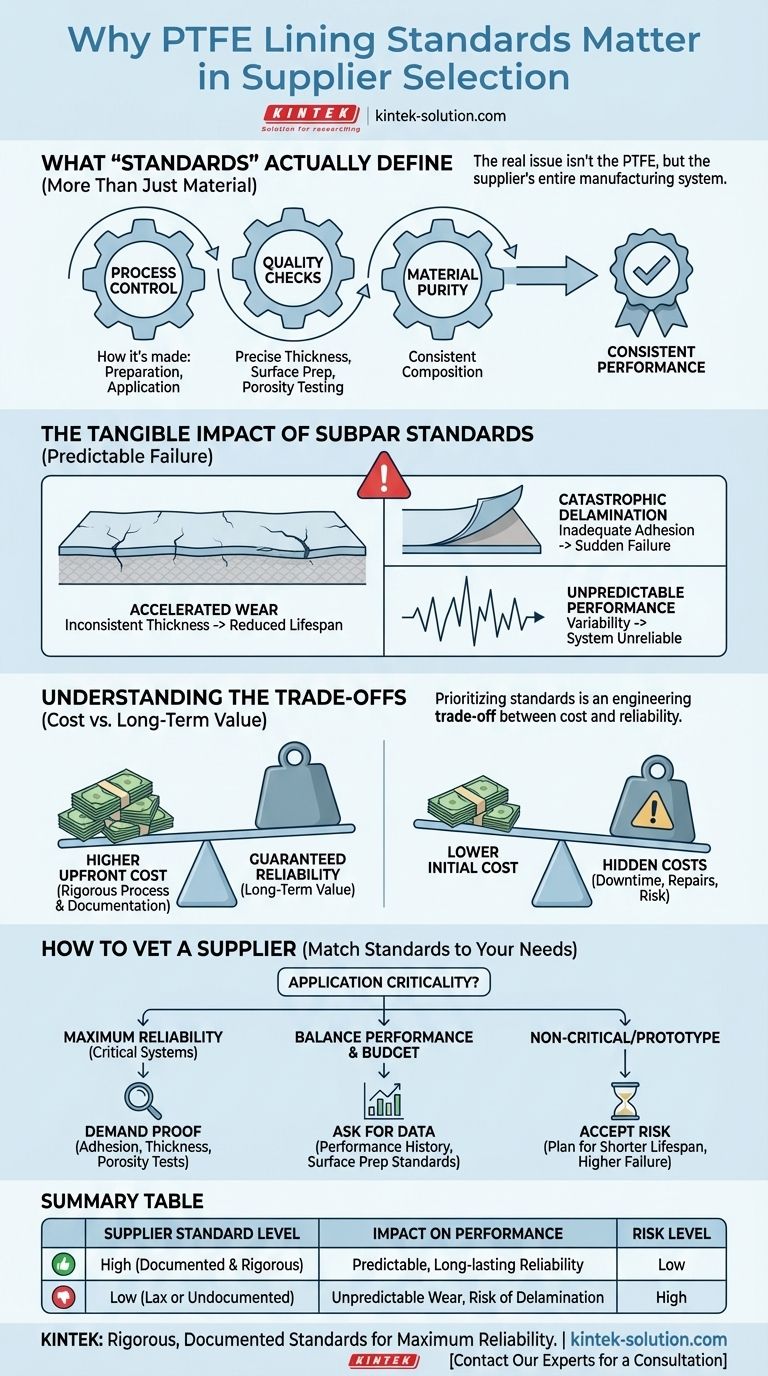

What "PTFE Lining Standards" Actually Define

The term "standards" goes far beyond simply using the correct raw material. It refers to the entire system of processes and checks a manufacturer implements to ensure quality and consistency.

The Process, Not Just the Polymer

A robust standard dictates how the PTFE is prepared, applied, and finished. This includes critical parameters that define the lining's integrity and its ability to perform under stress.

Key Elements of a High-Quality Standard

Superior suppliers codify their processes around several key metrics. These often include precise tolerances for lining thickness and uniformity, protocols for substrate surface preparation to ensure maximum adhesion, and stringent testing for porosity or pinholes that could lead to premature failure.

Material Purity and Composition

Standards also govern the quality of the PTFE itself. This ensures there are no impurities that could compromise its low-friction properties or chemical resistance, guaranteeing consistent performance from batch to batch.

The Tangible Impact of Subpar Standards

Choosing a supplier with lax or undocumented standards exposes your project to predictable and often costly failure modes. The initial cost savings are quickly erased by the consequences.

Accelerated Wear and Failure

An inconsistent lining thickness is a primary outcome of poor standards. Thinner sections will wear through rapidly, leading to a drastically reduced operational lifespan and unexpected maintenance demands.

Catastrophic Delamination

Perhaps the most significant risk is lining delamination. If a supplier's standard for surface preparation and bonding is inadequate, the PTFE lining can peel away from the base material, causing a complete and often sudden component failure.

Unpredictable Performance

Without rigorous standards, you lose predictability. One batch of components might perform perfectly, while the next fails under the exact same conditions. This variability makes it impossible to engineer a reliable system.

Understanding the Trade-offs

The decision to prioritize a supplier's standards is a classic engineering trade-off between upfront cost and long-term value.

The Cost vs. Reliability Equation

Suppliers with high standards invest heavily in process control, advanced inspection equipment, and documentation. This results in a higher initial component cost but provides a guarantee of reliability.

The Hidden Costs of Low Standards

A lower-cost component from a supplier with poor standards carries significant hidden costs. These include the expense of unplanned downtime, replacement labor, and potential damage to interconnected equipment when the component fails.

The Challenge of Verification

A key challenge is that suppliers may claim to have high standards without providing proof. True high-quality suppliers can readily provide documentation on their testing procedures, material traceability, and quality control metrics.

How to Vet a Supplier's PTFE Lining Standards

Your application's specific needs should guide your level of scrutiny when evaluating a potential supplier.

- If your primary focus is maximum reliability for a critical application: Demand detailed documentation on quality control, including specific tests for lining adhesion, thickness consistency, and porosity.

- If your primary focus is balancing performance and budget: Ask for performance data from previous projects and inquire specifically about their standards for surface preparation, as this is the most common point of failure.

- If your primary focus is a non-critical system or initial prototype: A supplier with less rigorous standards might be acceptable, but you must acknowledge and plan for a shorter component lifespan and higher potential for failure.

Ultimately, a supplier's documented standards are the most reliable predictor of a component's real-world performance and longevity.

Summary Table:

| Supplier Standard Level | Impact on Performance | Risk Level |

|---|---|---|

| High (Documented & Rigorous) | Predictable, long-lasting reliability | Low |

| Low (Lax or Undocumented) | Unpredictable wear, risk of delamination | High |

Don't let subpar PTFE lining standards compromise your critical systems. KINTEK manufactures high-performance PTFE components (seals, liners, labware) for the semiconductor, medical, laboratory, and industrial sectors. Our commitment to rigorous, documented standards ensures your components deliver maximum reliability, longevity, and value. Let's discuss your project's specific requirements—contact our experts today for a consultation on custom fabrication from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech