At its core, expanded Polytetrafluoroethylene (ePTFE) is an excellent choice for fragile or damaged flanges because it achieves a highly effective seal with very low bolt-tightening force. This unique characteristic protects compromised flanges from the stress that would crack, warp, or further damage them when using traditional gaskets, which require significant clamping pressure to function.

The fundamental advantage of ePTFE lies in its material structure. It is exceptionally soft and conformable, allowing it to flow into surface imperfections and create a tight seal with minimal bolt torque, making it the ideal solution for protecting delicate or worn equipment.

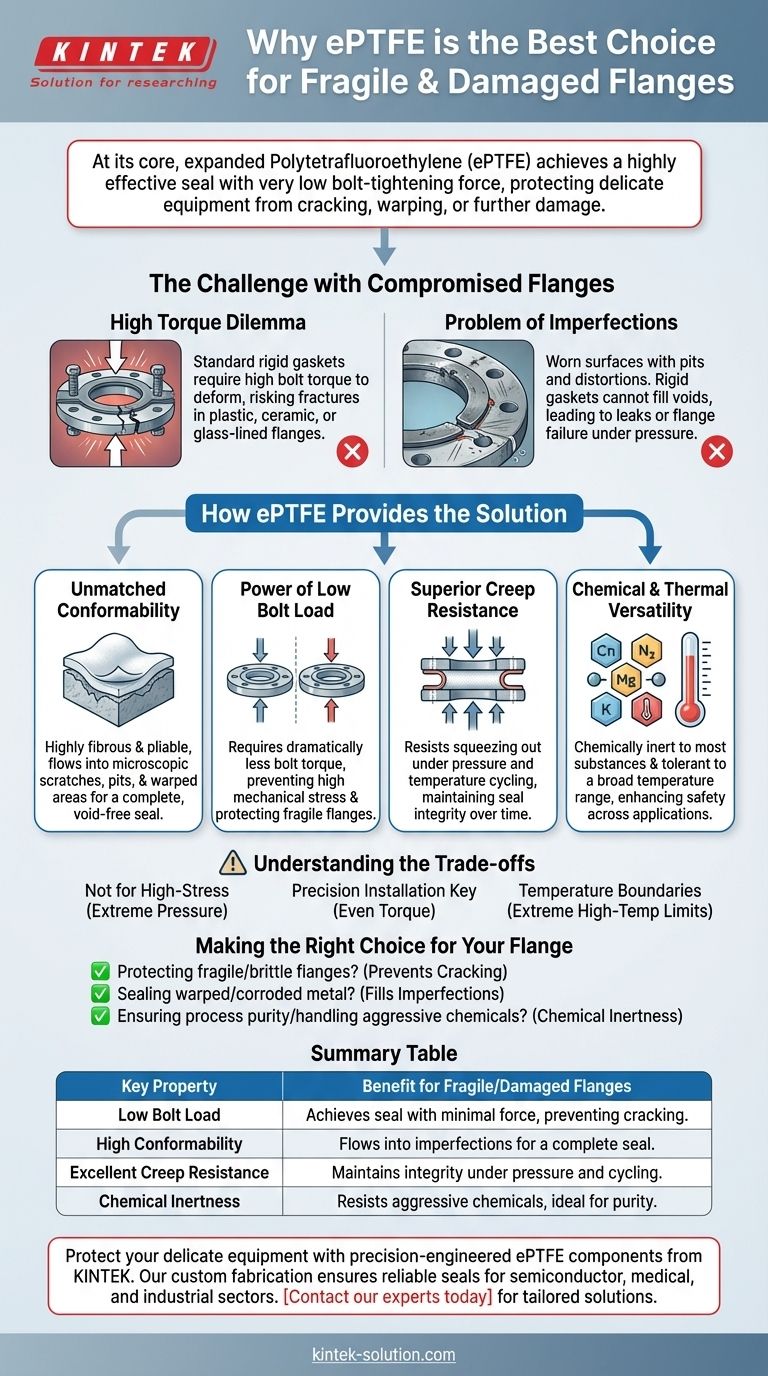

The Challenge with Compromised Flanges

To understand why ePTFE excels, we must first recognize the fundamental problem with sealing fragile or damaged flanges. The issue stems from a conflict between the gasket's needs and the flange's limitations.

The High Torque Dilemma

Standard gaskets, especially semi-metallic or metallic types, are rigid. They require a high amount of compressive force (bolt torque) to deform them enough to create a seal.

Applying this necessary force to a fragile flange—such as one made of plastic, ceramic, or glass-lined steel—can easily cause it to crack.

The Problem of Imperfections

Worn, corroded, or warped flanges have uneven surfaces full of pits, scratches, and distortions. A rigid gasket cannot fill these small voids.

Attempting to overcome this by tightening the bolts further only increases the stress on the flange, often resulting in a leak at a low-pressure point or, worse, flange failure.

How ePTFE Provides the Solution

ePTFE gasket material is engineered to overcome these exact challenges. Its properties work together to create a reliable seal without demanding high stress on the flange assembly.

Unmatched Conformability

ePTFE is a highly fibrous and pliable material. When compressed, it behaves less like a rigid sheet and more like a dense foam.

It easily flows into the microscopic scratches, pits, and warped areas of a flange face, creating a complete, void-free seal. This happens with very little applied pressure.

The Power of Low Bolt Load

Because it conforms so easily, ePTFE requires dramatically less bolt torque to achieve an initial seal. This is the single most important benefit for fragile flanges.

You can create a leak-proof joint without subjecting the flange to the high mechanical stresses that risk fracture or damage.

Superior Creep Resistance

While it is soft, ePTFE is also incredibly strong and resilient. It resists "creep," which is the tendency for a gasket material to be squeezed out of the flange over time under pressure and temperature cycling.

ePTFE can withstand high compressive stresses (up to 40,000 psi) without losing its integrity. This ensures the seal remains durable and reliable long after installation, even in demanding industrial processes.

Chemical and Thermal Versatility

Beyond its mechanical properties, ePTFE is chemically inert to almost all substances and boasts a wide temperature tolerance. This makes it a versatile solution that enhances safety and efficiency across many different applications.

Understanding the Trade-offs

While ePTFE is a superior problem-solver, it is essential to understand its operational context. No material is a universal solution.

Not a High-Stress Material

ePTFE's primary benefit is its ability to seal with low stress. It is not designed for applications that require extremely high gasket seating stress to maintain joint integrity, which is more typical for high-pressure metallic gaskets.

Installation Precision is Key

Although it is forgiving, proper installation is still critical. The flange surfaces should be clean, and the low required torque must be applied evenly and in the correct sequence to ensure the ePTFE material compresses uniformly.

Temperature Boundaries

While ePTFE has a broad operating temperature range, it is not limitless. For extreme high-temperature services (e.g., above 600°F or 315°C), other materials like graphite or specific metallic gaskets may be required.

Making the Right Choice for Your Flange

Selecting the correct gasket is about matching the material's strengths to your specific problem. ePTFE offers a unique combination of properties that make it a powerful tool for maintaining system integrity.

- If your primary focus is protecting fragile or brittle flanges: ePTFE is the definitive choice because its low bolt-load requirement prevents cracking and failure.

- If your primary focus is sealing warped or corroded metal flanges: ePTFE's superior conformability will fill surface imperfections where harder gaskets would fail, preventing leaks without risking further damage.

- If your primary focus is ensuring process purity or handling aggressive chemicals: ePTFE's chemical inertness provides a reliable seal that will not contaminate the process fluid or degrade from chemical attack.

By understanding its core benefits, you can confidently specify ePTFE to solve challenging sealing problems and ensure the long-term integrity of your equipment.

Summary Table:

| Key Property | Benefit for Fragile/Damaged Flanges |

|---|---|

| Low Bolt Load | Achieves a seal with minimal force, preventing flange cracking. |

| High Conformability | Flows into pits and scratches on uneven surfaces for a complete seal. |

| Excellent Creep Resistance | Maintains seal integrity under pressure and temperature cycling. |

| Chemical Inertness | Resists aggressive chemicals, ideal for pure processes. |

Protect your delicate equipment with precision-engineered ePTFE components from KINTEK.

Our expanded PTFE seals, liners, and labware are designed specifically for applications where low-stress sealing is critical. Whether you're in the semiconductor, medical, laboratory, or industrial sector, KINTEK provides custom fabrication from prototypes to high-volume orders to ensure your fragile or damaged flanges are sealed reliably and safely.

Contact our experts today to discuss your specific sealing challenge and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech