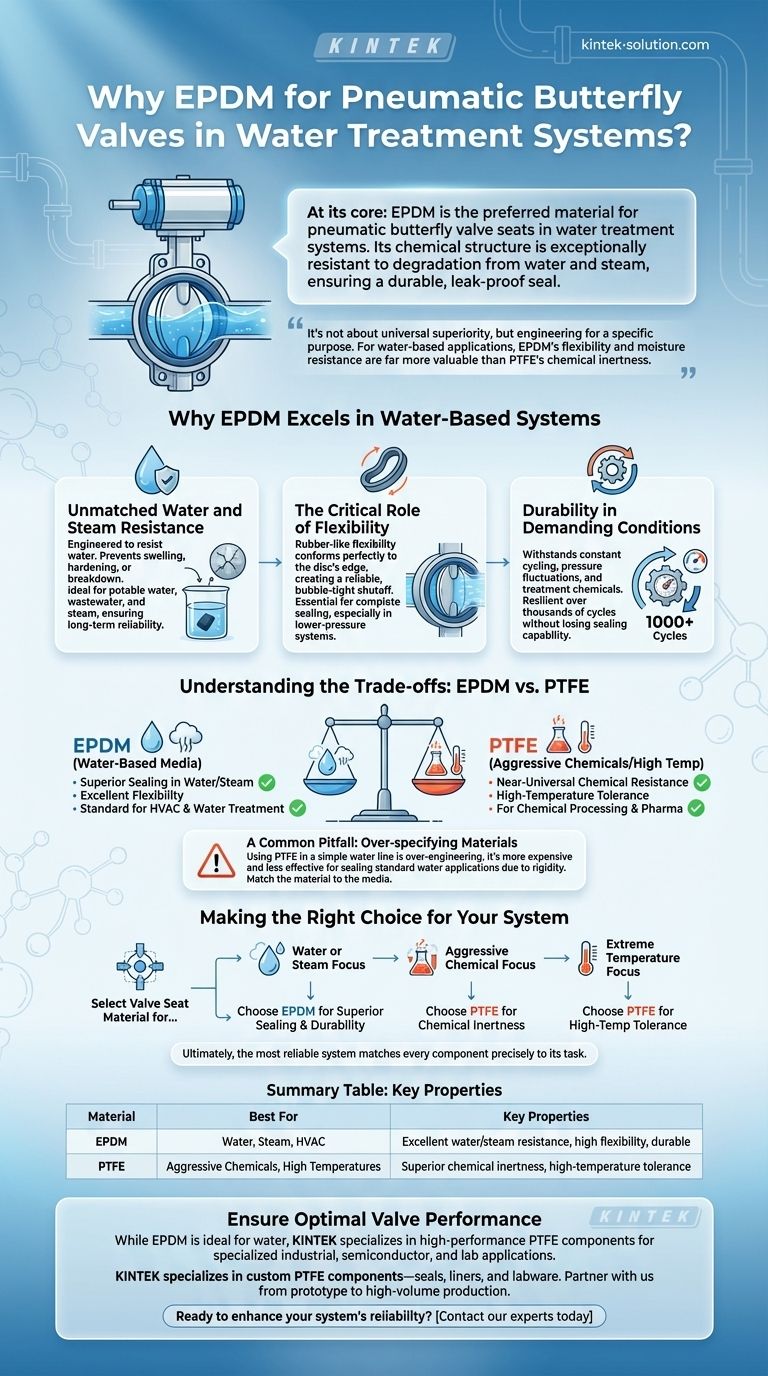

At its core, EPDM is the preferred material for pneumatic butterfly valve seats in water treatment systems because its chemical structure is exceptionally resistant to degradation from water and steam. This inherent resilience, combined with its flexibility, ensures a durable, leak-proof seal that other materials cannot reliably provide in these specific conditions.

The critical insight is not that one material is universally superior, but that each is engineered for a specific purpose. For water-based applications, EPDM's physical properties of flexibility and moisture resistance are far more valuable than the chemical inertness of materials like PTFE.

Why EPDM Excels in Water-Based Systems

The effectiveness of a valve is determined by the suitability of its soft components, primarily the seat, for the media it controls. In water treatment, EPDM's properties create a near-perfect match for the operational demands.

Unmatched Water and Steam Resistance

EPDM (Ethylene Propylene Diene Monomer) rubber is engineered to resist water. Unlike other materials that may swell, harden, or break down with prolonged exposure to moisture, EPDM maintains its structural integrity.

This makes it the default choice for applications involving potable water, wastewater, or steam, ensuring long-term reliability and preventing premature valve failure.

The Critical Role of Flexibility

A butterfly valve achieves a seal when the disc presses against the soft seat. EPDM's rubber-like flexibility is crucial here, allowing it to conform perfectly to the disc's edge.

This creates a reliable, bubble-tight shutoff. Less flexible materials can struggle to create such a complete seal, especially in lower-pressure water systems.

Durability in Demanding Conditions

Water treatment and HVAC systems are not static environments. They involve constant cycling, pressure fluctuations, and the presence of various treatment chemicals.

EPDM's resilience allows it to withstand these repetitive stresses without losing its sealing capability, providing consistent performance over thousands of cycles.

Understanding the Trade-offs: EPDM vs. PTFE

To fully appreciate why EPDM is chosen, it is helpful to compare it with another common valve seat material: PTFE (Polytetrafluoroethylene).

When to Choose EPDM

EPDM is the clear choice for water-based media. Its strengths are tailored to the physical challenges of sealing water and steam.

It is the standard for wafer and lug-style butterfly valves in HVAC, potable water systems, and industrial water treatment where extreme chemical resistance is not the primary requirement.

When PTFE is the Superior Choice

PTFE is known for its near-universal chemical resistance and high-temperature tolerance. Its purpose is to handle aggressive and corrosive chemicals or extreme temperatures that would destroy EPDM.

You will find PTFE seats in chemical processing, pharmaceuticals, or any application where the media is harsh and chemically reactive.

A Common Pitfall: Over-specifying Materials

Choosing a material based on a general sense of superiority is a frequent mistake. Using a PTFE-seated valve in a simple water line is a classic example of over-engineering.

Not only is PTFE more expensive, but its relative rigidity makes it a less effective sealing material than EPDM in standard water applications. The goal is to match the material to the media, not to simply choose the one with the highest resistance ratings.

Making the Right Choice for Your System

Selecting the correct valve seat material is a critical decision that directly impacts system performance, safety, and operational costs.

- If your primary focus is water or steam: EPDM is the industry-standard choice for its superior sealing performance, durability, and moisture resistance.

- If your primary focus is aggressive chemical processing: PTFE is the necessary option to ensure the valve seat is not degraded by the media.

- If your primary focus is extreme temperatures: PTFE offers a much wider operating temperature range and is suitable for conditions where EPDM would fail.

Ultimately, the most reliable system is one where every component is precisely selected for the specific task it must perform.

Summary Table:

| Material | Best For | Key Properties |

|---|---|---|

| EPDM | Water, Steam, HVAC | Excellent water/steam resistance, high flexibility, durable |

| PTFE | Aggressive Chemicals, High Temperatures | Superior chemical inertness, high-temperature tolerance |

Ensure Optimal Valve Performance in Your System

Choosing the right seal material is critical for efficiency and longevity. While EPDM is ideal for water and steam, many specialized industrial, semiconductor, medical, and laboratory applications require the unmatched chemical resistance of high-performance PTFE.

KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and labware—for demanding environments. We partner with you from prototype to high-volume production to deliver solutions that meet your exact specifications.

Ready to enhance your system's reliability? Contact our experts today to discuss your application requirements.

Visual Guide

Related Products

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Shallow Evaporating Dishes for Diverse Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Evaporating Dishes for Diverse Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the operational temperature limits for PTFE-lined diaphragm valves? Understanding the Full System Range

- What are the key features of PTFE diaphragms? Maximize Performance in Demanding Applications

- What are the main technical features that influence the performance of PTFE diaphragms? Optimize for Durability & Chemical Resistance

- What are the key properties of PTFE that benefit bellows and diaphragms? Achieve Unmatched Reliability in Harsh Environments

- What are the common applications of PTFE diaphragms in the Chinese market? Key Uses in Chemical, Pharma & Semiconductor