In short, correct sizing is far more critical for PTFE O-rings because they are rigid and do not stretch. Unlike a rubber O-ring, which can easily be stretched to accommodate minor size variations, a PTFE O-ring has virtually no elasticity. This fundamental difference means that a PTFE ring must be dimensionally perfect for its groove to function correctly.

The core issue is material science: rubber is an elastomer designed to stretch and conform, making it forgiving. PTFE is a plastic valued for its rigidity and resistance, which demands absolute precision in measurement and fit.

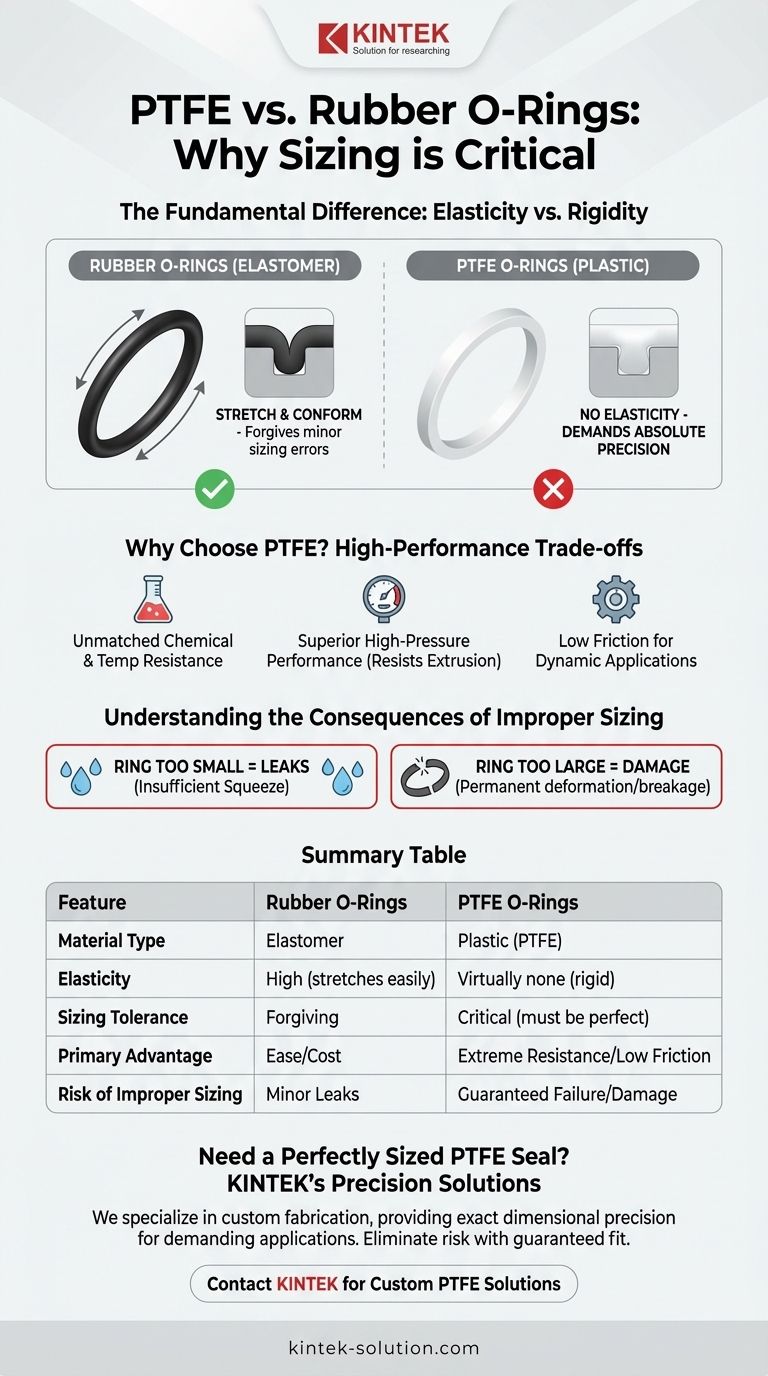

The Fundamental Difference: Elasticity vs. Rigidity

The choice between a rubber and a PTFE O-ring comes down to a trade-off between flexibility and high-performance resistance. Understanding their core material properties is key.

How Rubber O-Rings Forgive Sizing Errors

Rubber compounds are elastomers, meaning they have excellent elastic memory. They are designed to be stretched and compressed.

This flexibility allows a standard rubber O-ring to function effectively even if the groove dimensions are not perfect. It can stretch over a shaft or be squeezed into a slightly undersized groove, conforming to the space to create a reliable seal.

The Inflexible Nature of PTFE

PTFE (polytetrafluoroethylene) is a type of plastic, not an elastomer. It is valued for its rigidity and dimensional stability.

This material has very low elongation. Attempting to stretch a PTFE O-ring will cause it to permanently deform or break, rendering it useless. It must be installed by fitting it into place without significant stretching.

The Role of "Squeeze" in Sealing

An O-ring creates a seal by being compressed, or "squeezed," within its groove. This compression generates the force needed to block leaks.

With a flexible rubber ring, this squeeze is easily achieved. With a rigid PTFE ring, the necessary compression must be engineered through precise sizing. The ring and groove dimensions must be perfectly matched to achieve the correct squeeze without damaging the seal.

Why Choose PTFE Despite the Sizing Challenge?

If PTFE is so demanding, its use must be justified by significant performance advantages in specific situations.

Unmatched Chemical and Temperature Resistance

PTFE is virtually inert to most industrial chemicals and can operate reliably across an extremely wide temperature range where nearly all rubber compounds would degrade and fail.

Superior Performance in High-Pressure Systems

The rigidity of PTFE makes it highly resistant to extrusion—the process where an O-ring is forced into the clearance gap between two mating surfaces under high pressure. This makes it a superior choice for high-pressure hydraulic and pneumatic systems.

Low Friction for Dynamic Applications

PTFE has one of the lowest coefficients of friction of any solid material. This makes it ideal for dynamic seals on rotating shafts or reciprocating pistons, where a rubber O-ring would create excessive drag, heat, and wear.

Understanding the Trade-offs and Consequences

The benefits of PTFE come with strict design and installation requirements that cannot be ignored.

The High Risk of Improper Sealing

If a PTFE O-ring is even slightly too small for its groove, it will not have enough squeeze and will almost certainly leak.

If the ring is too large, it simply will not fit. Forcing it can permanently damage the ring, the groove, or both, guaranteeing a seal failure.

The Necessity of Custom Machining

With rubber, you can often find a standard size that is "close enough." With PTFE, "close enough" is not an option.

If a standard size does not perfectly match the application's requirements, a custom-machined O-ring is often the only viable solution. This can impact project cost and lead times.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary engineering goal.

- If your primary focus is general-purpose, forgiving sealing: Choose a standard rubber O-ring, as its elasticity simplifies installation and accommodates wider manufacturing tolerances.

- If your primary focus is sealing in extreme chemical, temperature, or high-pressure environments: Choose PTFE, but be prepared to invest in precise groove measurement and specify an exact ring size.

- If your primary focus is a low-friction, dynamic seal: PTFE is the superior choice, with the critical requirement that the dimensions must be perfect to ensure both sealing and smooth movement.

Ultimately, mastering a material's limitations is the key to unlocking its unique performance advantages.

Summary Table:

| Feature | Rubber O-Rings | PTFE O-Rings |

|---|---|---|

| Material Type | Elastomer | Plastic (PTFE) |

| Elasticity | High (stretches easily) | Virtually none (rigid) |

| Sizing Tolerance | Forgiving (accommodates minor errors) | Critical (must be dimensionally perfect) |

| Primary Advantage | Ease of installation, cost-effectiveness | Chemical resistance, high-temperature performance, low friction |

| Risk of Improper Sizing | Minor leaks, reduced seal life | Guaranteed seal failure, potential damage |

| Common Solution for Non-Standard Sizes | Use nearest standard size | Often requires custom machining |

Need a Perfectly Sized PTFE Seal for Your Demanding Application?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including custom O-rings, seals, liners, and labware. We understand that for semiconductor, medical, laboratory, and industrial applications, 'close enough' isn't acceptable.

We provide the exact dimensional precision your high-performance systems require.

Our value to you:

- Custom Fabrication: We expertly machine PTFE O-rings to your exact specifications, from prototypes to high-volume production runs.

- Material Expertise: Leverage our deep knowledge of PTFE's properties to solve your toughest sealing challenges involving extreme chemicals, temperatures, or pressures.

- Guaranteed Fit and Function: Eliminate the risk of seal failure by partnering with a manufacturer that prioritizes precision above all else.

Don't let sizing challenges compromise your project's integrity. Contact KINTEK today to discuss your custom PTFE component needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments