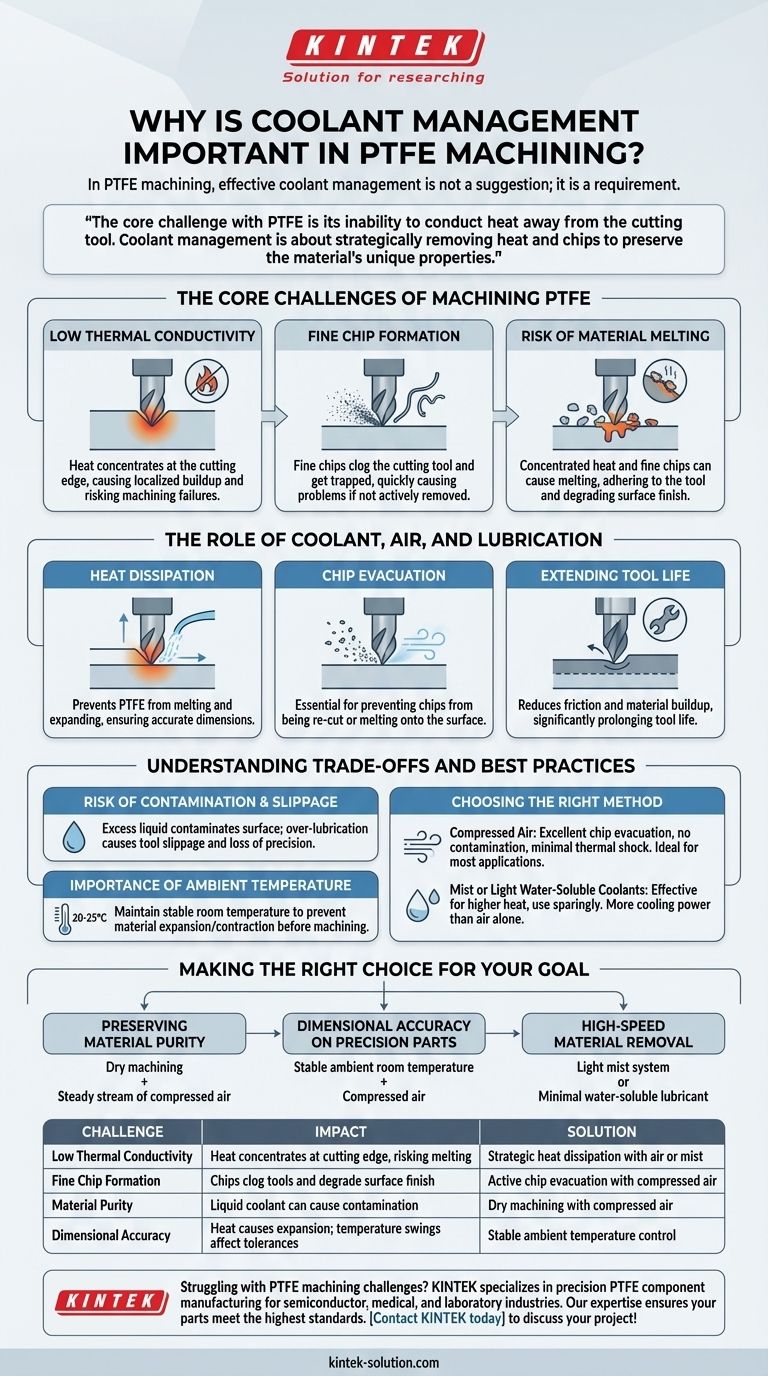

In PTFE machining, effective coolant management is not a suggestion; it is a requirement. It serves the dual purpose of dissipating heat to prevent the material from melting and clearing away fine chips to protect the surface finish. Proper management is the key to maintaining the dimensional accuracy and structural integrity of the final component.

The core challenge with PTFE is its inability to conduct heat away from the cutting tool. Therefore, coolant management isn't about flooding the part like with metals, but about strategically removing heat and chips with minimal intervention to preserve the material's unique properties.

The Core Challenges of Machining PTFE

Polytetrafluoroethylene (PTFE) behaves very differently from metals during machining. Understanding its unique characteristics is the first step toward successful outcomes.

Low Thermal Conductivity

PTFE is an excellent thermal insulator. This means that heat generated at the cutting edge does not dissipate through the material but instead concentrates right where the tool meets the part.

This localized heat buildup is the primary cause of most machining failures.

Fine Chip Formation

Unlike metals that often produce clean, manageable chips, PTFE generates fine, powdery, or stringy chips. These small particles do not easily fall away from the cutting area.

If not actively removed, these chips can clog the cutting tool, get trapped between the tool and the workpiece, and quickly cause problems.

Risk of Material Melting

When the concentrated heat from low thermal conductivity combines with the fine chips, the chips can easily melt.

This melted material will adhere to the cutting tool and degrade the surface of the component, resulting in a poor finish and a loss of dimensional accuracy.

The Role of Coolant, Air, and Lubrication

The term "coolant" in PTFE machining often refers to more than just traditional liquid coolants. The goal is to address the core challenges of heat and chip control.

Primary Function: Heat Dissipation

The first and most critical job is to remove heat from the cutting zone. This prevents the PTFE from reaching its melting point and undergoing thermal expansion.

By keeping the material thermally stable, you ensure that the dimensions of the finished part are accurate and consistent.

Secondary Function: Chip Evacuation

A stream of compressed air or a light mist of coolant physically blows the fine PTFE chips away from the cutting edge.

This process, known as chip evacuation, is essential for preventing chips from being re-cut or melting onto the surface, which is a direct cause of poor surface finish.

Extending Tool Life

By reducing friction and preventing melted material from building up on the cutting edge, proper coolant and lubrication can significantly prolong the life of your tooling.

Understanding the Trade-offs and Best Practices

More is not better when it comes to coolant for PTFE. The strategy must be precise and intentional.

The Risk of Contamination and Slippage

Using too much liquid coolant can contaminate the surface of the PTFE. While the material is non-porous, surface purity can be critical for certain applications.

Over-lubrication, especially with dry lubricants, can also cause tool slippage, leading to a loss of control and precision. The key is to use these aids sparingly.

Choosing the Right Method

The best method depends on the specific machining operation.

- Compressed Air: Often the ideal choice. It provides excellent chip evacuation with zero risk of chemical contamination and minimal thermal shock.

- Mist or Light Water-Soluble Coolants: These are effective for more aggressive cuts where heat generation is higher. They offer more cooling power than air alone but must be used sparingly.

The Importance of Ambient Temperature

Coolant management extends to the entire environment. Maintaining a stable room temperature between 20–25°C (68–77°F) is critical.

This prevents the raw material from expanding or contracting before machining even begins, which is especially important for components with thin walls or tight tolerances.

Making the Right Choice for Your Goal

Your approach to coolant and environmental control should be dictated by the desired outcome for the component.

- If your primary focus is preserving material purity: Use dry machining with a steady stream of compressed air for chip evacuation.

- If your primary focus is dimensional accuracy on a precision part: Prioritize a stable ambient room temperature and use compressed air to avoid the thermal shock of a liquid coolant.

- If your primary focus is high-speed material removal: Employ a light mist system or a minimal amount of water-soluble lubricant to manage the higher heat load effectively.

Mastering these environmental controls is fundamental to machining PTFE successfully and repeatably.

Summary Table:

| Challenge | Impact | Solution |

|---|---|---|

| Low Thermal Conductivity | Heat concentrates at cutting edge, risking melting | Strategic heat dissipation with air or mist |

| Fine Chip Formation | Chips clog tools and degrade surface finish | Active chip evacuation with compressed air |

| Material Purity | Liquid coolant can cause contamination | Dry machining with compressed air |

| Dimensional Accuracy | Heat causes expansion; temperature swings affect tolerances | Stable ambient temperature control |

Struggling with PTFE machining challenges? KINTEK specializes in precision PTFE component manufacturing for the semiconductor, medical, and laboratory industries. Our expertise in managing coolant, heat, and chip evacuation ensures your parts meet the highest standards for dimensional accuracy and surface finish. Whether you need custom prototypes or high-volume production, we deliver reliable results.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials