In short, PTFE washers are used for sealing because they possess an elite combination of properties that few other materials can match. They are almost completely immune to chemical attack, remain stable and flexible across an enormous temperature range, and have an extremely low coefficient offriction, making them ideal for creating durable, reliable seals in the most demanding environments.

The core reason for PTFE's dominance in sealing isn't just one superior property, but its unique ability to deliver chemical, thermal, and mechanical stability all at once. This makes it a "problem-solver" material for applications where conventional elastomers or plastics would quickly degrade and fail.

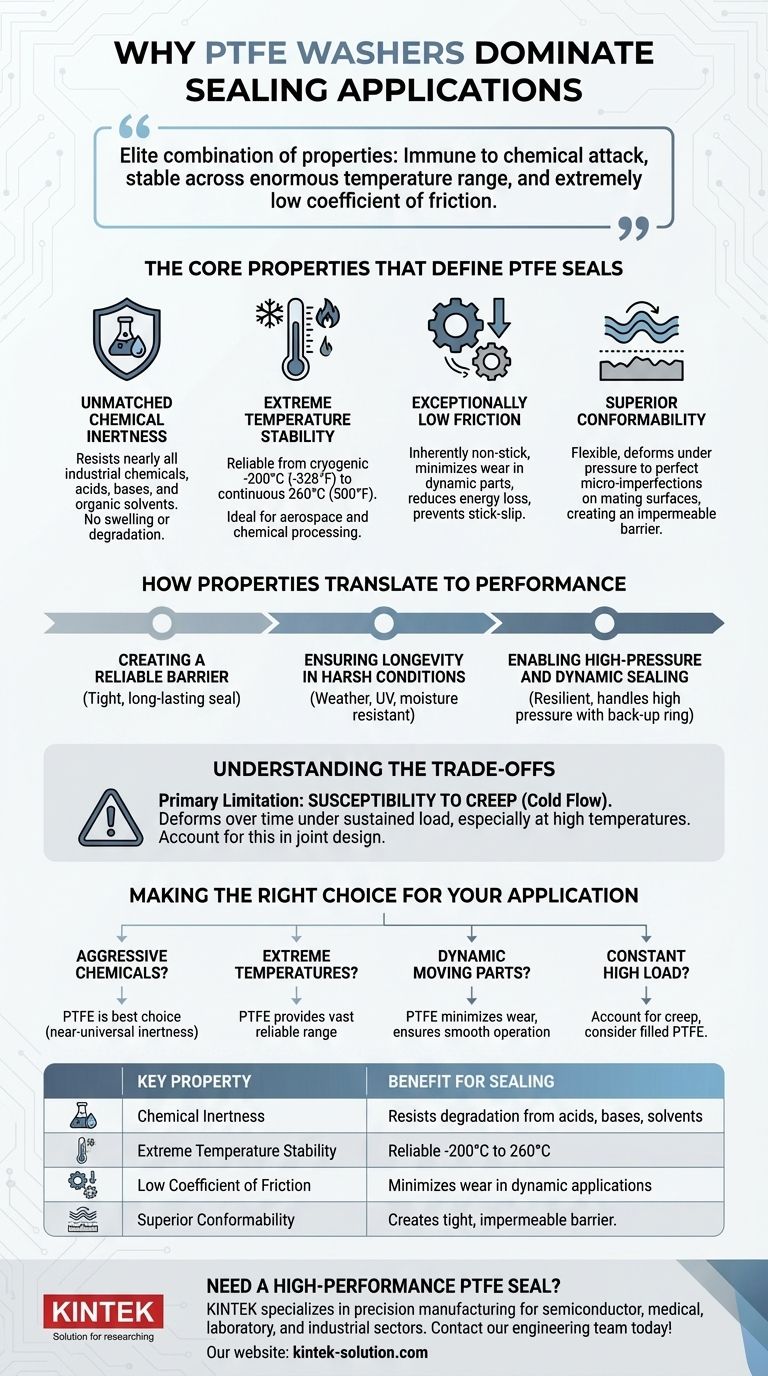

The Core Properties That Define PTFE Seals

To understand why PTFE (polytetrafluoroethylene) is so effective, we must look at the specific characteristics that directly contribute to its sealing performance.

Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials known. It remains completely unaffected by the vast majority of industrial chemicals, including aggressive acids, bases, and organic solvents.

This inertness ensures that the washer will not swell, soften, or degrade when exposed to corrosive fluids, maintaining the integrity of the seal over its entire service life.

Extreme Temperature Stability

PTFE washers perform reliably across an exceptionally wide temperature spectrum, typically from cryogenic lows of -200°C (-328°F) up to continuous service temperatures of 260°C (500°F).

This allows them to be used in applications ranging from aerospace to chemical processing, where temperature fluctuations are common and would cause other materials to become brittle or melt.

Exceptionally Low Friction

With one of the lowest coefficients of friction of any solid material, PTFE is inherently non-stick.

In dynamic sealing applications where parts are moving against the washer, this property is critical. It minimizes wear and tear on both the seal and the moving components, reduces operational energy loss, and prevents stick-slip issues.

Superior Conformability

PTFE is a relatively soft and flexible material. This allows it to deform under pressure and conform perfectly to the microscopic imperfections and irregularities on mating surfaces.

This ability to "flow" into gaps is the fundamental requirement of any gasket or seal, as it creates an impermeable barrier that prevents liquids or gases from escaping.

How These Properties Translate to Performance

These individual properties combine to deliver tangible benefits in real-world sealing applications.

Creating a Reliable Barrier

The combination of chemical inertness and conformability means a PTFE washer creates a tight, long-lasting barrier against moisture and contaminants. The seal remains intact because the material itself won't be compromised by the substance it is sealing.

Ensuring Longevity in Harsh Conditions

PTFE's excellent resistance to weathering, UV radiation, moisture, and oxygen means it does not become brittle or degrade over time, even in harsh outdoor or industrial settings. This contributes directly to assembly reliability and reduces maintenance needs.

Enabling High-Pressure and Dynamic Sealing

While soft, PTFE's resilience allows it to handle high pressures, especially when paired with a stronger back-up ring (often made of PEEK). Its low friction and high wear resistance make it a premier choice for seals in rotating or reciprocating systems.

Understanding the Trade-offs

No material is perfect. To use PTFE effectively, it's critical to be aware of its primary limitation.

Susceptibility to Creep (Cold Flow)

The primary trade-off for PTFE's excellent conformability is its tendency to creep, or "cold flow."

Under a constant, sustained compressive load (like a tightened bolt), the material can slowly deform over time, potentially reducing the sealing pressure. This effect is more pronounced at elevated temperatures. Engineers must account for this behavior in joint design, especially in high-load applications.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE washer is the optimal solution for your specific goal.

- If your primary focus is sealing aggressive chemicals: PTFE is almost certainly your best choice due to its near-universal chemical inertness.

- If your application involves extreme temperature fluctuations: PTFE's vast service range from cryogenic to high heat makes it a uniquely reliable option.

- If you are designing a dynamic seal with moving parts: PTFE's extremely low coefficient of friction will minimize wear, prevent sticking, and ensure smooth operation.

- If your seal is under a constant, high mechanical load: You must account for PTFE's tendency to creep and may need to consider filled PTFE grades for improved stability.

Ultimately, understanding both the exceptional strengths and the specific limitations of PTFE is the key to engineering a reliable and long-lasting seal.

Summary Table:

| Key Property | Benefit for Sealing |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents; prevents degradation. |

| Extreme Temperature Stability | Performs reliably from -200°C to 260°C (-328°F to 500°F). |

| Low Coefficient of Friction | Minimizes wear in dynamic applications; reduces operational energy loss. |

| Superior Conformability | Deforms under pressure to create a tight, impermeable barrier. |

Need a High-Performance PTFE Seal for Your Application?

KINTEK specializes in the precision manufacturing of PTFE components, including seals, washers, and custom fabrications. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions that combine chemical resistance, thermal stability, and mechanical reliability.

Whether you require a prototype or high-volume production, our expertise ensures your sealing application performs flawlessly in the most demanding environments.

Contact our engineering team today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support