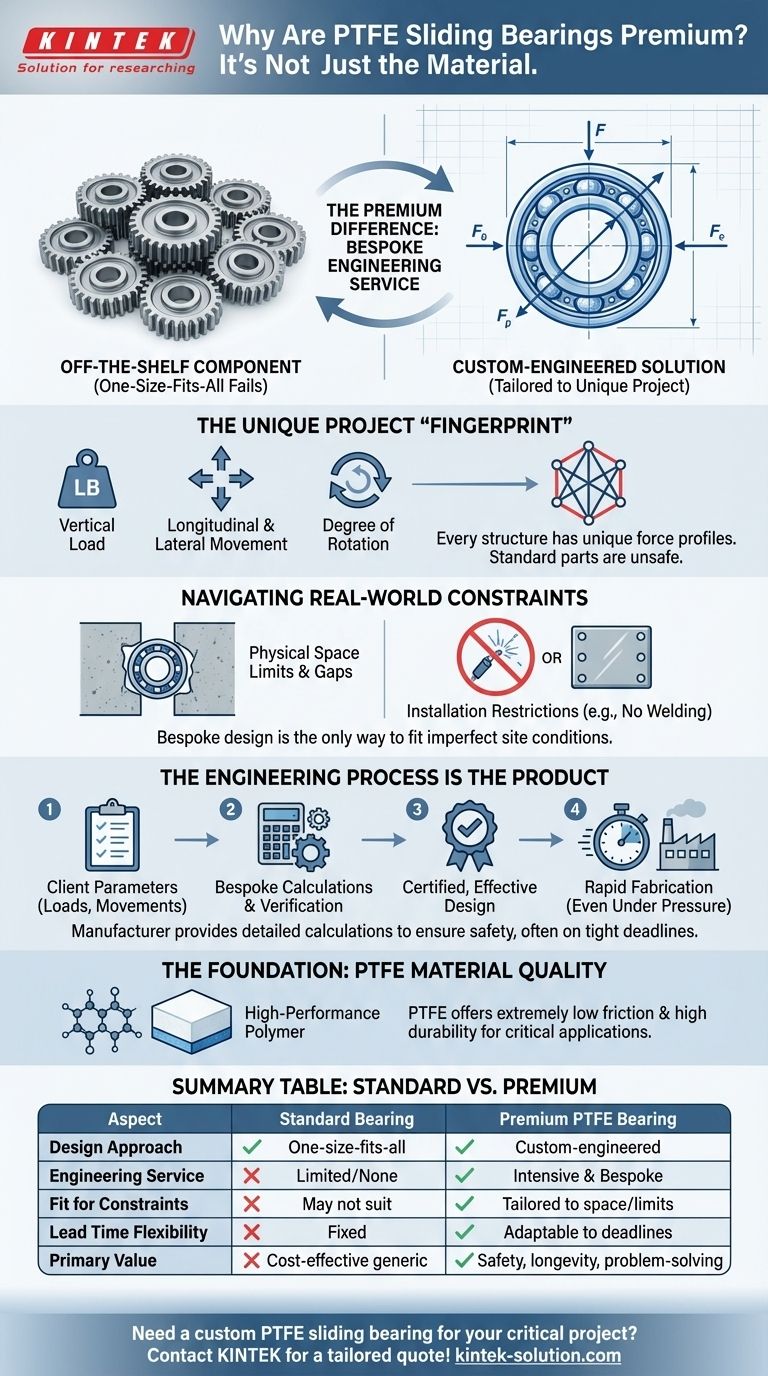

In short, PTFE sliding bearings are considered premium products because they are not off-the-shelf components. Instead, they are custom-engineered solutions, specifically designed and calculated to meet the unique structural loads, movements, and physical constraints of a single, specific project.

The "premium" label refers less to the raw material and more to the intensive, bespoke engineering service required. Each bearing is a unique solution tailored to complex project demands, often under significant time pressure.

Why a "One-Size-Fits-All" Bearing Fails

The core function of a sliding bearing is to manage the transfer of loads and accommodate movement between structural elements. In large-scale projects like bridges, buildings, or industrial equipment, these forces are never generic.

The Unique "Fingerprint" of Each Project

Every structure has a unique profile of forces. A manufacturer cannot design an effective bearing without knowing the precise parameters it must handle.

These specifications often include vertical load, anticipated longitudinal and lateral movement, potential uplift loads, and the degree of rotation. These factors are dictated by the structure's design and environment, making a standardized part unfeasible and unsafe.

The Engineering is Part of the Product

The manufacturer's role extends beyond simple fabrication. They must take the client's parameters and design a bearing capable of accommodating them.

This process involves providing detailed calculations based on material properties to verify that the proposed custom design is not just possible, but certifiably effective and safe for the intended application.

Navigating Real-World Project Constraints

The need for customization is intensified by the physical and logistical challenges inherent in complex construction projects. A bearing must not only handle theoretical loads but also fit perfectly within the actual, often imperfect, site conditions.

The Challenge of Physical Space

Engineers frequently face constraints like a limited size for the portal plate or pre-existing gaps between the substructure and superstructure. These physical limitations immediately rule out standard components and demand a bespoke design.

Restrictions on Installation

The project may also impose restrictions on how the bearing can be installed. Prohibitions on welding to certain surfaces or limitations on bolting patterns require the bearing's housing and anchorages to be custom-designed for a perfect fit.

The "Afterthought" Problem

In many projects, bearings are one of the last components to be considered. This creates a high-pressure scenario where a custom solution must be designed, verified, and manufactured with minimal lead time.

The ability to deliver this rapid, specialized engineering service is a key reason these products are positioned as premium.

The Foundation of Material Quality

While the custom engineering process is the primary driver of the "premium" label, the inherent quality of the material itself is the foundation of the bearing's performance.

PTFE: A High-Performance Polymer

Polytetrafluoroethylene (PTFE) is widely regarded as a superior fluoroplastic. Its unique properties make it indispensable in demanding industries like aerospace, medical, and mechanical engineering.

This high-performance material ensures the bearing can deliver extremely low friction and high durability, justifying its use in critical structural applications where failure is not an option.

Translating "Premium" into Project Value

Understanding why these bearings are premium helps you align their benefits with your project's specific goals. The value is found in the assurance of a tailored, verified solution.

- If your primary focus is safety and longevity: The custom engineering process ensures your bearing is designed precisely for the unique loads and movements of your structure, guaranteeing long-term performance.

- If your primary focus is navigating difficult site constraints: A bespoke design is often the only way to create a functional bearing that fits within the limited space or meets specific installation requirements.

- If your primary focus is solving a late-stage design challenge: The premium service includes the rapid, expert engineering needed to deliver a reliable component under a tight project deadline.

Ultimately, a PTFE sliding bearing's premium status reflects the delivery of a precisely engineered solution, not just a manufactured part.

Summary Table:

| Aspect | Standard Bearing | Premium PTFE Bearing |

|---|---|---|

| Design Approach | One-size-fits-all | Custom-engineered for specific project loads |

| Engineering Service | Limited or none | Intensive, bespoke calculations and verification |

| Fit for Constraints | May not suit unique site conditions | Tailored to physical space and installation limits |

| Lead Time Flexibility | Fixed | Adaptable to tight project deadlines |

| Primary Value | Cost-effective for generic uses | Safety, longevity, and problem-solving for critical applications |

Need a custom PTFE sliding bearing for your critical project?

At KINTEK, we specialize in precision-engineered PTFE components, including custom sliding bearings for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in bespoke fabrication—from prototypes to high-volume orders—ensures your bearing is designed to handle unique structural loads, movements, and site constraints. Let us deliver a solution that guarantees safety and performance.

Contact us today for a tailored quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments