At their core, PTFE slide bearings are considered maintenance-free because their key material, Polytetrafluoroethylene, is inherently self-lubricating. This unique characteristic eliminates the need for the external greases or oils that are mandatory for traditional mechanical bearings. Combined with its high resistance to contaminants and chemicals, this property removes the most common reasons for routine maintenance: lubrication, cleaning, and inspection.

The "maintenance-free" nature of PTFE bearings isn't an added feature; it is a fundamental property of the material itself. Unlike systems that require ongoing lubrication to function, PTFE bearings operate reliably because their low-friction surface is an intrinsic part of their design.

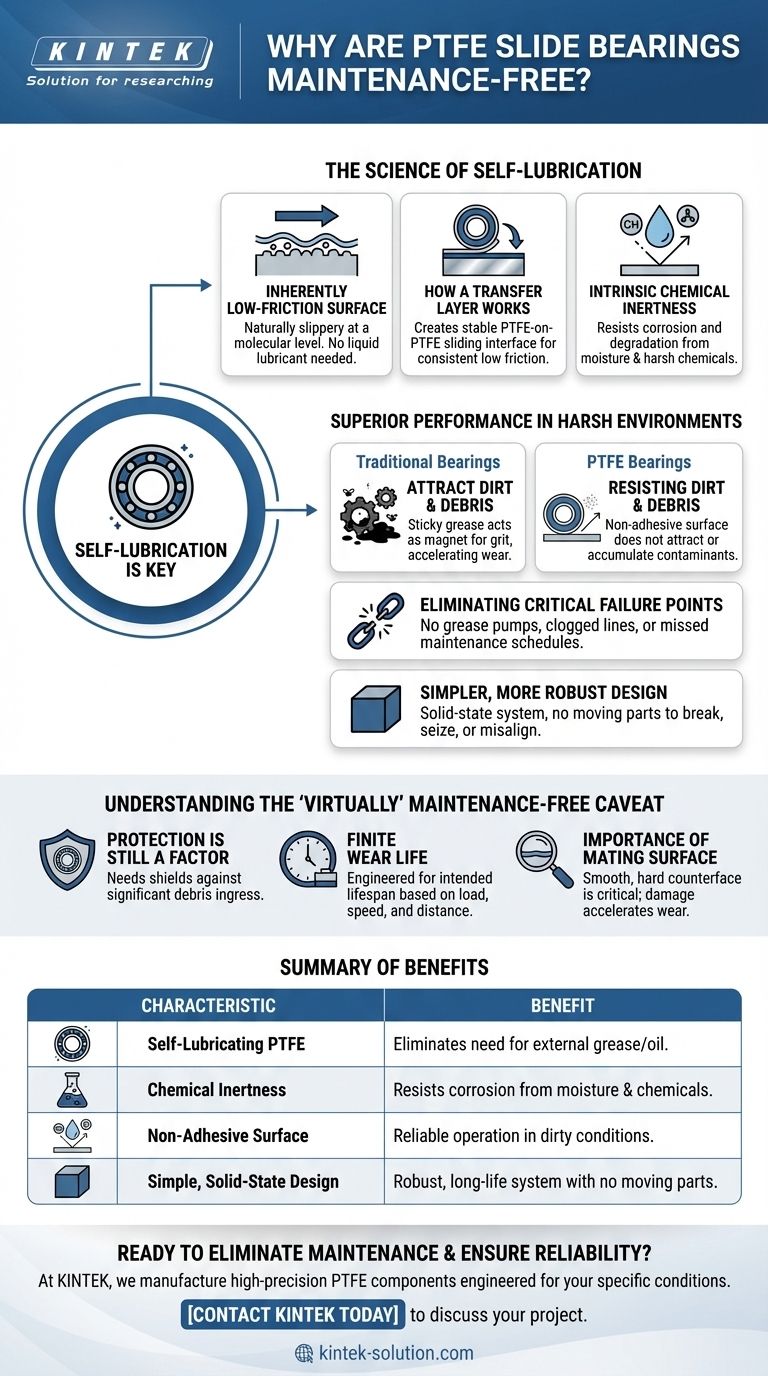

The Science of Self-Lubrication

To trust the "maintenance-free" claim, it's essential to understand the material science that makes it possible. The reliability of PTFE is not based on a coating or treatment but on its fundamental molecular structure.

An Inherently Low-Friction Surface

Polytetrafluoroethylene (PTFE) has one of the lowest coefficients of friction of any known solid material. This means it is naturally "slippery" at a microscopic level.

This property ensures that movement can occur with minimal resistance without the need for a liquid lubricant layer between the sliding surfaces.

How a Transfer Layer Works

During the initial movements under load, an imperceptibly thin layer of PTFE transfers from the bearing pad to the mating surface (typically polished stainless steel).

This process creates an ideal PTFE-on-PTFE sliding interface. This transfer layer is stable and self-sustaining, ensuring consistent low friction throughout the bearing's design life.

Intrinsic Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, solvents, and atmospheric conditions. It does not corrode or degrade from exposure to moisture or harsh substances.

This prevents the material breakdown and corrosion that plague metal bearings, which would otherwise necessitate protective coatings, seals, and regular inspections.

Superior Performance in Harsh Environments

The operational environment is often the biggest challenge for traditional bearings, but it's an area where PTFE excels. Its properties make it uniquely suited for conditions that would quickly cause other systems to fail.

Resisting Dirt and Debris

Traditional bearings rely on sticky grease or oil, which act as magnets for dust, dirt, and grit. This mixture creates an abrasive paste that dramatically accelerates wear and requires frequent, labor-intensive cleaning.

PTFE's surface is non-adhesive. While it can embed very small particles, it does not attract and accumulate debris. This means it continues to function reliably even in dusty or dirty conditions.

Eliminating a Critical Failure Point

The need for external lubrication is the primary source of maintenance and a common point of failure in mechanical systems.

By eliminating this requirement, PTFE bearings remove the risk of failed grease pumps, clogged lubricant lines, or human error associated with missed maintenance schedules.

A Simpler, More Robust Design

Traditional rollers and rocker arm supports involve multiple moving parts. These components can seize, misalign, or corrode, requiring complex and costly inspection and repair.

A PTFE slide bearing is a simple, solid-state system with no moving parts to break or misalign, making it inherently more robust and reliable over its lifespan.

Understanding the "Virtually" Maintenance-Free Caveat

While PTFE bearings are exceptionally low-maintenance, no component is entirely immune to its operating conditions. Understanding their limitations is key to proper design and ensuring long-term performance.

Protection Is Still a Factor

The claim is "virtually" maintenance-free. As the references note, the bearings still require protection against significant ingress of large, sharp debris.

This is typically handled during the structural design phase, with simple shields or housings that prevent large objects from damaging the sliding surfaces.

Finite Wear Life

PTFE is not indestructible. The material has a finite wear life that is determined by the specific load, sliding speed, and total distance traveled over its lifetime.

Proper engineering involves selecting a PTFE compound and thickness sufficient to last the intended service life of the structure. The "maintenance" is effectively front-loaded into the initial design calculations.

The Importance of the Mating Surface

The performance of the PTFE pad is critically dependent on the hard, smooth surface it slides against.

Scratches, gouges, or corrosion on the mating steel plate can act like a file, dramatically accelerating wear on the PTFE. While the bearing itself doesn't need maintenance, ensuring the mating surface is protected is essential.

How to Apply This to Your Project

Choosing a bearing system requires matching its properties to your project's specific demands, environment, and long-term goals.

- If your primary focus is longevity in a clean, predictable environment: A well-designed PTFE system is a true "set and forget" solution, as its predictable and minimal wear rate will be maximized.

- If your primary focus is reliability in a dirty or corrosive environment: PTFE is superior to lubricated systems because it doesn't attract abrasive contaminants or require specialized, chemical-resistant grease.

- If your primary focus is minimizing long-term operational costs: The complete elimination of lubrication schedules, inspections, and labor makes PTFE a highly cost-effective choice over the project's entire lifecycle.

Ultimately, trusting a PTFE bearing comes from understanding that its reliability is engineered into the material itself, not dependent on external upkeep.

Summary Table:

| Key Characteristic | Benefit |

|---|---|

| Self-Lubricating PTFE | Eliminates need for external grease or oil, removing a primary failure point. |

| Chemical Inertness | Resists corrosion from moisture and harsh chemicals, preventing degradation. |

| Non-Adhesive Surface | Does not attract dirt and debris, ensuring reliable operation in dirty conditions. |

| Simple, Solid-State Design | No moving parts to seize or misalign, resulting in a robust, long-life system. |

Ready to eliminate maintenance and ensure long-term reliability in your application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom slide bearings, seals, liners, and labware. Our expertise ensures your bearings are engineered for your specific load, speed, and environmental conditions—maximizing performance and lifespan.

Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, we deliver the precision and reliability you require.

Contact KINTEK today to discuss your project and discover how our PTFE solutions can work for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials