In short, PTFE oil seals are a solution for 'forbidden sealing areas' because their fundamental material properties allow them to function where traditional seals cannot. Environments with aggressive chemicals, extreme temperatures, or a lack of lubrication will destroy conventional elastomer seals, but PTFE’s chemical inertness, thermal stability, and self-lubricating nature allow it to perform reliably in these exact conditions.

The core reason PTFE seals succeed in "forbidden" applications is that they are not just a different type of rubber; they are a completely different class of material. Their value lies in providing a robust, reliable seal in environments that are fundamentally hostile to conventional materials.

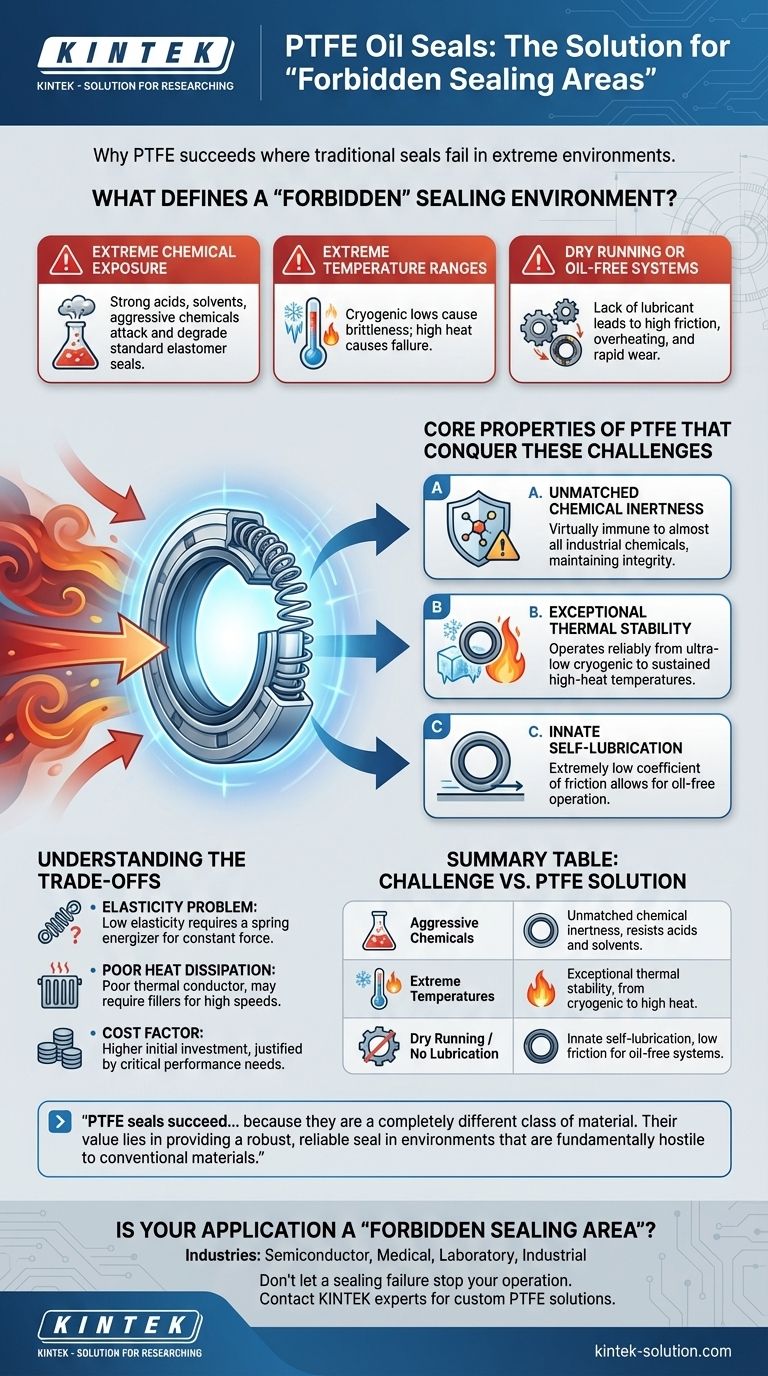

What Defines a 'Forbidden' Sealing Environment?

These are operating conditions so severe that they are "off-limits" or "forbidden" for standard sealing materials like nitrile or viton rubber. Failure in these areas is not a matter of if, but when.

Extreme Chemical Exposure

Many industrial processes involve strong acids, solvents, or aggressive chemicals. These substances will chemically attack and rapidly degrade standard elastomer seals, causing them to swell, harden, or dissolve.

Extreme Temperature Ranges

Applications can range from cryogenic lows to incredibly high heat. Conventional seals become brittle and crack at low temperatures or lose their structural integrity and fail at high temperatures.

Dry Running or Oil-Free Systems

Traditional oil seals rely on a thin film of lubricant to reduce friction and wear. In systems that run dry or without oil, a standard seal will overheat and wear out almost instantly due to high friction.

The Core Properties of PTFE That Conquer These Challenges

PTFE (Polytetrafluoroethylene) is an engineered polymer with a unique combination of properties that directly counter the challenges of forbidden sealing areas.

Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually immune to attack from almost all industrial chemicals and solvents, ensuring it maintains its integrity and sealing force.

Exceptional Thermal Stability

PTFE seals can operate across a vast temperature spectrum, from ultra-low cryogenic temperatures to sustained high-heat environments. This stability prevents the material from becoming brittle or degrading.

Innate Self-Lubrication

PTFE has an extremely low coefficient of friction, one of the lowest of any solid material. This allows it to run with very little friction, even in completely dry, oil-free applications where other seals would fail from heat and wear.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. Understanding its limitations is key to using it effectively.

The Elasticity Problem

Unlike rubber, PTFE has very low elasticity and does not "bounce back" into shape. To compensate, most PTFE seals incorporate a metal spring energizer that provides the constant outward force needed to maintain a tight seal.

Poor Heat Dissipation

PTFE is a poor thermal conductor, meaning it doesn't dissipate heat well. In very high-speed applications, this can be a problem, though modern seals often use fillers like copper or graphene to improve thermal conductivity.

The Cost Factor

PTFE seals are more expensive than their conventional counterparts. Their use is justified by the extreme performance requirements and the high cost of failure in a critical application.

Making the Right Choice for Your Application

Selecting the correct seal is a matter of matching the material to the operational reality of the environment.

- If your primary focus is withstanding aggressive chemicals or extreme temperatures: PTFE is not just an option, it is often the only viable solution.

- If your application involves dry running or requires minimal lubrication: PTFE's self-lubricating properties are critical for preventing premature failure and ensuring a long service life.

- If your application has a standard operating environment and cost is a primary driver: A conventional oil seal remains the most cost-effective and reliable choice for the vast majority of common uses.

By understanding these fundamental differences, you can engineer for maximum reliability by choosing the seal that meets the true demands of the application.

Summary Table:

| Challenge (Forbidden Area) | PTFE Seal Solution |

|---|---|

| Aggressive Chemicals | Unmatched chemical inertness, resists acids and solvents. |

| Extreme Temperatures | Exceptional thermal stability, from cryogenic to high heat. |

| Dry Running / No Lubrication | Innate self-lubrication, low friction for oil-free systems. |

Is Your Application a 'Forbidden Sealing Area'?

If your semiconductor, medical, laboratory, or industrial equipment faces aggressive chemicals, extreme temperatures, or runs without lubrication, standard seals are a liability. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—engineered to perform reliably in these exact conditions.

We provide custom fabrication from prototypes to high-volume orders, ensuring you get a seal that matches the true demands of your application.

Don't let a sealing failure stop your operation. Contact our experts today to discuss a robust PTFE sealing solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials