In short, PTFE oil scraper rings are considered indispensable because they uniquely combine three properties crucial for modern air compressors: extreme heat resistance, near-zero chemical reactivity, and a very low coefficient of friction. This combination allows them to effectively prevent oil contamination, reduce energy consumption, and ensure long-term reliability in demanding conditions where other materials would quickly fail.

The core function of an oil scraper ring is not just to scrape oil, but to maintain a precise balance between lubrication and purity. PTFE's unique material properties make it the superior choice for achieving this balance, directly enabling the high-efficiency and oil-free operation demanded by modern industrial, medical, and high-pressure applications.

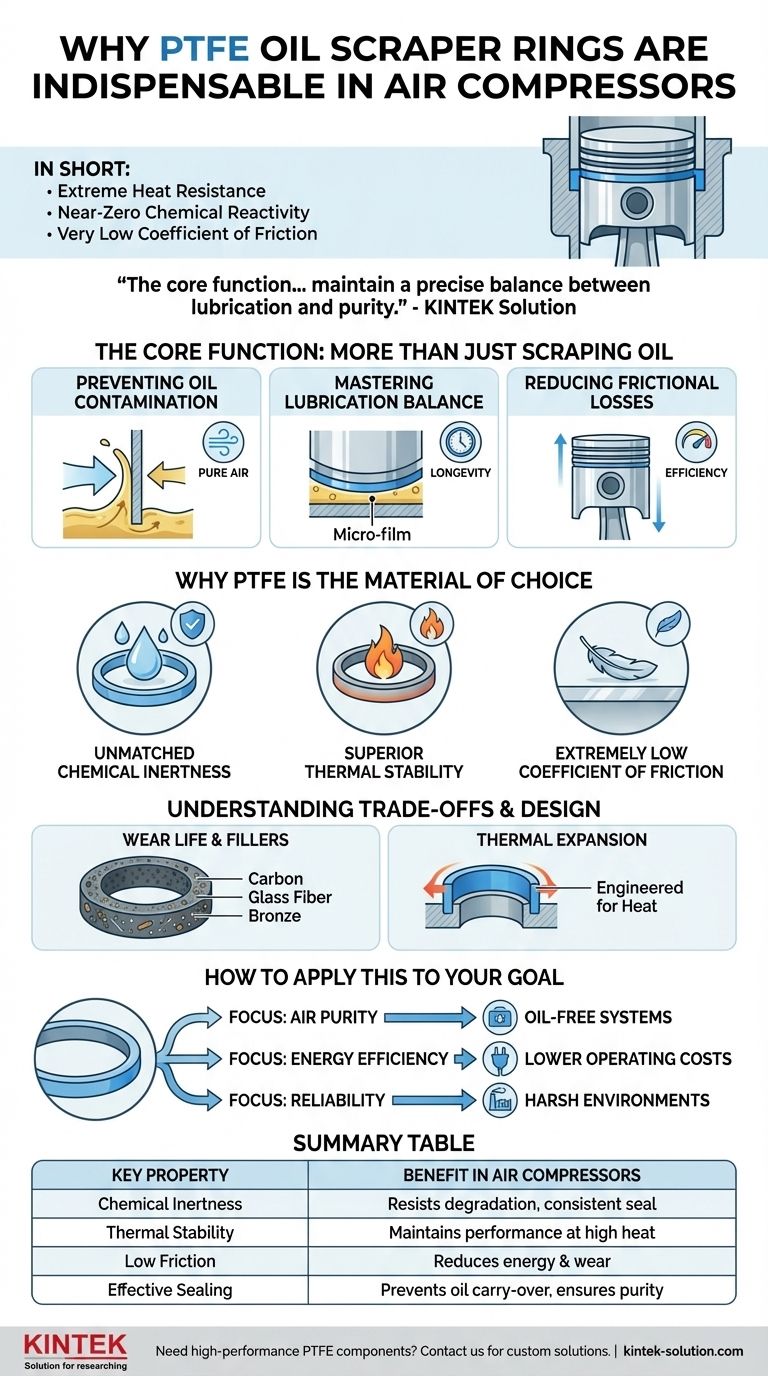

The Core Function: More Than Just Scraping Oil

A common misconception is that an oil scraper ring simply wipes oil off the cylinder wall. Its true role is far more nuanced and critical to the compressor's health and performance.

The Primary Mandate: Preventing Oil Contamination

The most vital job of the scraper ring is to prevent crankcase oil from entering the compression chamber.

Oil in the compressed air stream is a major problem. It can contaminate end products (like food or electronics), foul downstream equipment, and, in high-pressure systems, create a safety risk of auto-ignition (dieseling).

PTFE rings create a highly effective seal that scrapes excess oil back down into the crankcase, ensuring the air remains pure.

Mastering the Lubrication Balance

While preventing bulk oil transfer, the ring must also allow a microscopic oil film to remain on the cylinder wall.

This micro-film is essential for lubricating the piston and compression rings, preventing metal-on-metal contact, and minimizing wear. A ring that is too aggressive would cause premature failure.

PTFE's properties allow for ring designs that achieve this delicate balance, ensuring both purity and component longevity.

Reducing Frictional Losses

Every bit of friction in a compressor translates to wasted energy and unwanted heat.

Because PTFE is inherently "slippery" (self-lubricating), it glides over the cylinder wall with minimal resistance. This directly reduces the energy required to drive the piston, leading to higher overall efficiency and lower operating temperatures.

Why PTFE is the Material of Choice

Other materials can be used for rings, but PTFE (Polytetrafluoroethylene) offers a trifecta of benefits that makes it uniquely suited for the harsh environment inside a compressor.

Unmatched Chemical Inertness

Compressors often use advanced synthetic lubricants and may handle various process gases beyond simple air.

PTFE is one of the most chemically inert substances known. It will not degrade, swell, or soften when exposed to aggressive chemicals or oils, ensuring a consistent seal and long service life.

Superior Thermal Stability

The act of compressing gas generates significant heat. Ring materials must remain stable and effective at high operating temperatures.

PTFE maintains its integrity and mechanical properties at temperatures that would cause other polymers to fail, making it ideal for continuous-duty and high-pressure compressors.

Extremely Low Coefficient of Friction

This is PTFE's most famous characteristic. Its low friction is not dependent on the oil film alone; the material itself is slick.

This reduces wear on both the ring and the cylinder wall, extends the maintenance interval, and contributes significantly to energy savings over the life of the machine.

Understanding the Trade-offs and Design Considerations

While highly effective, PTFE is not a "magic" material. Its use requires specific engineering considerations to maximize its benefits.

Wear Life and Fillers

Pure PTFE can be relatively soft. To enhance its durability, stiffness, and wear resistance for demanding applications, it is often blended with fillers.

Common fillers include carbon, glass fiber, or bronze. These additives create a composite material that retains PTFE's core benefits while dramatically improving its mechanical strength and lifespan. The specific blend is chosen based on the compressor's operating pressure, speed, and gas type.

Thermal Expansion

Like all polymers, PTFE has a higher coefficient of thermal expansion than the metal components around it.

Engineers must account for this expansion in the design of the piston groove and the ring itself. Proper design ensures the ring maintains an effective seal whether the compressor is cold or at full operating temperature.

How to Apply This to Your Goal

When evaluating compressor technology or maintenance parts, your specific priority will determine the importance of PTFE rings.

- If your primary focus is air purity: PTFE rings are the enabling technology for oil-free and "Class 0" air systems, making them non-negotiable for food, beverage, medical, and electronics manufacturing.

- If your primary focus is energy efficiency: The low-friction nature of PTFE rings provides a measurable reduction in energy consumption, leading to lower operational costs over the compressor's lifespan.

- If your primary focus is reliability in harsh environments: For high-pressure systems or compressors handling corrosive gases, PTFE's chemical and thermal resistance is essential for ensuring long-term operational integrity.

Ultimately, specifying PTFE scraper rings is a strategic decision to protect your process, improve efficiency, and enhance the fundamental reliability of the compressed air system.

Summary Table:

| Key Property | Benefit in Air Compressors |

|---|---|

| Chemical Inertness | Resists degradation from oils and gases, ensuring a consistent seal. |

| Thermal Stability | Maintains performance at high temperatures for continuous-duty operation. |

| Low Friction | Reduces energy consumption and wear, extending component life. |

| Effective Sealing | Prevents oil carry-over, enabling oil-free air purity for sensitive applications. |

Need high-performance PTFE components for your critical applications?

At KINTEK, we specialize in manufacturing precision PTFE seals, rings, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment achieves the highest standards of purity, efficiency, and reliability.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific requirements.

Contact us today to discuss how our PTFE solutions can enhance your compressor performance and protect your process.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications