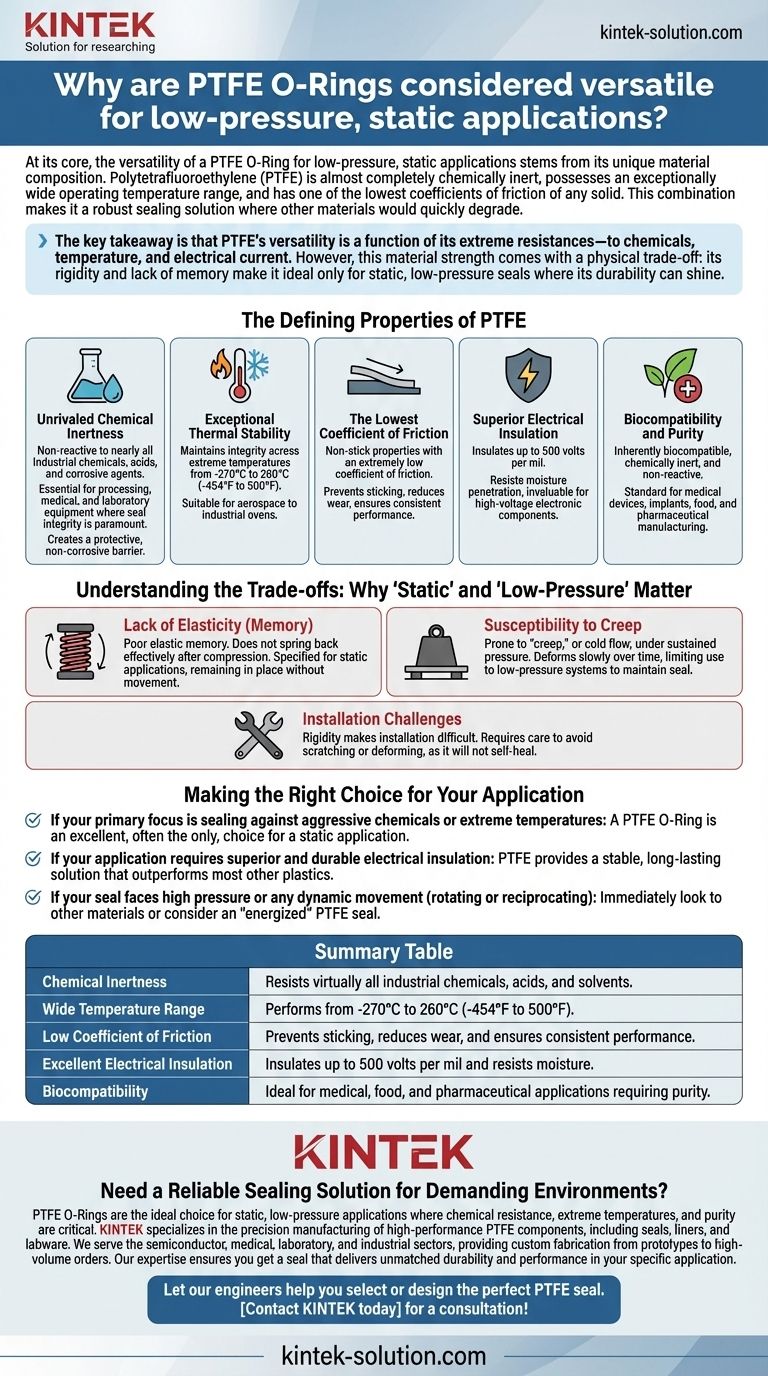

At its core, the versatility of a PTFE O-Ring for low-pressure, static applications stems from its unique material composition. Polytetrafluoroethylene (PTFE) is almost completely chemically inert, possesses an exceptionally wide operating temperature range, and has one of the lowest coefficients of friction of any solid. This combination makes it a robust sealing solution where other materials would quickly degrade.

The key takeaway is that PTFE's versatility is a function of its extreme resistances—to chemicals, temperature, and electrical current. However, this material strength comes with a physical trade-off: its rigidity and lack of memory make it ideal only for static, low-pressure seals where its durability can shine.

The Defining Properties of PTFE

To understand why PTFE is so versatile in its specific niche, we must break down its core characteristics. These properties are not just incrementally better than other polymers; in many cases, they are in a class of their own.

Unrivaled Chemical Inertness

PTFE is non-reactive to nearly all industrial chemicals, acids, and corrosive agents. This makes it an essential choice for processing, medical, and laboratory equipment where seal integrity cannot be compromised by aggressive media. Its composition creates a protective, non-corrosive barrier.

Exceptional Thermal Stability

The material maintains its integrity across an extreme temperature spectrum, from cryogenic lows of -270°C up to highs of 260°C (-454°F to 500°F). This allows PTFE O-Rings to be used in applications ranging from aerospace to industrial ovens without degrading.

The Lowest Coefficient of Friction

Known for its non-stick properties, PTFE has an extremely low coefficient of friction. In a sealing context, this prevents the O-ring from sticking to assembly components, reducing wear and ensuring consistent performance over its lifespan.

Superior Electrical Insulation

PTFE is one of the best known electrical insulators, capable of insulating up to 500 volts per mil. It resists moisture penetration far better than plastics like nylon or PVC, ensuring its insulating qualities do not diminish over time. This makes it invaluable for high-voltage electronic components and connectors.

Biocompatibility and Purity

Because it is chemically inert and non-reactive, PTFE is inherently biocompatible. This property makes it a standard material for medical devices, implants, and equipment used in food and pharmaceutical manufacturing where purity is non-negotiable.

Understanding the Trade-offs: Why 'Static' and 'Low-Pressure' Matter

The same molecular structure that gives PTFE its incredible resistance also creates its primary limitations. An objective assessment requires understanding what it cannot do.

Lack of Elasticity (Memory)

Unlike rubber elastomers (like Viton® or Buna-N), PTFE has very poor elastic memory. When compressed, it does not spring back to its original shape effectively. This is why it is specified for static applications, where the seal is compressed and remains in place without movement.

Susceptibility to Creep

Under sustained pressure (load), PTFE is prone to "creep," or cold flow, where the material slowly deforms over time. This is the reason for the low-pressure limitation. In high-pressure systems, a pure PTFE O-ring would eventually deform and compromise the seal.

Installation Challenges

The material's rigidity can make installation more difficult than with a flexible elastomer. Care must be taken to avoid scratching or deforming the O-ring during assembly, as it will not self-heal or rebound from damage.

Making the Right Choice for Your Application

Selecting the correct sealing material requires matching the material's profile to the application's demands.

- If your primary focus is sealing against aggressive chemicals or extreme temperatures: A PTFE O-Ring is an excellent, and often the only, choice for a static application.

- If your application requires superior and durable electrical insulation: PTFE provides a stable, long-lasting solution that outperforms most other plastics.

- If your seal faces high pressure or any dynamic movement (rotating or reciprocating): You should immediately look to other materials or consider an "energized" PTFE seal, which incorporates a spring to provide the necessary resilience.

Understanding these distinct properties empowers you to deploy PTFE O-Rings as a precise solution for your most demanding static sealing challenges.

Summary Table:

| Property | Benefit for Static, Low-Pressure Seals |

|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and solvents. |

| Wide Temperature Range | Performs from -270°C to 260°C (-454°F to 500°F). |

| Low Coefficient of Friction | Prevents sticking, reduces wear, and ensures consistent performance. |

| Excellent Electrical Insulation | Insulates up to 500 volts per mil and resists moisture. |

| Biocompatibility | Ideal for medical, food, and pharmaceutical applications requiring purity. |

Need a Reliable Sealing Solution for Demanding Environments?

PTFE O-Rings are the ideal choice for static, low-pressure applications where chemical resistance, extreme temperatures, and purity are critical. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including seals, liners, and labware.

We serve the semiconductor, medical, laboratory, and industrial sectors, providing custom fabrication from prototypes to high-volume orders. Our expertise ensures you get a seal that delivers unmatched durability and performance in your specific application.

Let our engineers help you select or design the perfect PTFE seal. Contact KINTEB today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers