In short, PTFE lip seals are uniquely suited for electric vehicles because they can withstand the extremely high rotational speeds and harsh operating conditions of an EV drivetrain. Traditional elastomer seals would rapidly fail under the combination of intense friction, high heat, and chemical exposure common in these applications.

Electric vehicles operate at shaft speeds far exceeding those of internal combustion engines, creating a point of failure for conventional seals. PTFE's fundamental properties—exceptionally low friction and high thermal stability—directly solve this high-speed challenge, ensuring reliability and efficiency.

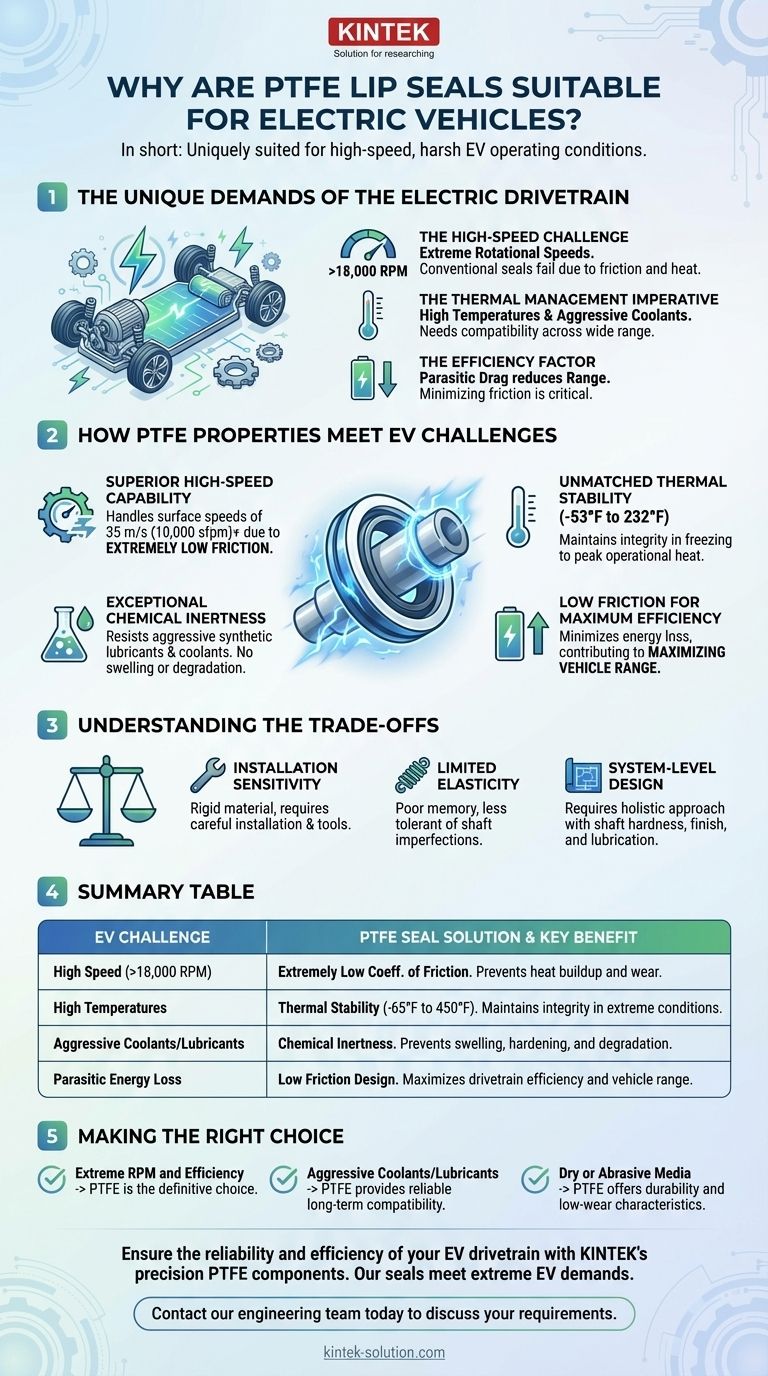

The Unique Demands of the Electric Drivetrain

To understand why PTFE is the material of choice, we must first recognize that an electric motor operates fundamentally differently from a gasoline engine. This creates a new set of engineering challenges for sealing components.

The High-Speed Challenge

Electric motors in modern EVs can easily exceed 18,000 RPM, a significant leap from the typical 4,000-6,000 RPM range of an internal combustion engine.

This high rotational velocity translates to extreme surface speeds at the seal lip. For a conventional rubber seal, this would generate immense friction and heat, leading to rapid material degradation, wear, and leakage.

The Thermal Management Imperative

EVs generate significant heat from the battery and motor, requiring aggressive liquid cooling systems. The seals used in these systems must not only withstand high temperatures but also be compatible with the specialized coolants and lubricants used.

These seals must maintain their integrity and performance across a wide operating temperature range, from cold starts to peak operational heat, without becoming brittle or soft.

The Efficiency Factor

In an electric vehicle, every watt of energy counts. Parasitic drag—energy loss from friction in moving parts—directly reduces the vehicle's range.

A high-friction seal can be a constant source of energy drain. Therefore, minimizing friction at all sealing points is a critical goal for maximizing drivetrain efficiency and battery life.

How PTFE Properties Meet EV Challenges

PTFE (Polytetrafluoroethylene) possesses a unique combination of material properties that directly addresses the challenges of high-speed electric drivetrains.

Superior High-Speed Capability

PTFE lip seals are engineered to handle surface speeds of 35 m/s (or 10,000 sfpm) and beyond.

This performance is a direct result of PTFE's extremely low coefficient of friction. The material is inherently slippery, allowing it to glide over the rotating shaft with minimal resistance, preventing the heat buildup and wear that would destroy other materials.

Unmatched Thermal Stability

PTFE maintains its structural integrity and sealing properties across an exceptionally wide temperature range, typically from -53°C to 232°C (-65°F to 450°F).

This ensures the seal performs reliably whether the vehicle is operating in freezing conditions or under the high thermal load of a performance run.

Exceptional Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including the aggressive synthetic lubricants and coolants used in EV battery packs and drive units.

This chemical resistance prevents the seal from swelling, hardening, or degrading over its lifespan, ensuring a long-term, leak-free connection.

Low Friction for Maximum Efficiency

The low-friction nature of PTFE not only enables high-speed operation but also minimizes parasitic energy loss.

By reducing drag on the motor's output shaft, PTFE seals contribute directly to the overall efficiency of the drivetrain, helping to maximize the vehicle's range.

Understanding the Trade-offs

While PTFE offers superior performance, it's important to understand its specific design considerations. It is not a universal drop-in replacement for all seal types.

Installation Sensitivity

PTFE is a more rigid material than traditional elastomers. The seal lip is less forgiving, and care must be taken during installation to avoid nicks or scratches that could compromise its function. Specialized installation tools are often required.

Limited Elasticity

Unlike rubber, PTFE has poor "memory" and does not rebound as effectively after being deformed. This means it is less tolerant of shaft imperfections like runout or surface irregularities. A high-quality shaft finish is critical for optimal seal performance.

System-Level Design

Achieving the full benefit of a PTFE seal requires a holistic design approach. Factors like shaft hardness, surface finish, and lubrication must be specified correctly to work in conjunction with the seal's properties.

Making the Right Choice for Your Application

Selecting the correct seal material is a critical engineering decision based on the specific demands of the application.

- If your primary focus is extreme RPM and efficiency: PTFE is the definitive choice for high-speed electric motor output shafts where traditional seals cannot survive.

- If your application involves aggressive coolants or lubricants: PTFE's chemical inertness provides the most reliable long-term performance and material compatibility.

- If your system requires sealing in dry or abrasive media: The durability and low-wear characteristics of PTFE make it a highly effective solution.

Ultimately, choosing PTFE is a strategic decision to ensure the long-term reliability and efficiency required by modern electric vehicle technology.

Summary Table:

| EV Challenge | PTFE Seal Solution | Key Benefit |

|---|---|---|

| High Speed (>18,000 RPM) | Extremely Low Coefficient of Friction | Prevents heat buildup and wear |

| High Temperatures | Thermal Stability (-65°F to 450°F) | Maintains integrity in extreme conditions |

| Aggressive Coolants/Lubricants | Chemical Inertness | Prevents swelling, hardening, and degradation |

| Parasitic Energy Loss | Low Friction Design | Maximizes drivetrain efficiency and vehicle range |

Ensure the reliability and efficiency of your electric vehicle drivetrain with KINTEK's precision PTFE components.

Our PTFE lip seals are engineered to meet the extreme demands of high-speed EV motors, aggressive thermal cycles, and harsh chemical environments. By minimizing friction and parasitic drag, our seals contribute directly to maximizing your vehicle's range and performance.

KINTEK specializes in custom fabricating high-performance PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We deliver precision from prototypes to high-volume production.

Contact our engineering team today to discuss your specific sealing requirements and discover how our PTFE solutions can enhance your EV application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications