In the world of demanding rotary applications, PTFE lip seals are a transformative technology because they fundamentally overcome the core limitations of traditional elastomeric seals. Where conventional seals fail due to high speeds, extreme temperatures, or aggressive chemicals, PTFE's unique material properties allow it to thrive, ensuring machinery runs more efficiently and reliably.

The critical advantage of a PTFE lip seal isn't just that it's "better" — it's that it operates on a different principle. Instead of relying on rubber-like elasticity, it leverages an exceptionally low-friction, chemically inert material to provide a stable, long-lasting seal in conditions that would quickly destroy conventional alternatives.

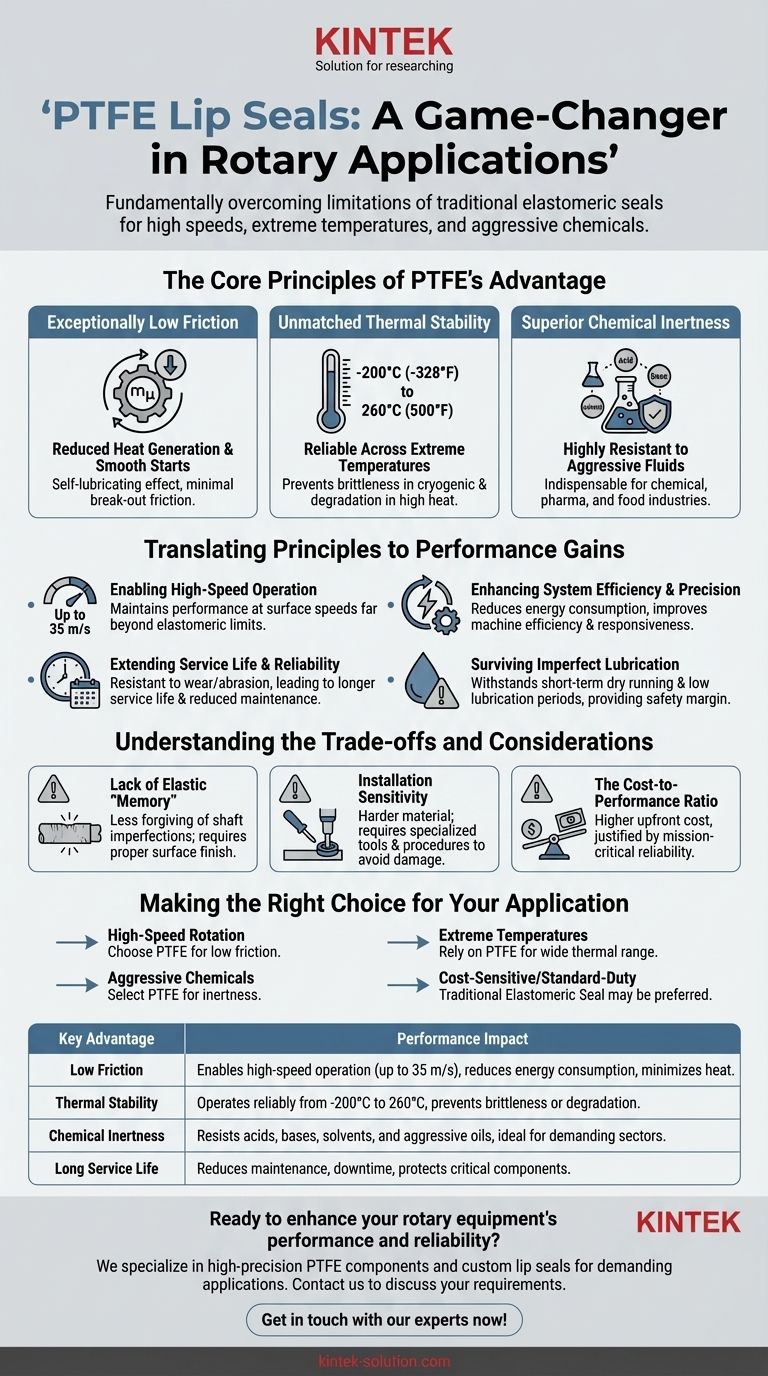

The Core Principles of PTFE's Advantage

To understand why PTFE (Polytetrafluoroethylene) is so effective, we must look at its fundamental material characteristics. These properties are not just incremental improvements; they represent a different approach to sealing.

Exceptionally Low Friction

The defining feature of PTFE is its remarkably low coefficient of friction, which is one of the lowest of any solid material. This creates a self-lubricating effect at the sealing point.

This characteristic directly translates to reduced heat generation, even at very high rotational speeds. It also means minimal "break-out" friction, allowing machinery to start smoothly after long periods of downtime without the seal sticking to the shaft.

Unmatched Thermal Stability

PTFE lip seals operate reliably across an enormous temperature range, typically from -200°C (-328°F) to 260°C (500°F).

This stability prevents the material from becoming brittle in cryogenic applications or degrading in high-heat environments—common failure points for standard rubber or nitrile seals.

Superior Chemical Inertness

PTFE is almost entirely inert, meaning it is highly resistant to acids, bases, solvents, and aggressive oils.

This makes it an indispensable solution in industries like chemical processing, pharmaceuticals, and food production, where the seal must maintain its integrity when exposed to corrosive or reactive media.

How These Principles Translate to Performance Gains

The unique properties of PTFE are not just theoretical advantages. They deliver tangible, measurable improvements in real-world rotary applications from turbine engines to industrial mixers.

Enabling High-Speed Operation

The primary killer of traditional seals at high speeds is heat buildup caused by friction. PTFE's low-friction nature mitigates this entirely.

This allows PTFE seals to maintain performance and integrity at surface speeds up to 35 m/s, a threshold far beyond the capability of most elastomeric seals.

Enhancing System Efficiency and Precision

By minimizing frictional drag, PTFE seals reduce the energy required to turn the shaft. This leads to lower power consumption and improved overall machine efficiency.

For precision equipment like robotics or CNC spindles, this reduction in drag also contributes to more responsive and accurate movement.

Extending Service Life and Reliability

PTFE compounds are highly resistant to wear and abrasion. When combined with their tolerance for heat and chemicals, the result is a significantly longer service life.

This translates directly to reduced maintenance, less downtime, and greater protection for critical components like bearings and shafts, enhancing the reliability of the entire system.

Surviving Imperfect Lubrication

While ideal lubrication is always preferred, PTFE seals can withstand periods of low lubrication and even short-term dry running. This provides a crucial safety margin that conventional seals lack, preventing catastrophic failure if lubrication is temporarily interrupted.

Understanding the Trade-offs and Considerations

While PTFE offers a revolutionary solution, it is not a universal replacement for all seal types. Being a trusted advisor means acknowledging its specific application profile and potential considerations.

Lack of Elastic "Memory"

Unlike rubber, PTFE is a plastic and has very little elasticity. It does not "spring back" into shape in the same way an elastomer does.

This means it is less forgiving of shaft imperfections, such as significant runout or scratches. Proper shaft surface finish is critical for optimal performance.

Installation Sensitivity

Because PTFE is a harder, less flexible material, the sealing lip can be damaged during installation if proper care is not taken. Specialized tools and procedures are often required to ensure the seal is not creased or nicked.

The Cost-to-Performance Ratio

PTFE seals typically have a higher upfront cost than standard nitrile or viton seals. The decision to use them is an engineering trade-off.

The higher initial investment is justified in applications where the cost of failure—in terms of downtime, equipment damage, or safety—far outweighs the cost of the seal itself.

Making the Right Choice for Your Application

Ultimately, the choice of sealing technology must be driven by the specific demands of your equipment and its operating environment.

- If your primary focus is high-speed rotation (e.g., turbines, high-RPM spindles): Choose PTFE for its low-friction properties that prevent the thermal breakdown common in other seals.

- If your primary focus is aggressive chemical environments (e.g., chemical pumps, processing equipment): Select PTFE for its chemical inertness, which ensures seal integrity where elastomers would quickly degrade.

- If your primary focus is extreme temperatures (e.g., aerospace, industrial ovens): Rely on PTFE for its vast operating temperature range, providing reliable sealing in conditions far too hot or cold for other materials.

- If your primary focus is a cost-sensitive, standard-duty application: A traditional elastomeric seal often remains the more practical and economical choice when extreme conditions are not a factor.

Choosing the right seal is not just about preventing leaks; it's about unlocking the full performance potential and reliability of your machinery.

Summary Table:

| Key Advantage | Performance Impact |

|---|---|

| Low Friction | Enables high-speed operation (up to 35 m/s), reduces energy consumption, and minimizes heat generation. |

| Thermal Stability | Operates reliably from -200°C to 260°C, preventing brittleness or degradation in extreme temperatures. |

| Chemical Inertness | Resists acids, bases, solvents, and aggressive oils, ideal for chemical, pharmaceutical, and food industries. |

| Long Service Life | Reduces maintenance, downtime, and protects critical components like bearings and shafts. |

Ready to enhance your rotary equipment's performance and reliability?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom lip seals, for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your machinery operates efficiently under extreme conditions, from high-speed rotations to aggressive chemical environments.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and durability.

Contact us today to discuss your specific requirements and let our solutions drive your success.

Get in touch with our experts now!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support