In short, extruded PTFE rods are used in food processing equipment because they are exceptionally non-stick, chemically inert, and can withstand a wide range of temperatures. This unique combination ensures that food remains pure and uncontaminated while preventing it from sticking to machinery, which improves both hygiene and operational efficiency.

The decision to use extruded Polytetrafluoroethylene (PTFE) is not based on a single benefit, but on its rare ability to simultaneously solve three critical challenges in food processing: ensuring absolute food safety, maximizing equipment uptime, and maintaining performance under extreme temperature fluctuations.

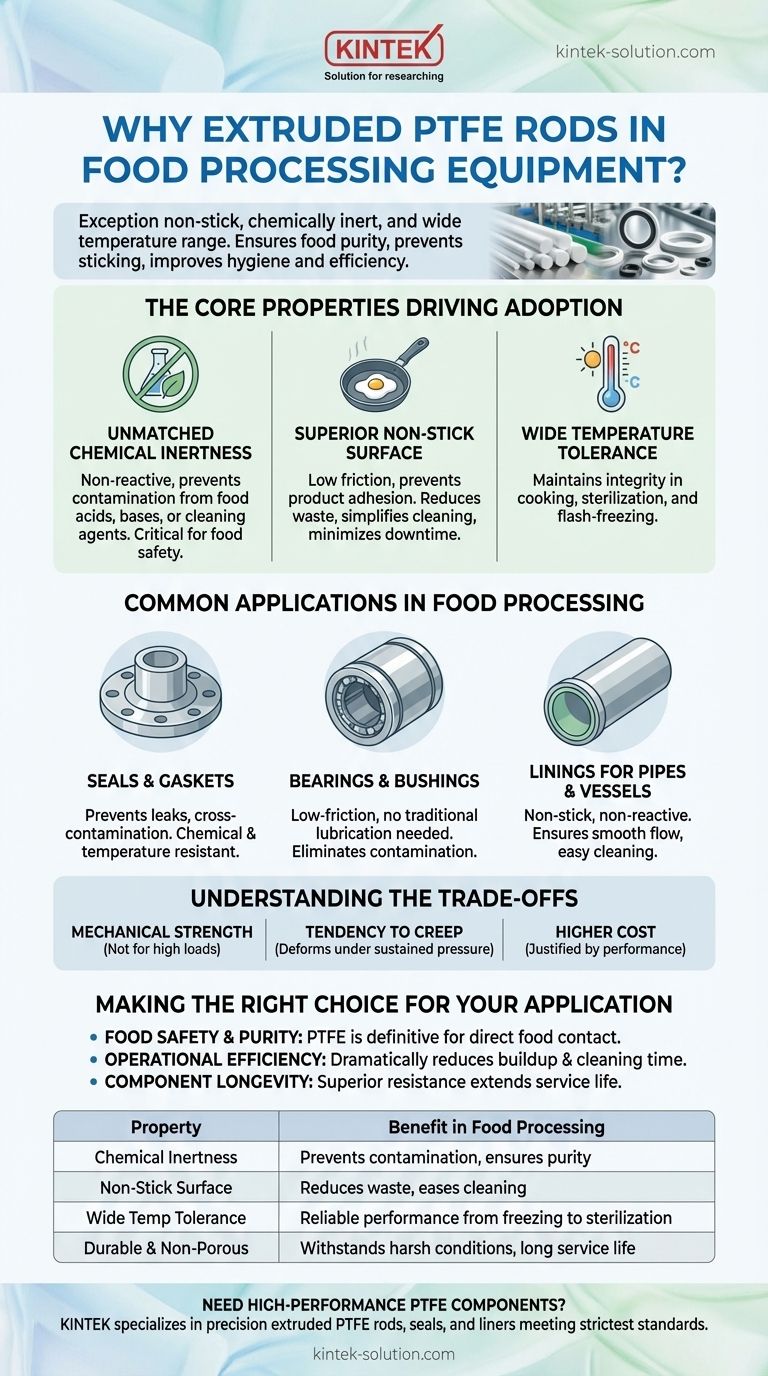

The Core Properties Driving Adoption

The suitability of extruded PTFE for food processing isn't an accident; it stems from a specific set of inherent material properties that are almost perfectly aligned with the industry's stringent requirements.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive materials known. It does not react with food acids, bases, or cleaning agents, ensuring that no harmful chemicals leach into the final product.

This inert and non-toxic nature is critical for meeting hygiene standards and regulatory requirements for materials that come into direct contact with food.

Superior Non-Stick Surface

PTFE has an extremely low coefficient of friction, giving it the famous "non-stick" quality. In food processing, this means products slide easily over surfaces without adhering.

This property is vital for reducing product waste and, just as importantly, simplifying the cleaning and sterilization processes, which minimizes equipment downtime.

Wide Temperature Tolerance

Food processing equipment often operates in extreme conditions, from high-temperature cooking and sterilization to flash-freezing.

PTFE maintains its integrity and performance across a vast temperature range, making it a reliable material for components used in nearly any stage of food production.

Enhanced Durability from Extrusion

The extrusion and sintering process used to create these rods results in a dense, strong, and non-porous material.

This structural integrity makes extruded PTFE highly durable and suitable for fabricating machine parts like bearings, seals, and gaskets that must withstand mechanical stress and harsh operating conditions.

Common Applications in Food Processing

The properties of extruded PTFE translate directly into its use for specific, critical components within food processing machinery.

Seals and Gaskets

PTFE's ability to create a tight seal, combined with its chemical and temperature resistance, makes it ideal for gaskets and O-rings.

These components are essential for preventing leaks and cross-contamination between different parts of a machine, a fundamental aspect of food safety.

Bearings and Bushings

The low-friction surface of PTFE allows it to be used for slide bearings, bushings, and other moving parts that operate without traditional lubrication.

This eliminates the risk of lubricant contamination, a major concern in food production environments.

Linings for Pipes and Vessels

Due to its non-stick and non-reactive properties, PTFE is often used to line pipes, chutes, and vessels that transport food ingredients.

This ensures a smooth, consistent flow of product and makes the equipment much easier to clean between batches.

Understanding the Trade-offs

While highly effective, extruded PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Mechanical Strength

PTFE is a relatively soft polymer. It is not suitable for high-load structural applications where the high tensile strength of metals is required.

Tendency to Creep

Under sustained pressure, especially at elevated temperatures, PTFE can be subject to "creep" or "cold flow," meaning it can slowly deform over time. This must be accounted for in the design of components like gaskets.

Higher Relative Cost

Specialized materials come at a cost. PTFE is typically more expensive than many commodity plastics, so its use is justified by specific performance needs related to safety, compliance, and durability.

Making the Right Choice for Your Application

Selecting the correct material is fundamental to designing and maintaining effective food processing systems.

- If your primary focus is food safety and purity: PTFE's chemical inertness and non-toxic, non-adsorbent properties make it the definitive choice for any part in direct contact with food.

- If your primary focus is operational efficiency: The material's non-stick surface dramatically reduces product buildup and simplifies cleaning, leading to less downtime and higher throughput.

- If your primary focus is component longevity in harsh environments: Extruded PTFE’s superior resistance to both chemicals and extreme temperatures ensures a longer, more reliable service life for critical machine parts.

Ultimately, specifying extruded PTFE is a strategic decision to prioritize safety, performance, and long-term reliability in demanding food-grade applications.

Summary Table:

| Property | Benefit in Food Processing |

|---|---|

| Chemical Inertness | Prevents contamination, ensures food purity |

| Non-Stick Surface | Reduces waste, eases cleaning |

| Wide Temperature Tolerance | Reliable performance from freezing to sterilization |

| Durable & Non-Porous | Withstands harsh conditions, long service life |

Need high-performance PTFE components for your food processing equipment? KINTEK specializes in manufacturing precision extruded PTFE rods, seals, liners, and custom parts that meet the strictest hygiene and durability standards. Our expertise ensures your equipment operates safely and efficiently, minimizing downtime and maximizing productivity. Contact us today to discuss your specific requirements and get a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability