In high-pressure, high-temperature applications, the best choice is rarely a standard, pure PTFE gasket. While pure PTFE has exceptional temperature resistance, its tendency to deform under pressure (a phenomenon known as creep) is its critical weakness. Therefore, modified or composite PTFE gaskets, such as filled or structured types, are almost always the superior and more reliable solution.

The core challenge with PTFE is not its temperature resistance, but its mechanical instability under load. The best gasket choice for demanding conditions is one that reinforces the PTFE to counteract its natural tendency to creep and cold flow, especially when heated.

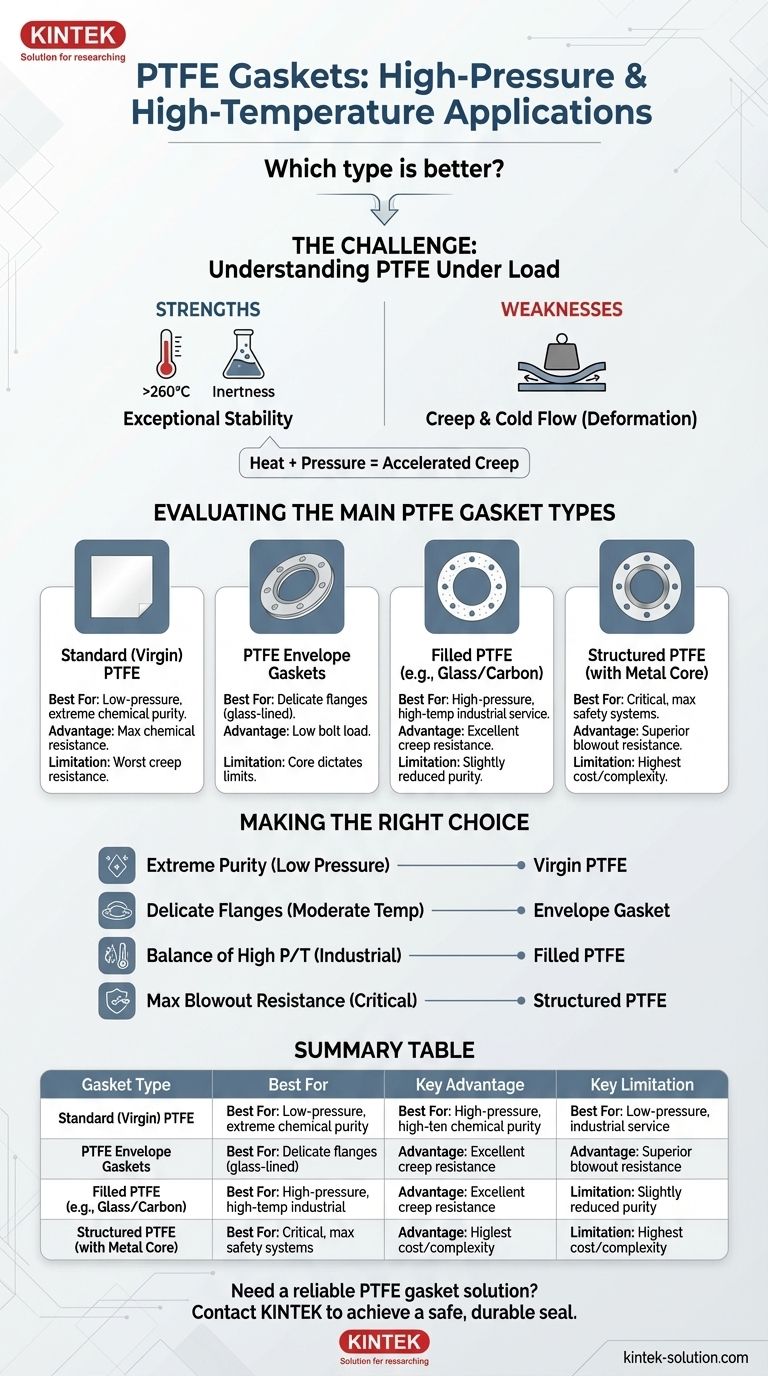

The Challenge: Understanding PTFE's Behavior Under Load

To select the right gasket, you must first understand the inherent properties of Polytetrafluoroethylene (PTFE) and how they interact under stress.

Exceptional Thermal and Chemical Stability

PTFE is renowned for its ability to withstand extreme temperatures, reliably performing in continuous service up to 260°C (500°F) with a melting point around 327°C (621°F).

Its near-universal chemical inertness also makes it a default choice for sealing aggressive media where other materials would quickly degrade.

The Critical Weakness: Creep and Cold Flow

The primary limitation of pure (virgin) PTFE is creep, also known as cold flow. When subjected to a constant compressive force, like the bolt load in a flange, the material slowly deforms and flows away from the point of pressure.

This deformation causes a loss of bolt torque and a reduction in sealing stress, which can ultimately lead to a leak.

The Combined Effect of Heat and Pressure

High temperature dramatically accelerates the rate of creep. A gasket that might hold a seal for months at room temperature could fail in hours or days when that same pressure is applied at an elevated temperature.

This combined effect is the central reason why pure PTFE is often unsuitable for critical high-temperature and high-pressure sealing applications.

Evaluating the Main PTFE Gasket Types

The industry has developed several types of PTFE gaskets, each designed to either leverage its strengths or mitigate its weaknesses.

Standard (Virgin) PTFE Gaskets

These are gaskets cut from a solid sheet of pure, unfilled PTFE.

Their main advantage is maximum chemical purity and resistance. However, they have the worst creep resistance of all types, making them best suited for low-pressure applications or where frequent re-torquing is possible.

PTFE Envelope Gaskets

These gaskets consist of a soft, compressible insert material (like rubber or a non-asbestos fiber) with a thin, protective "envelope" of PTFE on the outside.

They provide the chemical resistance of PTFE while requiring a lower bolt load to create a seal, which is ideal for delicate flanges (e.g., glass-lined steel). Their pressure and temperature limits are dictated by the core material, not just the PTFE.

Filled PTFE Gaskets

This is often the optimal solution for high-pressure and high-temperature service. In this design, inert filler materials like glass, carbon, or silica are blended with the PTFE resin before it's formed into a sheet.

These fillers act as a mechanical backbone within the material, drastically improving creep resistance and dimensional stability under load. They allow the gasket to maintain a seal under much higher pressures and temperatures than virgin PTFE.

Structured PTFE Gaskets

For the most extreme conditions, structured gaskets offer the highest level of security. These gaskets feature a PTFE sealing element mechanically bonded to or inserted within a rigid metallic core.

The metal core provides excellent rigidity and blowout resistance, while the PTFE provides the chemical resistance and sealing face. This design offers the best creep resistance and seal integrity for critical, high-pressure systems.

Understanding the Trade-offs

Choosing the right gasket involves balancing competing properties. There is no single "best" solution for every scenario.

Chemical Purity vs. Mechanical Strength

Virgin PTFE offers the highest purity, essential for food-grade or semiconductor applications. However, adding fillers to enhance mechanical strength slightly reduces the overall chemical resistance and introduces potential contaminants from the filler itself.

Sealability vs. Creep Resistance

PTFE envelope gaskets can seal with very low bolt stress, protecting fragile flanges. However, filled PTFE requires a higher bolt load to seat properly but will maintain that sealing stress far more effectively over time.

Cost vs. Performance

The cost and complexity increase with performance. Virgin PTFE is the least expensive, followed by envelope and filled gaskets. Structured PTFE gaskets are the most expensive but provide the highest margin of safety.

Making the Right Choice for Your Application

Your final decision must be based on the specific demands of your system—balancing pressure, temperature, chemical compatibility, and the nature of the flanges being sealed.

- If your primary focus is extreme chemical purity at lower pressures: Virgin PTFE is the correct choice.

- If your primary focus is sealing delicate flanges (like glass-lined steel) at moderate temperatures: A PTFE envelope gasket is often the ideal solution.

- If your primary focus is a balance of high pressure and high temperature in general industrial service: A filled PTFE gasket (e.g., glass or silica-filled) is the most reliable and common option.

- If your primary focus is maximum blowout resistance in critical, high-pressure service: A structured PTFE gasket with a metallic insert provides the highest level of safety and performance.

By understanding the fundamental trade-off between PTFE's chemical resistance and its mechanical weakness, you can confidently select the gasket that ensures a safe and durable seal for your specific application.

Summary Table:

| Gasket Type | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Standard (Virgin) PTFE | Extreme chemical purity, low-pressure applications | Maximum chemical resistance | Poor creep resistance, prone to cold flow |

| PTFE Envelope Gasket | Delicate flanges (e.g., glass-lined steel), moderate conditions | Low bolt load required, good for fragile flanges | Performance limited by core material |

| Filled PTFE (e.g., glass, carbon) | High-pressure, high-temperature industrial service | Excellent creep resistance, dimensional stability | Slightly reduced chemical purity |

| Structured PTFE (with metal core) | Critical, high-pressure systems requiring maximum safety | Superior blowout resistance, highest creep resistance | Highest cost and complexity |

Need a reliable PTFE gasket solution for your demanding application?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom gaskets—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication ensures you get a gasket that balances chemical resistance, temperature stability, and mechanical strength perfectly for your specific high-pressure, high-temperature needs.

Let us help you achieve a safe, durable seal. Contact our engineering team today to discuss your requirements, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications