In short, Teflon bushes are used in virtually any industry that requires high performance in demanding conditions. The most common adopters include the aerospace, automotive, chemical processing, food and pharmaceutical manufacturing, and high-tech electronics industries, where their unique properties solve critical engineering challenges.

The decision to use a Teflon bush is rarely about a single feature. It's about leveraging a unique combination of extreme chemical inertness, a wide operating temperature range, and an exceptionally low coefficient of friction to ensure reliability where conventional materials would fail.

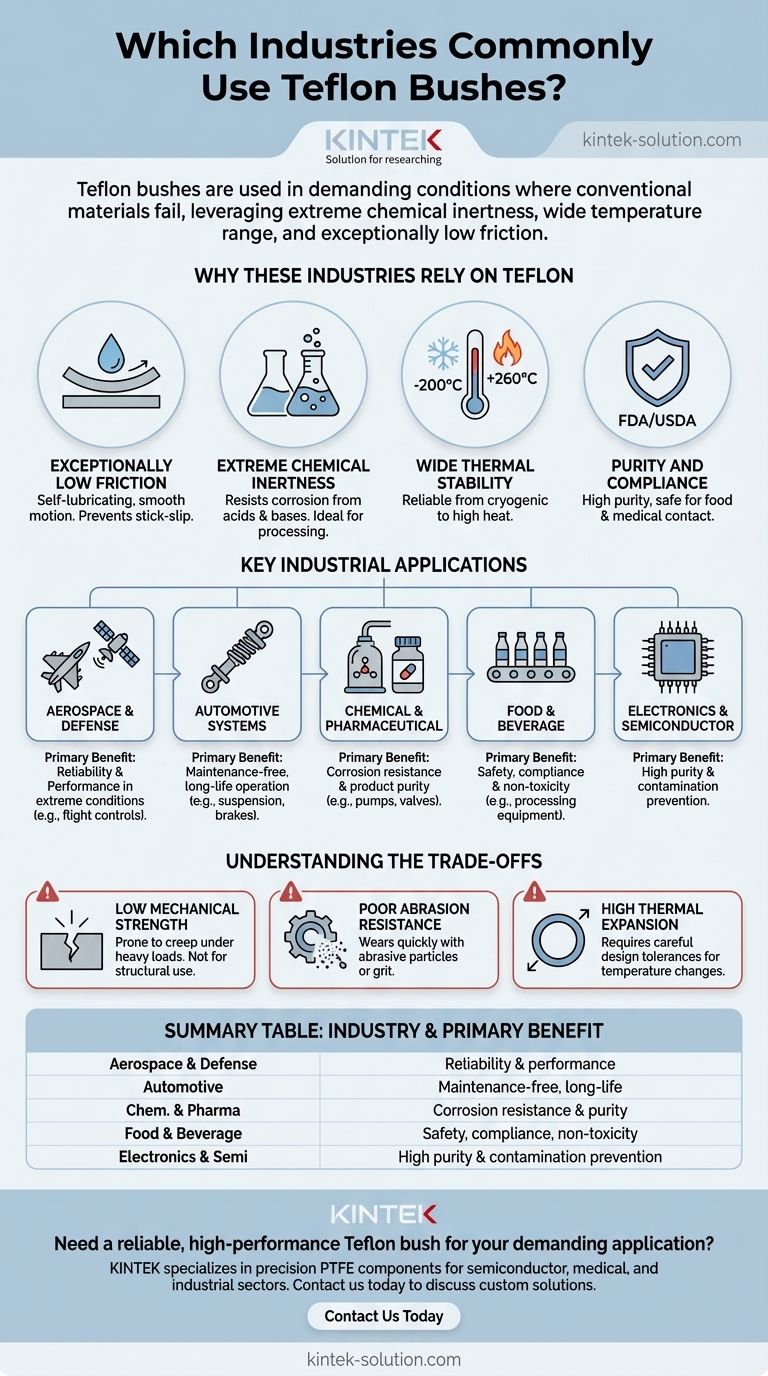

Why These Industries Rely on Teflon

The widespread use of Teflon (PTFE) bushes stems from a core set of material properties that make them ideal problem-solvers in harsh operational environments. Understanding these properties reveals why they are indispensable across so many sectors.

Exceptionally Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This allows for self-lubricating performance.

This is critical in machinery where external lubricants are impractical, undesirable, or could become a source of contamination. It ensures smooth, predictable motion and prevents the "stick-slip" phenomenon common in other materials.

Extreme Chemical Inertness

Teflon is famously non-reactive and resists corrosion from the vast majority of industrial chemicals, acids, and bases.

This makes it the default choice in chemical processing, pharmaceutical, and food manufacturing. The bush will not degrade or leach contaminants into the product, ensuring both process integrity and consumer safety.

Wide Thermal Stability

Teflon bushes perform reliably across a massive temperature range, from cryogenic lows (-200°C) to high-heat applications (up to 260°C or 500°F).

This stability is vital for aerospace and automotive applications, where components must function flawlessly in environments with extreme temperature fluctuations, from a cold start to peak operational heat.

Purity and Compliance

Due to its inert nature, Teflon can be manufactured to exceptionally high purity standards. Many grades are compliant with strict regulatory bodies.

This is non-negotiable for the medical, food, and semiconductor industries. FDA and USDA compliance ensures the material is safe for contact with consumables and does not introduce impurities into sensitive manufacturing processes.

A Closer Look at Key Industrial Applications

Different industries emphasize different benefits of Teflon, showcasing its versatility.

In Aerospace & Defense

Here, the primary drivers are reliability and performance under extreme conditions. Teflon bushes are used in flight control systems, landing gear, and other critical joints where failure is not an option and maintenance access is limited.

In Automotive Systems

The goal is maintenance-free, long-life operation. Teflon bushes are found in suspension systems, throttle shafts, and brake components, providing smooth movement without the need for grease in dirty, high-vibration environments.

In Chemical & Pharmaceutical Processing

The core need is corrosion resistance and purity. They are essential in pumps, valves, and mixers that handle aggressive chemicals, ensuring equipment longevity and preventing product contamination.

In Food & Beverage Manufacturing

Safety and compliance are paramount. Teflon bushes are used in conveyor systems and processing equipment where their non-stick, non-toxic, and moisture-resistant properties are invaluable.

Understanding the Trade-offs

While powerful, Teflon is not a universal solution. An objective assessment requires acknowledging its limitations.

Relatively Low Mechanical Strength

Teflon is a relatively soft material. It can be prone to "creep" or cold flow under sustained heavy loads, meaning it can deform over time. It is not suitable for high-load structural applications without reinforcement.

Poor Abrasion Resistance

While it has low friction, Teflon can wear quickly when subjected to hard, abrasive particles. In dusty or gritty environments, it may not last as long as hard metal or ceramic alternatives.

High Thermal Expansion

Teflon expands and contracts with temperature changes more than most metals. This must be carefully calculated into the design tolerances of an assembly to prevent binding or excessive looseness.

Making the Right Choice for Your Goal

Your application's primary goal should dictate your material choice.

- If your primary focus is reliability in extreme chemical or thermal environments: Teflon is almost certainly the correct choice due to its unmatched inertness and stability.

- If your primary focus is smooth, maintenance-free, self-lubricating motion: Teflon is a superior option, especially where external lubricants are undesirable.

- If your primary focus is purity and regulatory compliance: Virgin Teflon is the industry standard for food, medical, and semiconductor applications.

- If your primary focus is high-load mechanical strength with abrasive resistance: You should investigate reinforced PTFE composites or consider alternative materials like bronze or specialized polymers.

Ultimately, choosing a Teflon bush is a strategic engineering decision for environments where performance and reliability justify its specific advantages.

Summary Table:

| Industry | Primary Benefit of Teflon Bushes |

|---|---|

| Aerospace & Defense | Reliability & performance in extreme temperatures |

| Automotive | Maintenance-free, long-life operation |

| Chemical & Pharmaceutical | Corrosion resistance & product purity |

| Food & Beverage | Safety, compliance, & non-toxicity |

| Electronics & Semiconductor | High purity & contamination prevention |

Need a reliable, high-performance Teflon bush for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom bushes—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your components meet the strictest standards for chemical resistance, thermal stability, and purity.

Contact us today to discuss how our custom Teflon solutions can enhance your equipment's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance