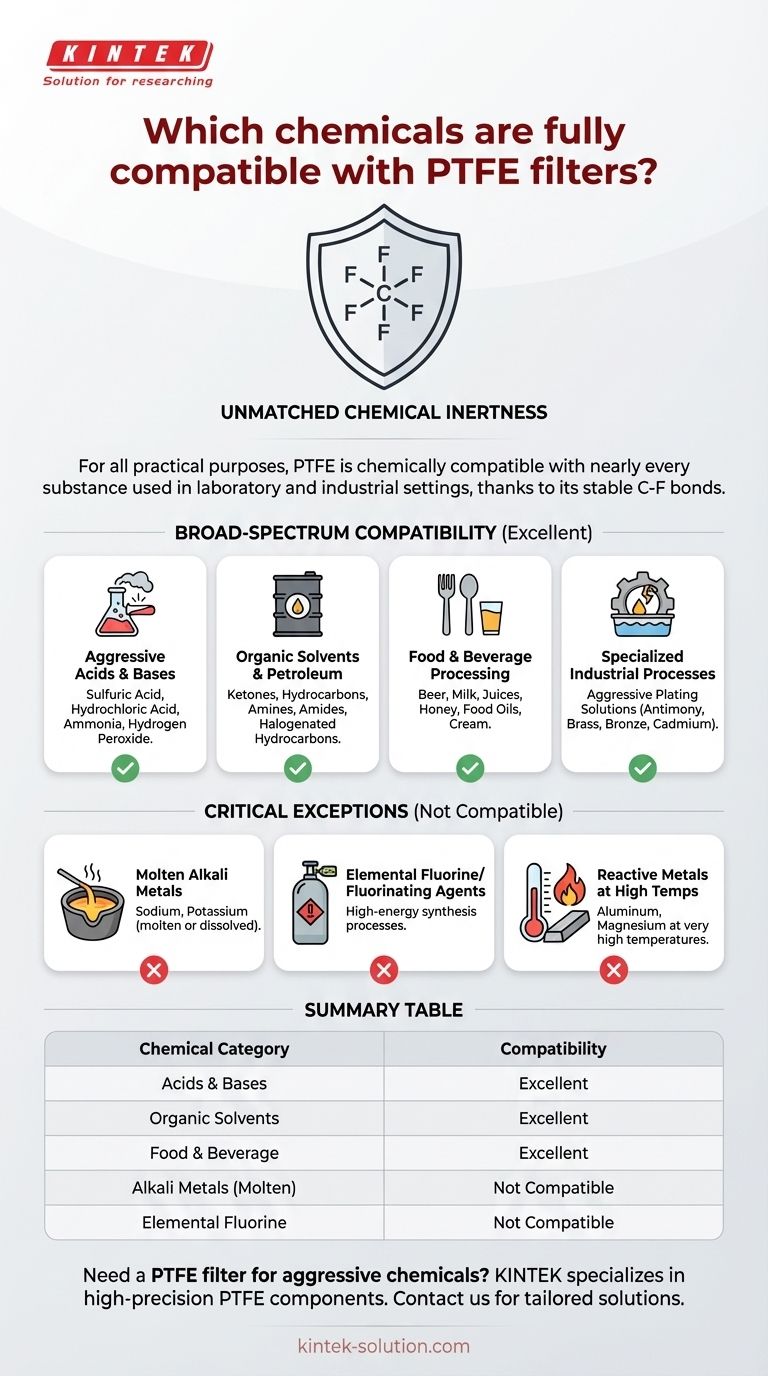

For all practical purposes, PTFE is chemically compatible with nearly every substance used in laboratory and industrial settings. Its extreme inertness makes it a default choice for filtering a vast range of chemicals, including aggressive acids, bases, alcohols, ketones, organic solvents, and petroleum products.

The exceptional chemical resistance of PTFE stems from its stable and strong carbon-fluorine bonds. While it is compatible with the vast majority of chemicals, its primary weakness is a vulnerability to highly reactive alkali metals, elemental fluorine, and certain potent fluorinating agents under specific conditions.

The Foundation of PTFE's Chemical Resistance

The Carbon-Fluorine Bond

The chemical structure of Polytetrafluoroethylene (PTFE) is the source of its remarkable performance. It consists of a long carbon chain completely shielded by a sheath of fluorine atoms.

These carbon-fluorine (C-F) bonds are exceptionally strong and stable, creating a non-reactive surface that effectively resists chemical attack.

Broad-Spectrum Compatibility

This molecular stability makes PTFE filters compatible with an extensive list of chemical families. This includes acids, bases, alcohols, ketones, aldehydes, esters, hydrocarbons, and organic oxides.

Verified Compatibility in Specific Applications

Aggressive Acids and Bases

PTFE filters are reliably used with strong acids like sulfuric acid and hydrochloric acid. They are also fully compatible with powerful bases and industrial chemicals like ammonia and hydrogen peroxide.

Organic Solvents and Petroleum Products

These filters show excellent compatibility with nearly all organic solvents. This list includes ketones, hydrocarbons, amines, amides, and halogenated hydrocarbons, making them ideal for complex organic synthesis and purification.

Food and Beverage Processing

PTFE is suitable for direct contact with a wide array of food products. Verified compatible substances include beer, milk, fruit juices, honey, various food oils (corn, olive, peanut), and cream.

Specialized Industrial Processes

The material's robustness extends to harsh industrial environments. For example, PTFE is compatible with numerous aggressive plating solutions used for antimony, brass, bronze, and cadmium plating.

Understanding the Critical Exceptions

Alkali Metals

The most significant incompatibility of PTFE is with alkali metals (like sodium or potassium) when they are in a molten state or dissolved in a solution. These highly reactive metals are powerful enough to disrupt PTFE's stable C-F bonds.

Elemental Fluorine and Strong Fluorinating Agents

While PTFE is a fluoropolymer, it can be attacked by elemental fluorine gas and other highly reactive fluorinating compounds. These conditions are typically encountered only in very specific, high-energy chemical synthesis processes.

Certain Metals at High Temperatures

At very high temperatures, reactive metals such as aluminum and magnesium can also degrade PTFE's structure. These conditions are rare and generally fall outside the scope of standard filtration tasks.

Making the Right Choice for Your Application

Your specific application will determine if PTFE is the correct choice.

- If your primary focus is general lab filtration: You can confidently use PTFE for virtually any common solvent, acid, or base without concern for degradation.

- If your primary focus is industrial or food-grade processing: PTFE is a safe and reliable choice, compatible with everything from harsh plating solutions to milk and oils.

- If your primary focus involves high-energy or elemental chemistry: You must verify that your process does not involve molten alkali metals, fluorine gas, or other potent fluorinating agents before selecting PTFE.

By understanding both its remarkable strengths and its well-defined limitations, you can leverage PTFE as one of the most dependable filtration materials available.

Summary Table:

| Chemical Category | Compatibility with PTFE Filters |

|---|---|

| Acids (e.g., Sulfuric, Hydrochloric) | Excellent |

| Bases (e.g., Ammonia) | Excellent |

| Organic Solvents (e.g., Ketones, Hydrocarbons) | Excellent |

| Food & Beverage (e.g., Milk, Oils, Juices) | Excellent |

| Alkali Metals (Molten) | Not Compatible |

| Elemental Fluorine / Fluorinating Agents | Not Compatible |

Need a PTFE filter that stands up to your most aggressive chemicals? KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, labware, and custom filters—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or high-volume production, we ensure chemical inertness, durability, and exacting standards. Contact us today to discuss your application and get a solution tailored to your needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications