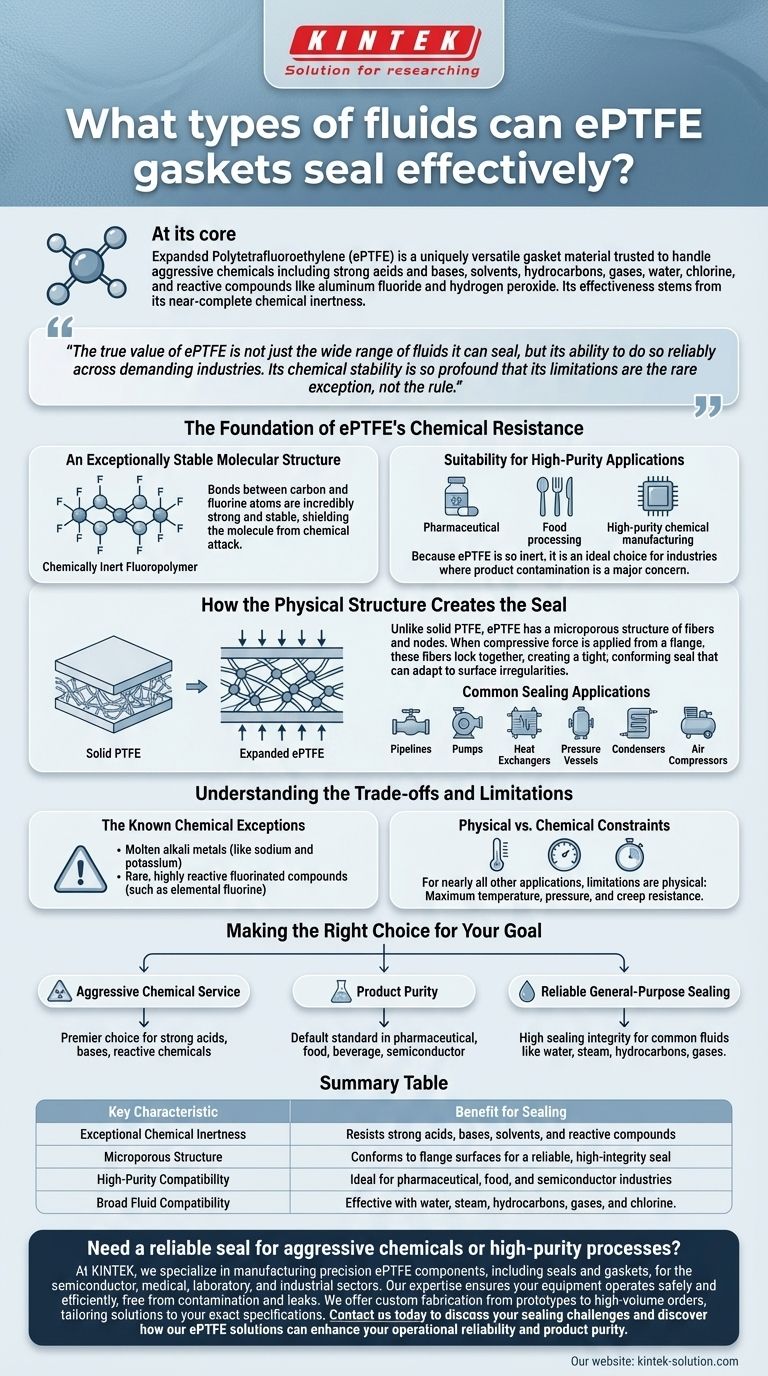

At its core, expanded Polytetrafluoroethylene (ePTFE) is a uniquely versatile gasket material capable of sealing an exceptionally broad range of fluids. It is trusted to handle aggressive chemicals including strong acids and bases, as well as solvents, hydrocarbons, gases, water, chlorine, and reactive compounds like aluminum fluoride and hydrogen peroxide. Its effectiveness stems from its near-complete chemical inertness.

The true value of ePTFE is not just the wide range of fluids it can seal, but its ability to do so reliably across demanding industries. Its chemical stability is so profound that its limitations are the rare exception, not the rule.

The Foundation of ePTFE's Chemical Resistance

The remarkable sealing capability of ePTFE is rooted in its fundamental molecular structure. This structure makes it one of the most chemically inert materials used in industrial sealing.

An Exceptionally Stable Molecular Structure

Polytetrafluoroethylene is a fluoropolymer. The bonds between its carbon and fluorine atoms are incredibly strong and stable, shielding the molecule from chemical attack.

This inherent stability means the material does not react with, degrade in, or leach into the vast majority of industrial fluids.

Suitability for High-Purity Applications

Because ePTFE is so inert, it is an ideal choice for industries where product contamination is a major concern.

This is why it is widely specified for applications in the pharmaceutical, food processing, and high-purity chemical manufacturing sectors.

How the Physical Structure Creates the Seal

Chemical resistance alone is not enough; a gasket must physically conform to the sealing surfaces to prevent leaks. The unique manufacturing process of ePTFE gives it a distinct advantage.

A Network of Intertwined Fibers

Unlike solid PTFE, ePTFE has a microporous structure of fibers and nodes. When compressive force is applied from a flange, these fibers lock together.

This creates a tight, conforming seal that can adapt to surface irregularities, ensuring high integrity even on worn or imperfect flanges.

Common Sealing Applications

This combination of chemical resistance and conformability makes ePTFE a go-to solution for sealing standard industrial equipment.

You will find it used in pipelines, pumps, heat exchangers, pressure vessels, condensers, and air compressors across the chemical, refining, and power generation industries.

Understanding the Trade-offs and Limitations

While ePTFE is exceptionally versatile, no material is universally perfect. Understanding its few chemical exceptions is critical for safe and effective application.

The Known Chemical Exceptions

The extreme stability of ePTFE means it is only vulnerable to a very small and specific class of chemicals.

Its primary chemical weaknesses are molten alkali metals (like sodium and potassium) and certain rare, highly reactive fluorinated compounds (such as elemental fluorine itself).

Physical vs. Chemical Constraints

For nearly all other applications, the limitations of ePTFE are physical, not chemical. Factors like maximum temperature, pressure, and creep resistance are the engineering constraints that must be considered during material selection, not the fluid being sealed.

Making the Right Choice for Your Goal

Selecting ePTFE is about matching its unique strengths to your specific operational demands.

- If your primary focus is aggressive chemical service: ePTFE is a premier choice for safely sealing strong acids, bases, and reactive chemicals where other materials would quickly fail.

- If your primary focus is product purity: Its inert, non-contaminating nature makes ePTFE the default standard in pharmaceutical, food and beverage, and semiconductor applications.

- If your primary focus is reliable general-purpose sealing: The material's ability to conform to imperfect surfaces provides a high degree of sealing integrity for common fluids like water, steam, hydrocarbons, and gases.

Ultimately, leveraging ePTFE gaskets provides a powerful combination of safety, reliability, and process purity for your most critical sealing challenges.

Summary Table:

| Key Characteristic | Benefit for Sealing |

|---|---|

| Exceptional Chemical Inertness | Resists strong acids, bases, solvents, and reactive compounds. |

| Microporous Structure | Conforms to flange surfaces for a reliable, high-integrity seal. |

| High-Purity Compatibility | Ideal for pharmaceutical, food, and semiconductor industries. |

| Broad Fluid Compatibility | Effective with water, steam, hydrocarbons, gases, and chlorine. |

Need a reliable seal for aggressive chemicals or high-purity processes?

At KINTEK, we specialize in manufacturing precision ePTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates safely and efficiently, free from contamination and leaks.

We offer custom fabrication from prototypes to high-volume orders, tailoring solutions to your exact specifications.

Contact us today to discuss your sealing challenges and discover how our ePTFE solutions can enhance your operational reliability and product purity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection