At its core, PTFE is the material of choice for sealing applications defined by extremes. Polytetrafluoroethylene (PTFE) gaskets are uniquely suited for environments involving aggressive chemicals, wide temperature ranges, and stringent purity requirements. They are the default solution in industries like chemical processing, pharmaceuticals, and food manufacturing where material inertness is paramount.

The suitability of a PTFE gasket is determined by its unparalleled chemical resistance and thermal stability. This makes it ideal for harsh services, but understanding its mechanical limitations—specifically its tendency to "creep" under load—is critical for correct application and long-term performance.

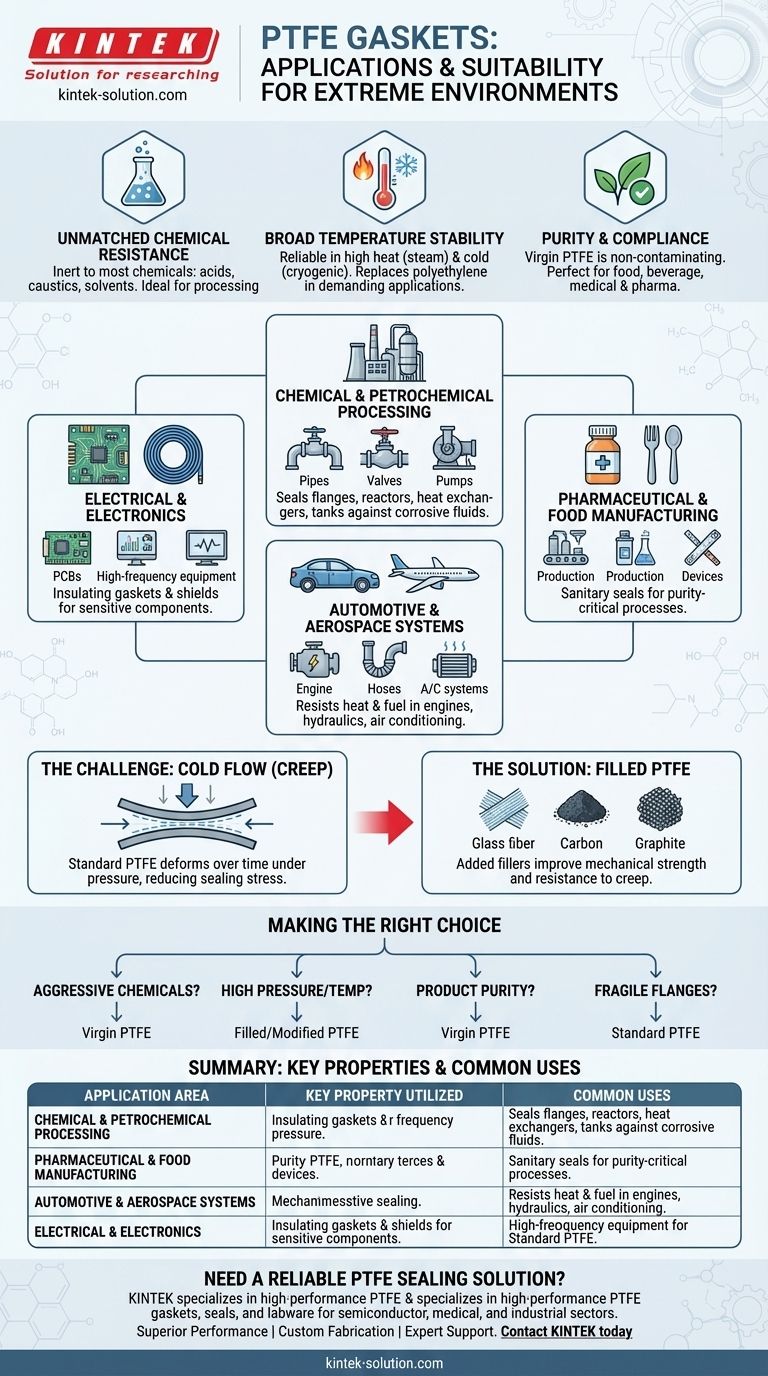

The Foundation: Why PTFE Excels in Demanding Environments

PTFE's effectiveness comes from a combination of three core properties. These characteristics make it a uniquely versatile sealing material for applications where others would quickly fail.

Unmatched Chemical Resistance

PTFE is virtually inert to most known chemicals. This makes it an essential material for sealing aggressive media, including strong acids, caustics, solvents, hydrocarbons, and refrigerants.

This property is why PTFE gaskets are ubiquitous in chemical processing plants, petrochemical facilities, and laboratories.

Broad Temperature Stability

PTFE gaskets perform reliably across an exceptionally wide temperature range. They maintain their integrity in high-heat systems like steam pipes and exhaust lines as well as in cold-pressing and cryogenic systems.

This thermal stability makes PTFE a suitable replacement for materials like polyethylene in demanding aerospace and computer applications.

Purity and Compliance

Virgin PTFE is inherently pure and non-contaminating, making it ideal for sanitary applications. Its non-reactive surface does not impart taste, color, or contaminants into the process media.

This is a critical requirement for food and beverage manufacturing, medical device components, and pharmaceutical production lines where product purity is non-negotiable.

Common Industrial and Mechanical Applications

Based on its core properties, PTFE is specified for a wide range of equipment and systems across multiple industries.

Chemical and Petrochemical Processing

This is the primary domain for PTFE gaskets. They are used to seal flanges on pipes, pumps, valves, and large-diameter vessels.

You will find them in heat exchangers, distillation towers, reactors, and tank linings where they prevent leaks of corrosive fluids and handle extreme process conditions.

Sealing Fragile Flanges

Standard PTFE is a relatively soft material. This allows it to conform easily to surface imperfections and create a tight seal with low bolt load.

This characteristic makes it perfect for sealing fragile flanges made from materials like Fibreglass Reinforced Plastic (FRP), PVC, or glass-lined steel, which could crack under the high compression required for harder gaskets.

Automotive and Aerospace Systems

PTFE's resistance to heat and corrosive fluids makes it valuable in high-performance vehicle applications.

It is used for engine oil seals, fuel hose linings, hydraulic seals, and components within air conditioning systems where reliability under pressure and temperature changes is critical.

Electrical and Electronics

PTFE is an excellent electrical insulator with a high dielectric strength. This property is leveraged to protect sensitive electronic components.

It is often used as an insulating gasket or seal for printed circuit boards and high-frequency communication equipment, shielding them from environmental factors and electrical interference.

Understanding the Trade-offs: The Challenge of "Cold Flow"

While PTFE has exceptional properties, it is not without limitations. Its primary mechanical weakness is a phenomenon known as creep, or "cold flow."

What is Cold Flow?

Cold flow is the tendency of a material to deform or "flow" away from a compressive load over time. Standard PTFE is soft and is particularly susceptible to this.

Under the pressure of a bolted flange, a standard PTFE gasket can slowly be squeezed out of place, reducing the sealing stress on the gasket.

The Impact on Sealing Performance

This loss of sealing stress can eventually lead to leaks. The issue is most prominent in applications with high pressure, significant temperature cycling, or frequent vibration.

Because of this, standard PTFE gaskets are often best suited for low-to-medium pressure applications and require careful installation procedures.

The Solution: Filled and Modified PTFE

To combat cold flow, PTFE is often blended with filler materials like glass fiber, carbon, or graphite. These filled PTFE gaskets retain the chemical resistance of PTFE while gaining significant mechanical strength.

These modified gaskets have vastly improved resistance to creep, making them suitable for high-pressure, high-temperature, and vacuum services where standard PTFE would fail.

Making the Right Choice for Your Application

Selecting the correct type of PTFE gasket requires matching the material's properties to the demands of your system.

- If your primary focus is aggressive chemical sealing: Standard, virgin PTFE is an excellent starting point due to its supreme chemical inertness.

- If your primary focus is high-pressure or high-temperature service: A filled or modified PTFE is necessary to resist cold flow and maintain a stable seal.

- If your primary focus is product purity (food, pharma): Virgin PTFE is almost always required to prevent any potential process contamination.

- If your primary focus is sealing fragile or uneven flanges: The softness and conformability of standard PTFE provide an effective seal without risking damage to the equipment.

By matching PTFE's unique profile to your specific operational demands, you ensure a reliable, long-lasting seal in even the most challenging environments.

Summary Table:

| Application Area | Key PTFE Property Utilized | Common Uses |

|---|---|---|

| Chemical & Petrochemical | Unmatched Chemical Resistance | Sealing flanges on pipes, pumps, valves, reactors, and heat exchangers handling corrosive fluids. |

| Pharmaceutical & Food | Purity and Compliance | Sanitary seals for production lines, medical devices, and food processing equipment. |

| Automotive & Aerospace | Broad Temperature Stability | Engine oil seals, fuel hose linings, hydraulic seals, and air conditioning components. |

| Electrical & Electronics | Excellent Electrical Insulation | Insulating gaskets for printed circuit boards and high-frequency communication equipment. |

| Fragile Flanges (FRP, Glass-lined) | Conformability & Low Bolt Load | Sealing flanges made from materials that could crack under high compression. |

Need a Reliable PTFE Sealing Solution?

KINTEK specializes in manufacturing high-performance PTFE components, including custom gaskets, seals, liners, and labware. Whether you operate in the semiconductor, medical, laboratory, or industrial sectors, we deliver precision-engineered solutions that meet your exact requirements.

- Superior Performance: Our PTFE components offer unmatched chemical resistance, thermal stability, and purity for your most demanding applications.

- Custom Fabrication: We provide tailored solutions from initial prototypes to high-volume production runs.

- Expert Support: Leverage our expertise to select the right PTFE grade—from virgin to filled compounds—to combat cold flow and ensure long-term reliability.

Let's engineer the perfect seal for your application. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers