In short, fluoropolymer-lined pipes (PTFE, FEP, PFA) are engineered for extreme industrial environments. They are primarily used in applications that involve transferring highly corrosive or high-purity fluids, often at elevated temperatures and low to moderate pressures. This makes them indispensable in industries like chemical processing, pharmaceuticals, and power generation.

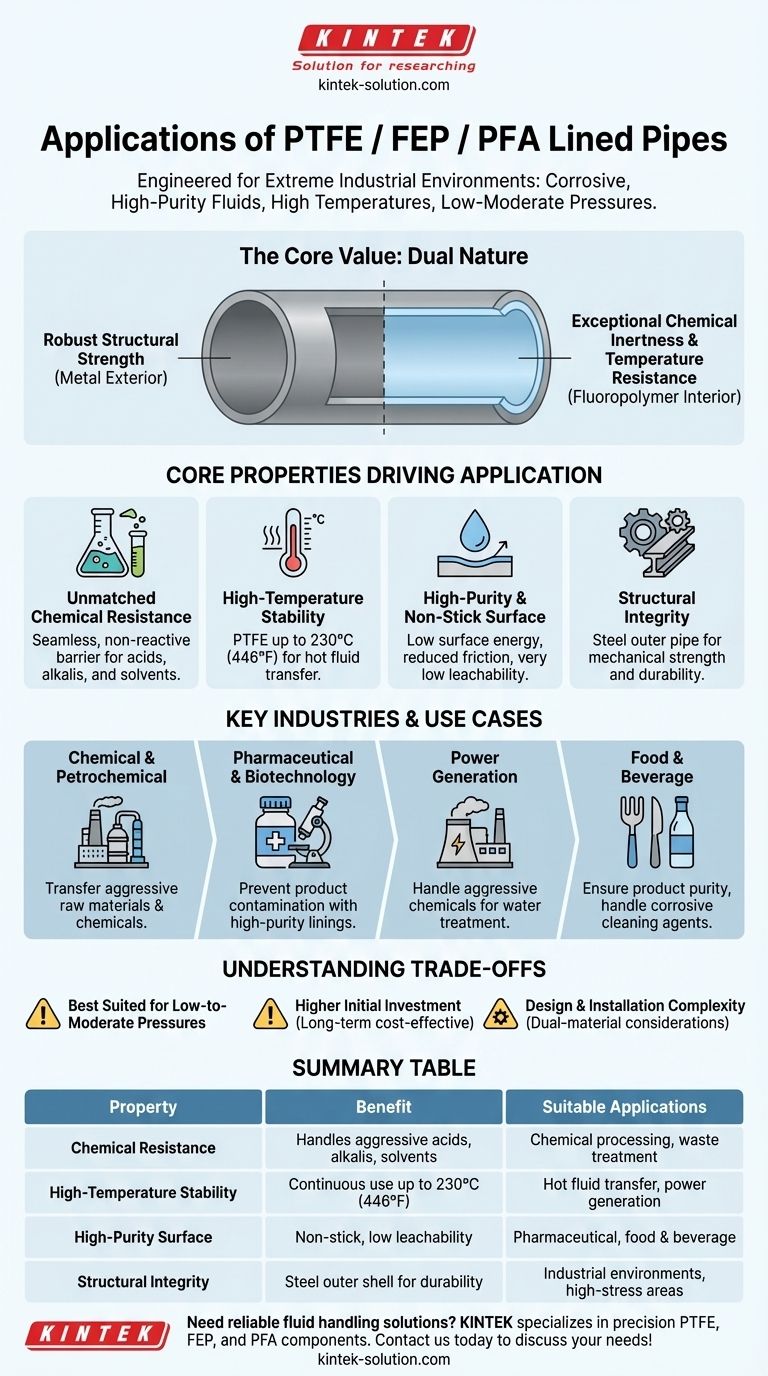

The core value of a lined pipe is its dual nature: it combines the robust structural strength of a metal exterior (typically steel) with the exceptional chemical inertness and temperature resistance of a fluoropolymer interior. This creates a system that can safely handle substances that would destroy most other materials.

The Core Properties Driving Application

The suitability of PTFE, FEP, and PFA lined pipes stems from a unique combination of material properties. Understanding these attributes clarifies exactly why they are chosen for the most demanding jobs.

Unmatched Chemical Resistance

The primary reason to specify a fluoropolymer-lined pipe is its near-universal chemical inertness. The lining acts as a seamless, non-reactive barrier.

This makes it the ideal solution for safely conveying strong, corrosive media such as acids, alkalis, and aggressive solvents that would quickly corrode even high-grade metal alloys.

High-Temperature Stability

These piping systems excel in processes that run hot. PTFE, in particular, can handle continuous service temperatures up to 230°C (446°F).

This allows for the transfer of hot, corrosive fluids without compromising the integrity of the piping system, a common failure point for many plastic or metal alternatives.

High-Purity and Non-Stick Surface

The surfaces of PTFE, FEP, and PFA are exceptionally smooth and non-stick. This property, known as low surface energy, provides two key benefits.

First, it reduces friction, ensuring smooth fluid flow and minimizing the energy required for pumping. Second, it prevents materials from sticking to the pipe wall and has very low leachability, which is critical for high-purity applications in the pharmaceutical and food industries.

Structural Integrity

While the fluoropolymer lining provides the chemical protection, the outer pipe—typically carbon or stainless steel—provides the mechanical strength.

This composite structure ensures the system can withstand the pressures and physical stresses of an industrial environment, offering durability and safety.

Key Industries and Use Cases

The properties of lined pipes make them essential components in several key industrial sectors where safety and reliability are paramount.

Chemical and Petrochemical Processing

This is the most common application. Lined pipes are used extensively to transfer raw materials, intermediate products, and finished chemicals that are too aggressive for standard piping.

Pharmaceutical and Biotechnology

In these industries, preventing product contamination is non-negotiable. The high purity and low leachability of PTFE and PFA linings ensure that the fluid being transferred remains uncontaminated.

Power Generation

Power plants often use aggressive chemicals for water treatment and other processes. Lined pipes and valves provide a long-lasting, low-maintenance solution for handling these substances.

Food and Beverage

Similar to pharmaceuticals, the food and beverage industry requires systems that do not contaminate the product. Lined pipes are used for handling corrosive cleaning agents and ensuring the purity of the final product.

Understanding the Trade-offs

While highly effective, lined pipe systems are not a universal solution. Acknowledging their operational boundaries is key to successful implementation.

Best Suited for Low-to-Moderate Pressures

The references highlight their use in low-pressure process applications. While the steel housing provides significant strength, the lining itself can be a limiting factor under very high pressure or full vacuum conditions, especially when combined with high temperatures.

Higher Initial Investment

Fluoropolymer-lined pipe systems typically have a higher upfront cost compared to standard steel or some alloy pipes.

However, this initial expense is often justified as a cost-effective long-term solution due to dramatically increased service life, reduced downtime, and lower maintenance requirements in corrosive environments.

Design and Installation Complexity

The dual-material nature requires careful consideration during design and installation. Factors like the different thermal expansion rates of the steel and the polymer liner must be accounted for to prevent stress and failure during temperature cycling.

Making the Right Choice for Your Goal

Selecting the correct piping material is a critical decision based on the specific demands of your process.

- If your primary focus is maximum corrosion resistance: Lined pipe is one of the most reliable solutions for handling aggressive acids, bases, and solvents that would destroy other materials.

- If your primary focus is high-purity processing: The inert, non-leaching nature of PTFE and PFA linings makes them an ideal choice for preventing contamination in pharmaceutical or food-grade applications.

- If your primary focus is longevity in a harsh environment: The combination of a protective liner and a strong outer shell provides a durable, low-maintenance system that extends the life of your entire process line.

Ultimately, choosing a fluoropolymer-lined pipe is a strategic decision to ensure safety, reliability, and long-term value in your most demanding fluid-handling applications.

Summary Table:

| Property | Benefit | Suitable Applications |

|---|---|---|

| Chemical Resistance | Handles aggressive acids, alkalis, solvents | Chemical processing, waste treatment |

| High-Temperature Stability | Continuous use up to 230°C (446°F) | Hot fluid transfer, power generation |

| High-Purity Surface | Non-stick, low leachability | Pharmaceutical, food & beverage |

| Structural Integrity | Steel outer shell for durability | Industrial environments, high-stress areas |

Need reliable fluid handling solutions for corrosive or high-purity applications? KINTEK specializes in manufacturing precision PTFE, FEP, and PFA components—including custom-lined pipes, seals, liners, and labware—for semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures durability, contamination-free performance, and long-term cost savings. Contact us today to discuss your specific needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability