In short, these bearings excel in high-load, low-speed applications where external lubrication is difficult, undesirable, or impossible. They are specifically designed for both dry-running and intermittently lubricated systems that demand low friction, self-lubrication, and good corrosion resistance.

The core value of a Metal-Polymer Bronze Backed PTFE bearing lies in its composite structure. It intelligently combines the high mechanical strength of a bronze backing with the exceptionally low friction and self-lubricating properties of a PTFE liner, creating a solution for problems that a single material cannot solve.

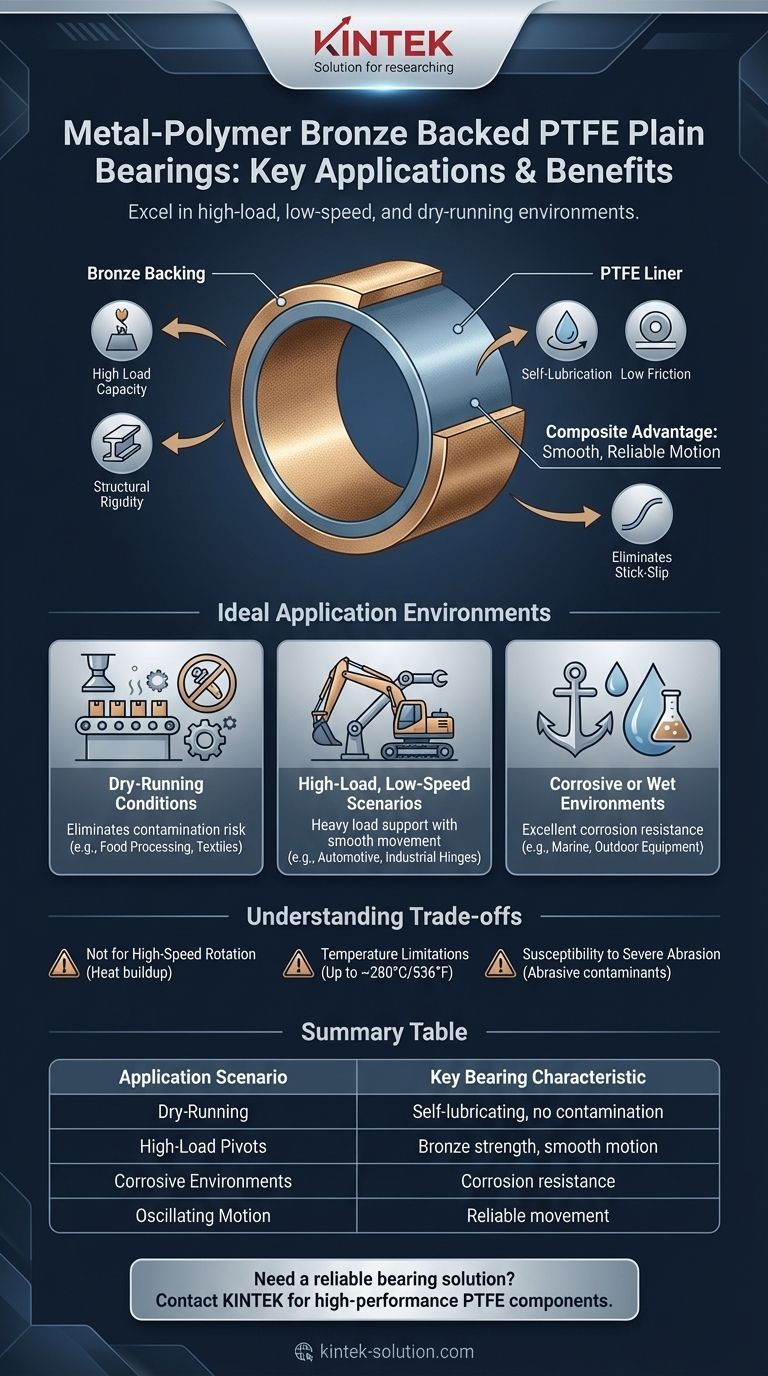

Deconstructing the Bearing: Why It Works

To understand where these bearings fit, you must first understand how their construction directly translates to performance benefits. They are not a single material, but a layered system where each component serves a distinct purpose.

The Bronze Backing: Strength and Stability

The foundation of the bearing is a solid bronze backing. This metal shell provides the high load-carrying capacity and structural rigidity needed to operate under significant pressure without deforming.

Bronze also offers superior corrosion resistance compared to a standard steel backing, making it a better choice for damp or mildly chemical environments.

The PTFE Liner: Self-Lubrication and Low Friction

Bonded to the backing is a composite liner whose primary component is Polytetrafluoroethylene (PTFE). This layer is the source of the bearing's self-lubricating and low-friction characteristics.

This allows for smooth operation without the need for grease or oil, a critical feature for applications where contamination is a concern or maintenance access is limited.

The Composite Advantage: Smooth, Reliable Motion

This combination of a hard, strong backing with a low-friction sliding surface is ideal for eliminating "stick-slip"—the jerky motion common in lubricated bearings during start-up. This ensures smooth, predictable movement, especially in applications with frequent stops, starts, or oscillating motions.

Ideal Application Environments

Based on their unique construction, these bearings are the optimal choice in several key scenarios.

Dry-Running Conditions

These bearings are a premier solution for applications where external lubricants cannot be used. This includes machinery for food processing, textiles, or any environment where grease or oil could contaminate the product or attract abrasive dust.

High-Load, Low-Speed Scenarios

Think of pivot points on construction equipment, linkage joints in automotive systems, or hinges on heavy industrial doors. In these cases, the bearing must support a heavy load but moves at a relatively low speed or only oscillates. The high strength of the bronze and the low friction of the PTFE are perfectly matched for this.

Corrosive or Wet Environments

The inherent corrosion resistance of both the bronze backing and the chemically inert PTFE liner makes these bearings highly suitable for marine applications, outdoor equipment, and systems exposed to washing or chemicals.

Understanding the Trade-offs

No engineering solution is universal. Being objective means recognizing limitations.

Not for High-Speed Rotation

These are plain bearings designed for sliding contact. They are not suited for continuous, high-speed rotational applications where heat buildup would quickly degrade the PTFE liner. For high RPMs, rolling-element bearings (like ball bearings) are the appropriate choice.

Temperature Limitations

While robust, the PTFE polymer layer has an upper service temperature limit (typically around 280°C / 536°F). In extremely high-temperature environments, you would need to consider specialized all-metal or ceramic bearings.

Susceptibility to Severe Abrasion

The self-lubricating liner is softer than a metal bearing surface. If an application involves extremely abrasive contaminants (like sand or grinding dust) without proper sealing, these particles can embed in the liner and accelerate wear on the shaft.

Making the Right Choice for Your Application

Use these guidelines to determine if this bearing type is the correct solution for your project.

- If your primary focus is maintenance-free operation: These bearings are ideal for sealed-for-life joints or locations where regular greasing is impractical.

- If your primary focus is smooth motion under heavy load: Use them for pivots, linkages, and hinges where stick-slip performance is critical.

- If your primary focus is corrosion or chemical resistance: The bronze and PTFE combination offers a reliable solution for machinery operating in damp or mildly corrosive environments.

- If your primary focus is high-speed rotation: You should evaluate rolling-element bearings (e.g., ball or roller bearings) as a more suitable alternative.

By understanding their composite nature, you can confidently specify these versatile bearings for the demanding applications they were designed to solve.

Summary Table:

| Application Scenario | Key Bearing Characteristic |

|---|---|

| Dry-Running Conditions (e.g., Food Processing) | Self-lubricating PTFE liner eliminates contamination risk |

| High-Load, Low-Speed Pivots (e.g., Construction Equipment) | Bronze backing provides high strength; PTFE ensures smooth motion |

| Corrosive/Wet Environments (e.g., Marine Applications) | Bronze and PTFE offer excellent corrosion resistance |

| Oscillating or Intermittent Motion | Eliminates stick-slip for reliable, predictable movement |

Need a reliable bearing solution for a demanding application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom Bronze Backed PTFE plain bearings. Our precision production and custom fabrication capabilities—from prototypes to high-volume orders—ensure you get a bearing perfectly suited for your specific needs in the semiconductor, medical, laboratory, or industrial sectors.

Contact our experts today to discuss how we can enhance your equipment's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability