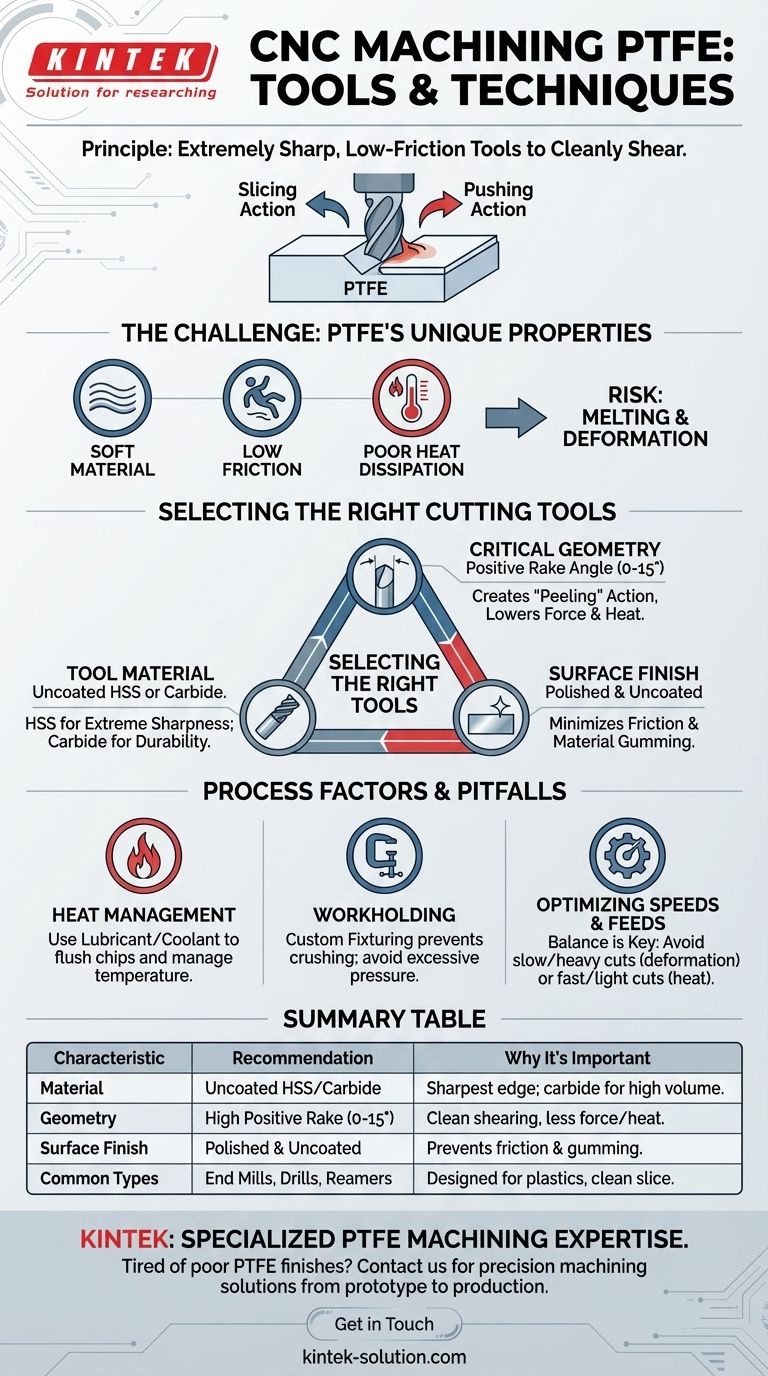

To successfully machine PTFE, you need cutting tools with extremely sharp edges, a specific geometry, and low-friction surfaces. The most common and effective tools are uncoated high-speed steel (HSS) or carbide end mills, drills, and reamers that feature a high positive rake angle to cleanly shear the soft material rather than pushing it.

The core principle for machining PTFE is not about using the hardest tool, but the sharpest and slickest. Success depends on using tools designed to slice the material with minimal friction and heat generation, preventing the melting and deformation that plague common machining attempts.

The Challenge: Understanding PTFE's Unique Properties

Polytetrafluoroethylene (PTFE) is unlike metals or even most other plastics. Its unique characteristics are precisely what make specialized tooling a necessity.

Why PTFE Behaves Differently

PTFE is exceptionally soft and has a very low coefficient of friction. It also has poor thermal conductivity, meaning it doesn't dissipate heat well.

This combination means that friction from a cutting tool quickly builds up heat in a localized area, which can cause the material to melt, gum up the tool, and result in a poor surface finish.

The Risk of Pushing vs. Cutting

Due to its softness, using a tool that isn't perfectly sharp or has the wrong geometry will cause the material to deform and push away from the cutting edge instead of shearing cleanly.

This leads to dimensional inaccuracy, burrs, and a warped final part. The goal is always a clean, slicing action.

Selecting the Right Cutting Tools

The right tool selection revolves around three factors: the tool's material, its geometry, and its surface finish.

Tool Material: HSS or Carbide

Both high-speed steel (HSS) and carbide tools are effective for PTFE. HSS can often be ground to a finer, sharper edge, which is a significant advantage.

Carbide or Stellite-tipped tools offer superior wear resistance and will maintain their sharpness for longer production runs, but the initial sharpness is paramount.

Critical Geometry: The Positive Rake Angle

The most important geometric feature is a positive top rake angle, typically between 0 and 15 degrees.

A positive rake creates a sharper "peeling" action that lifts the chip away from the workpiece. This significantly reduces cutting forces, minimizes heat buildup, and ensures a cleaner cut.

Surface Finish: Polished and Uncoated

The tool's cutting edges should be highly polished. This reduces friction against the soft PTFE, further preventing heat generation and material buildup on the tool.

Crucially, uncoated tools are preferred. Coatings like Titanium Nitride (TiN), while excellent for metals, can increase friction when cutting soft polymers like PTFE. An uncoated, polished surface is slicker and generates less heat.

Understanding the Trade-offs and Pitfalls

The cutting tool is only one part of the equation. Failure to control the surrounding process can undermine even the best tool selection.

Heat Management is Non-Negotiable

Even with the right tool, high speeds and feed rates can generate destructive heat. Using a lubricant or coolant is often necessary to manage temperature and help flush away chips.

Workholding Can Damage the Part

PTFE's softness makes it highly susceptible to being crushed or deformed by standard machine vises or clamps. Custom fixturing that supports the workpiece broadly without applying excessive pressure is often required to maintain dimensional stability.

Optimizing Speeds and Feeds

You must optimize your spindle speed, feed rate, and depth of cut. A slow, heavy cut can cause deformation, while a fast, light cut can generate excessive heat. Finding the right balance through testing is critical for achieving a quality finish and accurate dimensions.

Making the Right Choice for Your Goal

Select your tooling and approach based on the specific outcome you need to achieve.

- If your primary focus is high precision and a fine surface finish: Prioritize extremely sharp, polished HSS or carbide tools with a high positive rake angle and use coolant.

- If your primary focus is general shaping or roughing: Standard sharp carbide tools will work, but monitor for any signs of heat buildup or material gumming.

- If your primary focus is creating threads or holes: Use drills and taps specifically designed for plastics, which feature wider flutes and sharp cutting lips to prevent tearing.

By choosing tools that slice cleanly and minimize friction, you can turn a challenging material like PTFE into a predictable and reliable component.

Summary Table:

| Tool Characteristic | Recommendation for PTFE | Why It's Important |

|---|---|---|

| Material | Uncoated High-Speed Steel (HSS) or Carbide | Provides the sharpest edge; carbide offers longer life for high-volume runs. |

| Geometry | High Positive Rake Angle (0-15°) | Ensures a clean shearing action, reducing cutting force and heat. |

| Surface Finish | Polished and Uncoated | Minimizes friction to prevent heat buildup and material gumming. |

| Common Tool Types | End Mills, Drills, Reamers | Designed for plastics with sharp edges to slice cleanly. |

Tired of PTFE parts that melt, warp, or have poor finishes?

Machining PTFE requires specialized knowledge and tooling to overcome its unique challenges. At KINTEK, we specialize in the precision machining of high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors.

We understand that success depends on using the sharpest tools, optimal geometries, and precise process controls to prevent heat buildup and ensure dimensional accuracy. Let our expertise guide your project from prototype to high-volume production.

Contact KINTEB today to discuss your PTFE machining needs and get a quote for clean, precise, and reliable components.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs