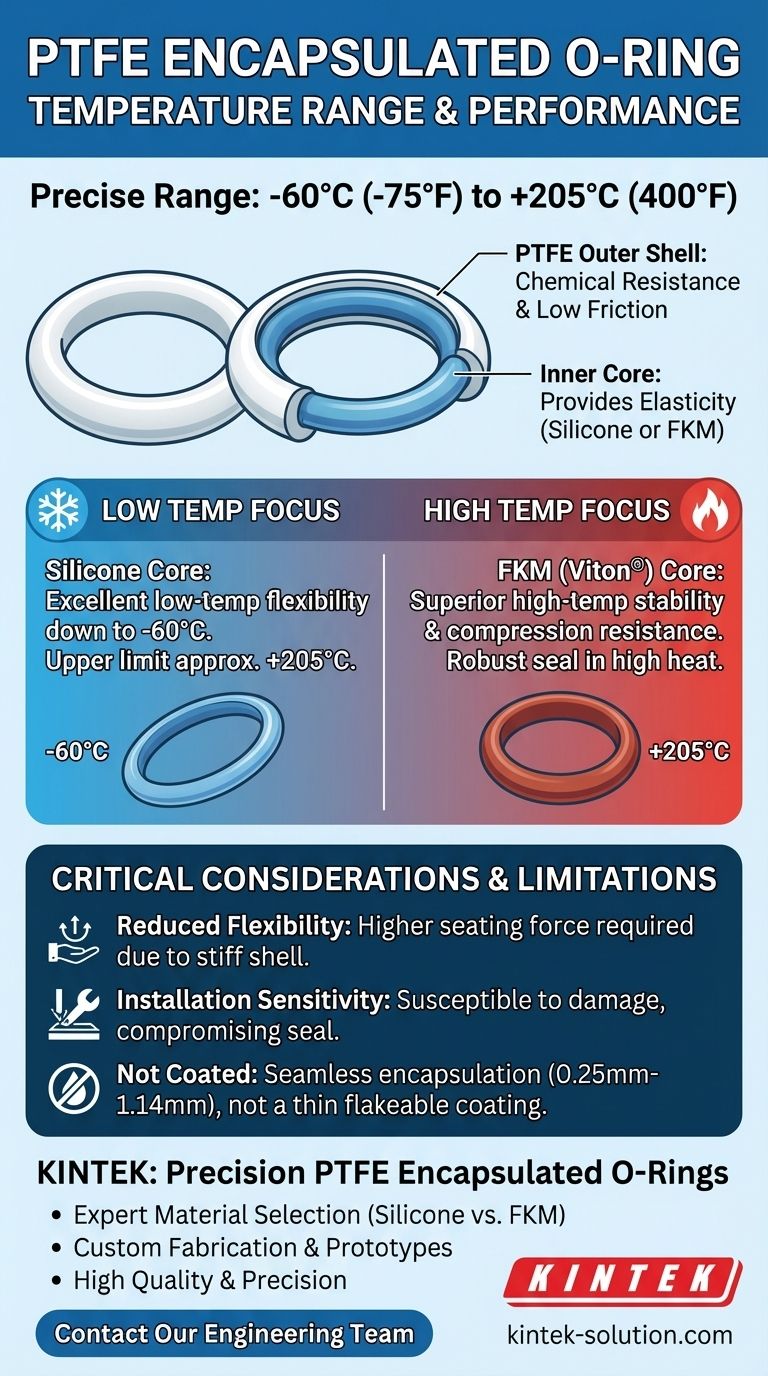

To be precise, a PTFE encapsulated O-ring can typically withstand a temperature range from -60°C (-75°F) to +205°C (400°F). However, this range is not absolute; it is critically dependent on the material used for the O-ring's internal core, which provides its elasticity.

The true operational temperature range of an encapsulated O-ring is a system property, defined by the limits of both its outer PTFE shell and its inner elastomeric core. To ensure reliable sealing, you must select a combination where both components are suited for your application's full temperature spectrum.

Deconstructing the Encapsulated O-Ring

To understand the temperature rating, you first need to understand the O-ring's construction. It consists of two distinct components that work together.

The Outer Shell: Chemical Resistance and Low Friction

The external shell is a seamless encapsulation of a fluoropolymer, most commonly PTFE (Polytetrafluoroethylene), but also FEP or PFA.

This shell provides the primary benefits: exceptional chemical inertness and a very low coefficient of friction. Pure PTFE can handle a much wider temperature range, sometimes cited from -200°C to 260°C.

The Inner Core: The Source of Elasticity

The rigid PTFE shell has poor memory and elasticity. The O-ring gets its "springiness" and sealing force from a solid elastomeric core inside the shell.

The choice of this core material is the single most important factor determining the seal's performance at temperature extremes.

How the Core Material Dictates the Temperature Range

The two most common core materials are Silicone and FKM (Viton®), each offering a different set of compromises between high and low-temperature capabilities.

Silicone Core O-Rings

A silicone core is the standard choice for applications requiring excellent low-temperature flexibility.

This core is what allows the assembled O-ring to function effectively down to -60°C. However, its upper temperature limit is generally around +205°C (400°F).

FKM (Viton®) Core O-Rings

An FKM core provides superior high-temperature stability and better resistance to compression set (permanent deformation) than silicone.

While FKM doesn't perform as well as silicone at extreme low temperatures, it provides a more robust seal in high-heat environments and when exposed to aggressive chemicals. Its overall range makes it a versatile, heavy-duty option.

Understanding the Trade-offs and Limitations

While offering a unique combination of chemical and temperature resistance, encapsulated O-rings are not a universal solution. You must be aware of their specific limitations.

Encapsulated vs. Coated O-Rings

It is critical to distinguish between an encapsulated O-ring and a coated one. An encapsulated O-ring has a substantial, seamless shell (0.25mm to 1.14mm thick).

A coated O-ring has only a very thin layer of PTFE applied to the surface. This coating can easily flake or rub off, especially in dynamic applications, and offers no additional chemical resistance.

Reduced Flexibility

The stiff PTFE shell makes the entire O-ring much more rigid than a standard elastomer O-ring. This means it requires a higher seating force to create an effective seal.

Installation Sensitivity

Due to their rigidity, encapsulated O-rings can be challenging to install, especially in smaller sizes. They are more susceptible to being scratched or damaged during installation, which can compromise the integrity of the PTFE shell and lead to seal failure.

Making the Right Choice for Your Application

Selecting the correct encapsulated O-ring requires matching the core material to your specific operational demands.

- If your primary focus is extreme low-temperature performance (down to -60°C): Choose a PTFE encapsulated O-ring with a silicone core.

- If your primary focus is high-temperature stability and superior compression resistance: An FKM (Viton®) core is the more robust choice for demanding conditions.

- If your application involves dynamic motion or requires high elasticity: Re-evaluate if an encapsulated O-ring is the best fit, as its rigidity can be a significant drawback.

Understanding the interplay between the core and the shell is the key to leveraging the unique benefits of encapsulated O-rings without being caught by their limitations.

Summary Table:

| Component | Material | Key Temperature Characteristic |

|---|---|---|

| Outer Shell | PTFE | Excellent chemical resistance; can handle -200°C to +260°C alone |

| Inner Core | Silicone | Best for low temps: Effective down to -60°C |

| Inner Core | FKM (Viton®) | Best for high temps: Superior stability up to +205°C |

Need a High-Performance PTFE Encapsulated O-Ring?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom encapsulated O-rings for the semiconductor, medical, laboratory, and industrial sectors. We understand that the right core material is critical for your application's temperature and chemical requirements.

We provide:

- Expert Material Selection: Guidance on choosing between silicone and FKM cores for optimal performance in your specific temperature range.

- Custom Fabrication: From prototype development to high-volume production, ensuring a perfect fit and seal for your equipment.

- Quality and Precision: Every component is manufactured to the highest standards for reliable, long-lasting performance.

Let us help you solve your toughest sealing challenges. Contact our engineering team today for a consultation on your custom O-ring needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How is PTFE used in industrial processes? Maximize Safety and Efficiency