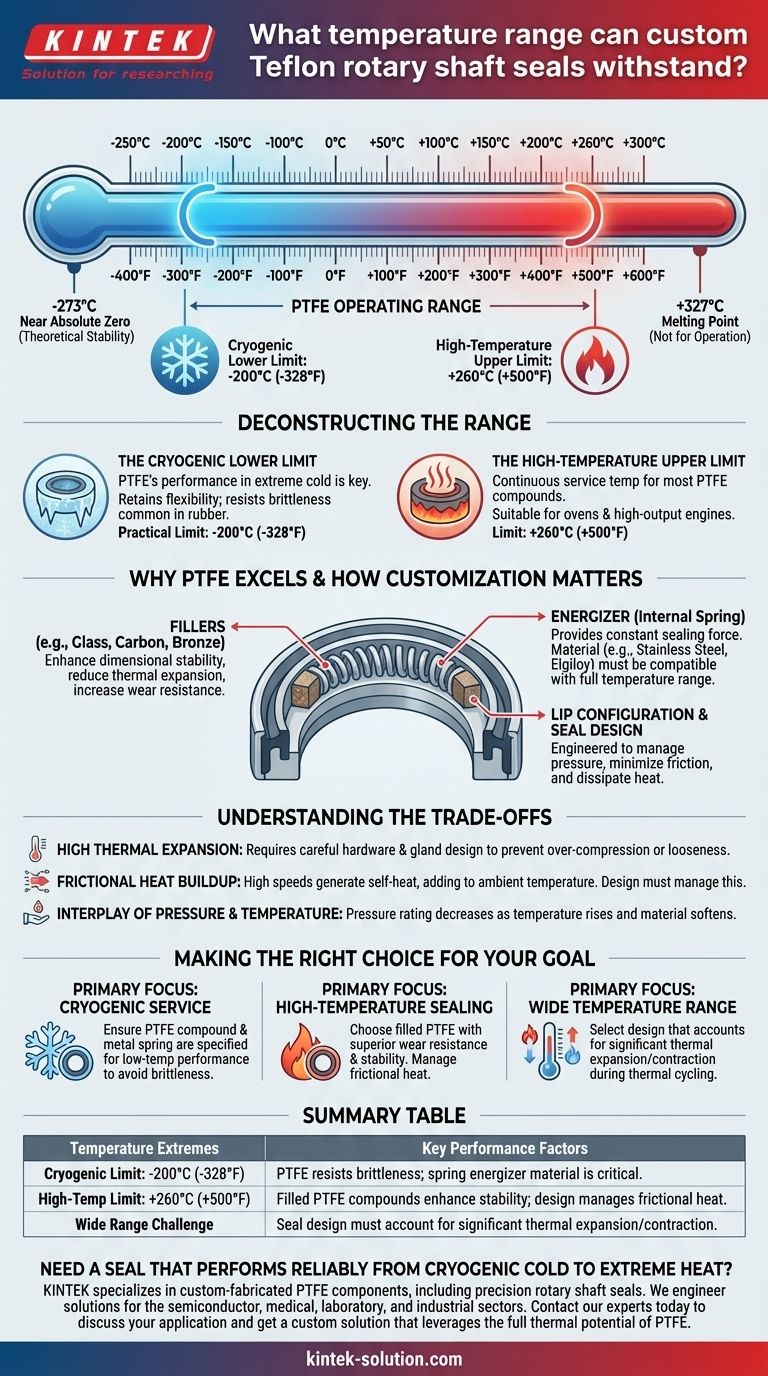

In short, custom Teflon (PTFE) rotary shaft seals have an exceptionally wide operating temperature range, typically from -200°C to +260°C (-328°F to +500°F). This remarkable thermal stability makes PTFE a premier choice for applications involving both cryogenic cold and extreme heat, far surpassing the capabilities of traditional elastomeric seals.

The key takeaway is that while the base PTFE material defines the potential temperature range, the seal's actual performance at those extremes depends entirely on its specific design—including the filler materials, spring energizer, and lip configuration.

Deconstructing the Temperature Range

To properly specify a seal, it's crucial to understand what these temperature limits mean in practice. The numbers represent the material's inherent capabilities, which are then refined through engineering.

The Cryogenic Lower Limit

PTFE's performance in extreme cold is one of its defining features. Unlike many rubber compounds that become brittle and fail at low temperatures, PTFE retains a degree of flexibility.

The practical service limit is often cited as -200°C (-328°F). In a theoretical sense, the material itself is stable down to nearly absolute zero at -273°C (-459°F).

The High-Temperature Upper Limit

The commonly accepted continuous service temperature for most PTFE compounds is +260°C (+500°F). This makes it suitable for demanding environments like industrial ovens or high-output engines.

The absolute melting point of PTFE is around 327°C (620°F). Operating near this temperature is not recommended as the material will begin to lose its structural integrity and critical sealing properties.

Why PTFE Excels at Temperature Extremes

This thermal stability is a result of PTFE's molecular structure. The powerful chemical bonds between carbon and fluorine atoms are exceptionally stable and require a tremendous amount of thermal energy to break.

Beyond the Base Material: How Customization Affects Performance

A rotary shaft seal is more than just a piece of PTFE. It is an engineered system where customization is critical to surviving extreme temperatures.

The Impact of Fillers

Virgin PTFE is rarely used alone in dynamic seals. Fillers are blended in to enhance specific properties.

These fillers—such as glass, carbon, or bronze—can improve dimensional stability, reduce thermal expansion, and increase wear resistance, all of which are vital for maintaining a consistent seal across a wide temperature spectrum.

The Importance of the Energizer

Many Teflon seals are "energized" by an internal spring that provides the constant force needed to seal effectively.

The material of this spring (e.g., stainless steel or a specialty alloy like Elgiloy) has its own temperature limits that must be compatible with the application's full range.

Lip Configuration and Seal Design

The physical shape of the seal lip is engineered to manage pressure and minimize friction. In high-speed, high-temperature applications, a design that dissipates heat effectively is essential to prevent the seal interface from exceeding its temperature limits.

Understanding the Trade-offs

While PTFE offers an incredible temperature range, its properties present unique design challenges that must be addressed.

High Thermal Expansion

PTFE expands and contracts with temperature changes more than most metals. The hardware and gland design must account for this to ensure the seal isn't over-compressed when hot or too loose when cold.

Frictional Heat Buildup

In high-speed rotary applications, the friction at the seal lip generates significant heat. This self-generated heat adds to the ambient temperature and can potentially push the material past its safe operating limit if not managed.

Interplay of Pressure and Temperature

A seal's ability to handle pressure is often inversely related to its operating temperature. As temperatures rise, the material softens slightly, which can reduce its maximum pressure rating. This must be considered in any high-pressure, high-temperature system.

Making the Right Choice for Your Goal

Selecting the correct seal requires matching the full design to the specific environmental challenges.

- If your primary focus is cryogenic service: Ensure both the PTFE compound and the metal spring energizer are specified for low-temperature performance to avoid brittleness.

- If your primary focus is high-temperature sealing: Choose a filled PTFE compound that offers superior wear resistance and thermal stability, and ensure the design manages frictional heat.

- If your primary focus is a wide temperature range: Work with a manufacturer to select a design that accounts for significant thermal expansion and contraction to maintain seal integrity during thermal cycling.

Ultimately, leveraging the full potential of Teflon seals comes from a clear understanding of how a complete, customized design operates within your specific thermal environment.

Summary Table:

| Temperature Extremes | Key Performance Factors |

|---|---|

| Cryogenic Limit: -200°C (-328°F) | PTFE resists brittleness; spring energizer material is critical. |

| High-Temp Limit: +260°C (+500°F) | Filled PTFE compounds enhance stability; design manages frictional heat. |

| Wide Range Challenge | Seal design must account for significant thermal expansion/contraction. |

Need a seal that performs reliably from cryogenic cold to extreme heat?

KINTEK specializes in custom-fabricated PTFE components, including precision rotary shaft seals. We engineer solutions for the semiconductor, medical, laboratory, and industrial sectors, ensuring your seals are optimized for your specific temperature, pressure, and speed requirements—from prototypes to high-volume production.

Contact our experts today to discuss your application and get a custom solution that leverages the full thermal potential of PTFE.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments