Technological advancements in PTFE lined check valves are primarily focused on enhancing material durability, optimizing operational efficiency, and creating more compact, lightweight designs. These improvements move beyond basic corrosion resistance to deliver higher performance and reliability in demanding industrial applications.

The core evolution in PTFE lined check valves is a shift from a simple protective barrier to a highly engineered component. Modern advancements are less about a single breakthrough and more about integrated improvements in materials, fluid dynamics, and mechanical design that collectively lower energy consumption and improve system uptime.

The Evolution Beyond Basic Corrosion Resistance

Historically, the primary value of a PTFE liner was its chemical inertness. Today, advancements address the entire performance profile of the valve, from the energy it consumes to the space it occupies.

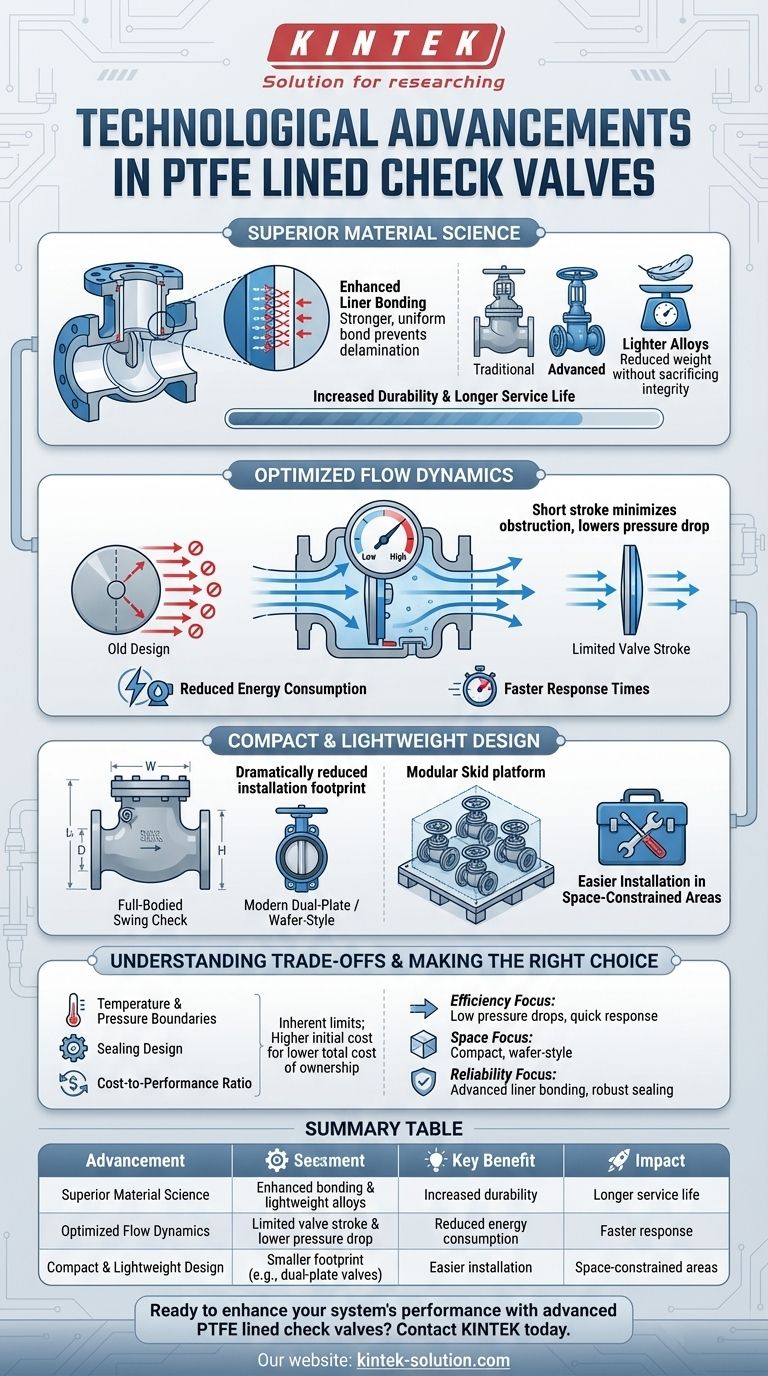

Advancement 1: Superior Material Science

The term "state-of-the-art materials" refers to improvements in both the PTFE liner and the structural body of the valve.

Modern liners feature enhanced application processes that ensure a stronger, more uniform bond to the valve body, reducing the risk of delamination or liner collapse under vacuum or high-temperature conditions. This leads to greater durability and a longer service life.

Simultaneously, the valve bodies themselves are being constructed from stronger yet lighter alloys, contributing to the overall reduction in weight without sacrificing structural integrity.

Advancement 2: Optimized Flow Dynamics

A key area of innovation is in minimizing the valve's interference with the fluid passing through it.

Modern designs feature a limited valve stroke, meaning the internal components (like the disc or plate) only need to move a short distance to open fully. This minimizes obstruction, resulting in a lower pressure drop across the valve.

A lower pressure drop directly translates to reduced energy consumption for pumps, as they work less to move fluid through the system. This also contributes to faster response times, allowing the valve to open and close more quickly.

Advancement 3: Compact and Lightweight Design

Space is a premium in modern industrial plants and modular skids. Manufacturers have responded by engineering valves that are significantly smaller and lighter.

This is particularly evident in designs like the dual-plate check valve. Their compact, wafer-style construction allows them to be installed easily between two flanges, dramatically reducing the installation footprint compared to older, full-bodied swing check valves.

Understanding the Trade-offs

While modern PTFE lined valves offer significant advantages, it's crucial to understand their operational context and limitations.

Limitation: Temperature and Pressure Boundaries

PTFE is a polymer and has inherent temperature and pressure limitations that all-metal valves do not. While advancements have pushed these boundaries, they remain a critical consideration. Exceeding these specifications can lead to liner failure.

Consideration: The Importance of Sealing Design

While PTFE provides excellent chemical resistance, the overall sealing capability of the valve depends on its mechanical design. For instance, some designs provide a superior, tighter seal against backflow than traditional swing check valves, which is critical in applications like chemical dosing.

The Cost-to-Performance Ratio

Advanced designs and materials often carry a higher initial purchase price. The trade-off is a lower total cost of ownership, achieved through reduced maintenance needs (due to non-stick properties), lower energy costs, and increased system reliability.

Making the Right Choice for Your Goal

Selecting the appropriate valve requires aligning its specific advancements with your primary operational objective.

- If your primary focus is maximizing system efficiency: Prioritize valves with documented low pressure drops and quick-response internal mechanisms.

- If your primary focus is fitting into a constrained space: Look for modern, compact designs like dual-plate or wafer-style valves.

- If your primary focus is ensuring maximum reliability in highly corrosive service: Investigate valves with advanced liner bonding technologies and robust, non-stick sealing surfaces.

By understanding these specific advancements, you can select a valve that functions not just as a necessary safeguard, but as a component that actively enhances your system's performance.

Summary Table:

| Advancement | Key Benefit | Impact |

|---|---|---|

| Superior Material Science | Enhanced liner bonding & lightweight alloys | Increased durability & longer service life |

| Optimized Flow Dynamics | Limited valve stroke & lower pressure drop | Reduced energy consumption & faster response |

| Compact & Lightweight Design | Smaller footprint (e.g., dual-plate valves) | Easier installation in space-constrained areas |

Ready to enhance your system's performance with advanced PTFE lined check valves?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom check valves, for the semiconductor, medical, laboratory, and industrial sectors. Our valves are engineered with the latest advancements to deliver superior corrosion resistance, lower your total cost of ownership, and improve operational efficiency.

Whether you need a prototype or a high-volume order, we provide custom fabrication to meet your exact specifications.

Contact us today to discuss how our PTFE solutions can solve your most demanding fluid handling challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems