The three primary spring options available for PTFE seals are Cantilever (often called a V-spring), Canted Coil, and Helical Ribbon springs. Each is designed with a distinct geometry to provide a specific type of mechanical force to the PTFE seal jacket. This energizing force is critical for ensuring the seal maintains contact and performs reliably, especially when system pressure is low or variable.

The type of spring energizer within a PTFE seal is not an interchangeable detail; it is a critical design choice. The spring's geometry—be it Cantilever, Canted Coil, or Helical—directly dictates the seal's performance characteristics and suitability for specific applications, such as rotary, reciprocating, or static service.

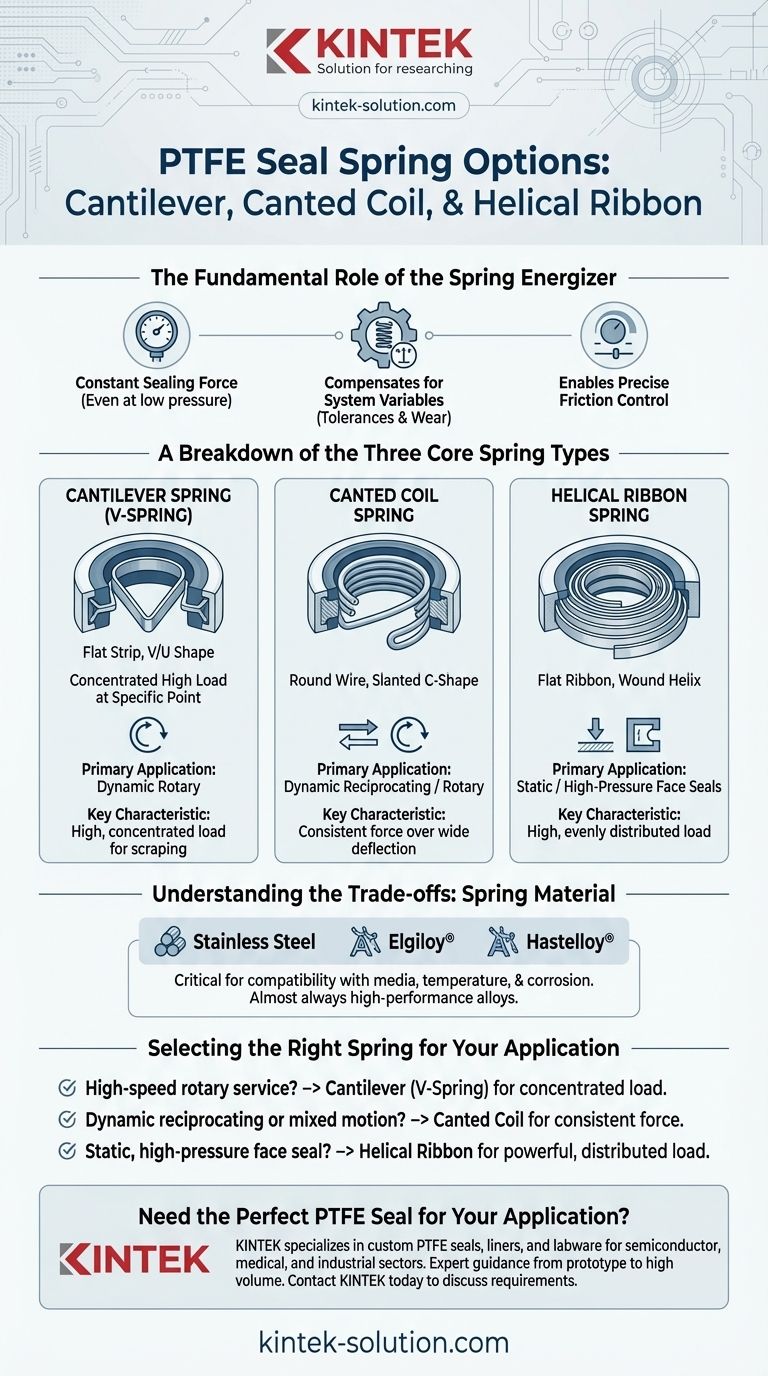

The Fundamental Role of the Spring Energizer

Before comparing spring types, it's essential to understand why the spring exists. A spring-energized seal combines a low-friction PTFE jacket with a metal spring to create a highly effective sealing system.

Providing a Constant Sealing Force

The spring provides a continuous radial force, pushing the PTFE seal lips against the mating surface. This ensures a tight seal even at zero or very low system pressures, where a standard seal might otherwise fail to actuate.

Compensating for System Variables

An energizer spring automatically compensates for minor imperfections. It adjusts for variations in gland tolerances and accounts for normal seal wear over the component's lifespan, ensuring consistent performance.

Enabling Precise Friction Control

Unlike a solid elastomer like an O-ring, the spring's force can be engineered with high precision. This allows for more accurate control over friction, a critical factor in dynamic applications.

A Breakdown of the Three Core Spring Types

The choice of spring is determined entirely by the demands of the application. Each type offers a different load profile.

The Cantilever Spring (V-Spring)

This energizer is formed from a flat metal strip bent into a characteristic 'V' or 'U' shape. It functions like a beam, concentrating a high load onto a specific point on the seal lip.

This high load concentration makes it an excellent choice for dynamic rotary applications, where it can effectively scrape away media and maintain a strong sealing line.

The Canted Coil Spring

A canted coil spring is made from round wire that is coiled and slanted into a 'C' shape. Its unique geometry provides a relatively constant force across a wide range of deflections.

This consistent loading makes it extremely versatile. It is the preferred choice for both rotary and dynamic reciprocating applications, where motion can cause pressure fluctuations.

The Helical Ribbon Spring

This spring is fabricated from a flat ribbon of metal wound into a helix, similar to a traditional coil spring. This design provides a very high, evenly distributed load.

Its high load characteristic is ideal for static or very slow dynamic applications, particularly in face seals where a powerful and consistent force is needed across a broad surface.

Understanding the Trade-offs: Spring Material

The spring's performance is not just a function of its geometry; the material it's made from is equally critical for system longevity and reliability.

The Importance of Material Selection

The spring material must be compatible with the system's media, temperature, and potential for corrosion. An incorrect material choice can lead to spring failure and, consequently, seal failure.

Common Corrosion-Resistant Alloys

To ensure durability, energizer springs are almost always made from high-performance alloys. Common choices include:

- Stainless Steel: A baseline for good corrosion resistance in many industrial applications.

- Elgiloy®: A cobalt-chromium-nickel alloy known for its exceptional strength, corrosion resistance, and performance at extreme temperatures.

- Hastelloy®: A nickel-molybdenum alloy offering outstanding resistance to highly corrosive chemical agents.

Selecting the Right Spring for Your Application

Your final choice should be guided by the specific motion and environmental conditions of your system.

- If your primary focus is high-speed rotary service: The Cantilever (V-spring) provides the high, concentrated load needed for effective sealing and media scraping.

- If your primary focus is dynamic reciprocating or mixed motion: The Canted Coil spring offers a consistent force over a wide deflection range, making it the most versatile and reliable option.

- If your primary focus is a static, high-pressure face seal: The Helical Ribbon spring delivers the powerful, evenly distributed load required for stationary applications.

Matching the spring's design to the application's demands is the key to unlocking the full performance potential of a PTFE seal.

Summary Table:

| Spring Type | Primary Application | Key Characteristic |

|---|---|---|

| Cantilever (V-Spring) | Dynamic Rotary | High, concentrated load for scraping |

| Canted Coil | Dynamic Reciprocating/Rotary | Consistent force over wide deflection |

| Helical Ribbon | Static / High-Pressure Face Seals | High, evenly distributed load |

Need the Perfect PTFE Seal for Your Application?

Choosing the right spring energizer is critical for seal performance, longevity, and reliability. KINTEK specializes in the precision manufacturing of custom PTFE seals—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We provide expert guidance on spring selection and deliver custom fabrication from prototypes to high-volume orders, ensuring your seals meet exact specifications for motion, pressure, and media compatibility.

Contact KINTEK today to discuss your PTFE seal requirements and get a solution engineered for your success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech