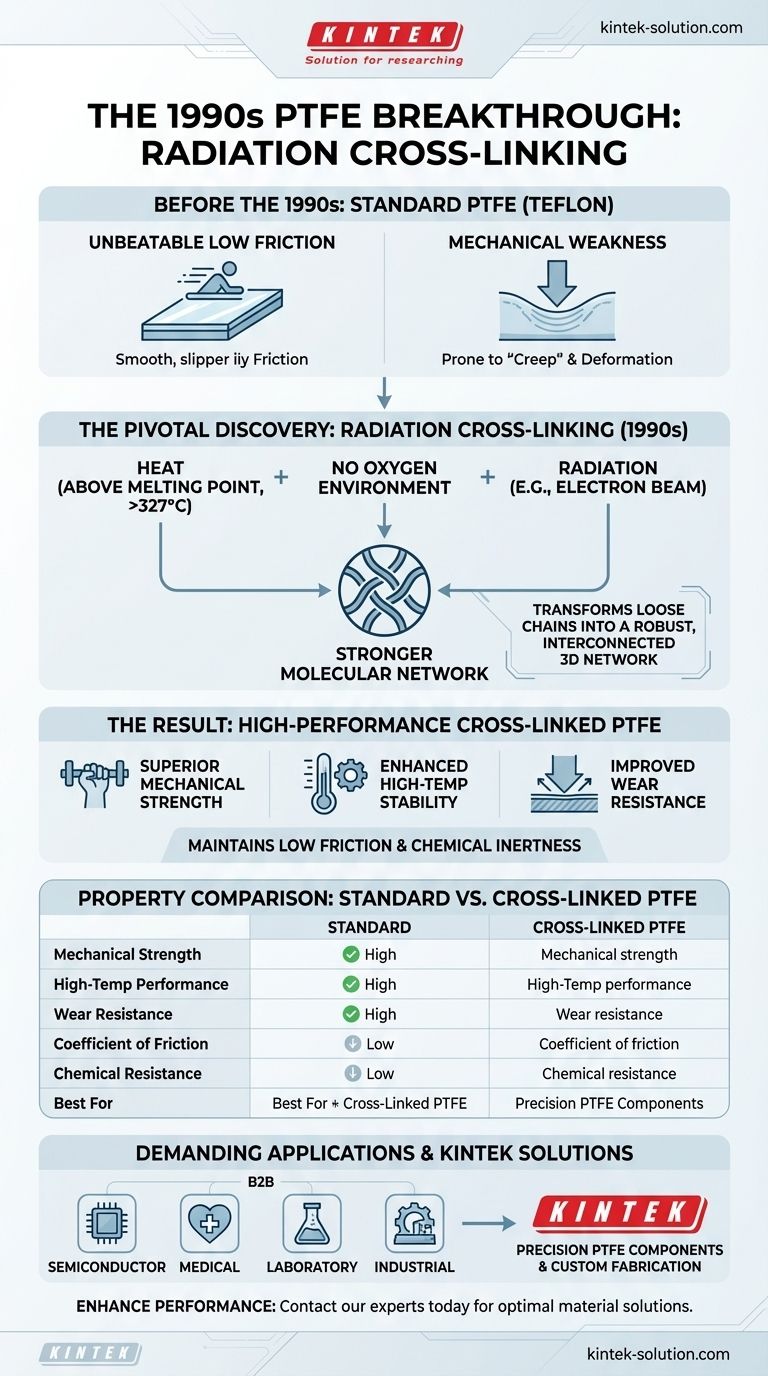

In the 1990s, a pivotal discovery fundamentally changed the capabilities of Polytetrafluoroethylene (PTFE). It was found that PTFE could be radiation cross-linked when processed above its melting point in an oxygen-free environment. This breakthrough allowed for the enhancement of its mechanical properties, overcoming long-standing limitations of the material.

The discovery of radiation cross-linking transformed PTFE from a soft, low-strength material into a robust engineering polymer. This process creates a stronger molecular network, drastically improving high-temperature performance and wear resistance without compromising its famous low-friction surface.

The Challenge with Standard PTFE

Before this discovery, PTFE was known for a specific set of characteristics that made it both incredibly useful and notably limited. Understanding these baseline properties is key to appreciating the impact of the 1990s breakthrough.

An Unbeatable Low-Friction Surface

The most famous property of PTFE is its extremely low coefficient of friction. It is one of the most slippery solid materials known to science.

This non-stick nature comes from its molecular structure, which is highly resistant to the van der Waals forces that cause materials to adhere to one another.

The Problem of Mechanical Weakness

Despite its chemical inertness and slipperiness, standard PTFE is a mechanically soft material. Under load, especially at elevated temperatures, it is prone to "creep," or slow deformation.

This weakness limited its use in applications requiring structural integrity, high loads, or significant wear resistance.

How Radiation Cross-Linking Solves the Problem

The ability to cross-link PTFE chains using radiation, such as an electron beam, directly addresses its mechanical shortcomings.

Creating a Stronger Molecular Network

Cross-linking transforms the individual, spaghetti-like polymer chains of standard PTFE into a single, interconnected three-dimensional network.

Think of it as turning a pile of loose threads into a tightly woven fabric. This new structure is far more resistant to being pulled apart or deformed.

The Critical Processing Conditions

This process only works under very specific conditions discovered in the 1990s: it must be done above PTFE's melting point and in an oxygen-free environment.

Heating above the melting point allows the polymer chains the mobility to link together, while the absence of oxygen prevents the material from degrading under the intense radiation.

The Result: A High-Performance Material

The resulting cross-linked PTFE exhibits vastly improved properties. It has enhanced radiation stability and, most importantly, superior mechanical strength and stability at high temperatures.

This means it can withstand greater loads and higher temperatures without deforming, opening up a new range of demanding industrial and engineering applications.

Understanding the Trade-offs

While cross-linking is a powerful enhancement, it's a specific solution for a specific set of problems. It introduces new considerations into the material selection process.

Increased Cost and Complexity

Radiation cross-linking is an additional, sophisticated manufacturing step. This makes cross-linked PTFE more expensive than standard grades.

Targeted Improvements

The primary benefits are mechanical and thermal. The process does not significantly alter PTFE's fundamental chemical resistance or its low coefficient of friction, which is often a desired outcome.

Not a Universal Replacement

This advanced material is not necessary for every application. For components that do not face high mechanical stress or extreme temperatures, standard PTFE remains a perfectly suitable and more economical choice.

Making the Right Choice for Your Goal

Selecting the correct grade of PTFE depends entirely on the performance demands of your application.

- If your primary focus is low friction and chemical resistance in low-stress environments: Standard, non-cross-linked PTFE remains the most cost-effective and appropriate choice.

- If your application involves high temperatures, significant mechanical loads, or radiation exposure: Cross-linked PTFE is the superior option, providing the durability and creep resistance that standard PTFE lacks.

Understanding this key advancement allows you to select the precise grade of PTFE that meets the demanding requirements of your specific application.

Summary Table:

| Property | Standard PTFE | Radiation Cross-Linked PTFE |

|---|---|---|

| Mechanical Strength | Low (soft, prone to creep) | High (resistant to deformation) |

| High-Temp Performance | Limited | Significantly Improved |

| Wear Resistance | Low | High |

| Coefficient of Friction | Extremely Low | Remains Extremely Low |

| Chemical Resistance | Excellent | Excellent |

| Best For | Low-stress, non-stick applications | High-load, high-temp, demanding environments |

Need the Right PTFE for Your Demanding Application?

Understanding the difference between standard and cross-linked PTFE is critical for the success of your components in the semiconductor, medical, laboratory, and industrial sectors. KINTEK specializes in manufacturing precision PTFE components—from seals and liners to custom labware—and we have the expertise to guide you to the optimal material choice.

We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet the exact mechanical, thermal, and chemical requirements of your application.

Let's discuss your project. Contact our experts today to get a quote and see how our precision PTFE solutions can enhance your product's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Parts Manufacturer PTFE Cleaning Rack

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications