In short, Teflon is added to nail polish to make it tougher and more flexible. This polymer acts as a strengthening agent, creating a more resilient coating on the nail that is significantly less prone to chipping compared to traditional formulas.

The core reason for including Teflon in nail polish is to solve the fundamental problem of brittleness. Its unique properties, borrowed from industrial applications, allow the polish to flex with the natural nail, drastically reducing the cracks and chips that cause manicures to fail.

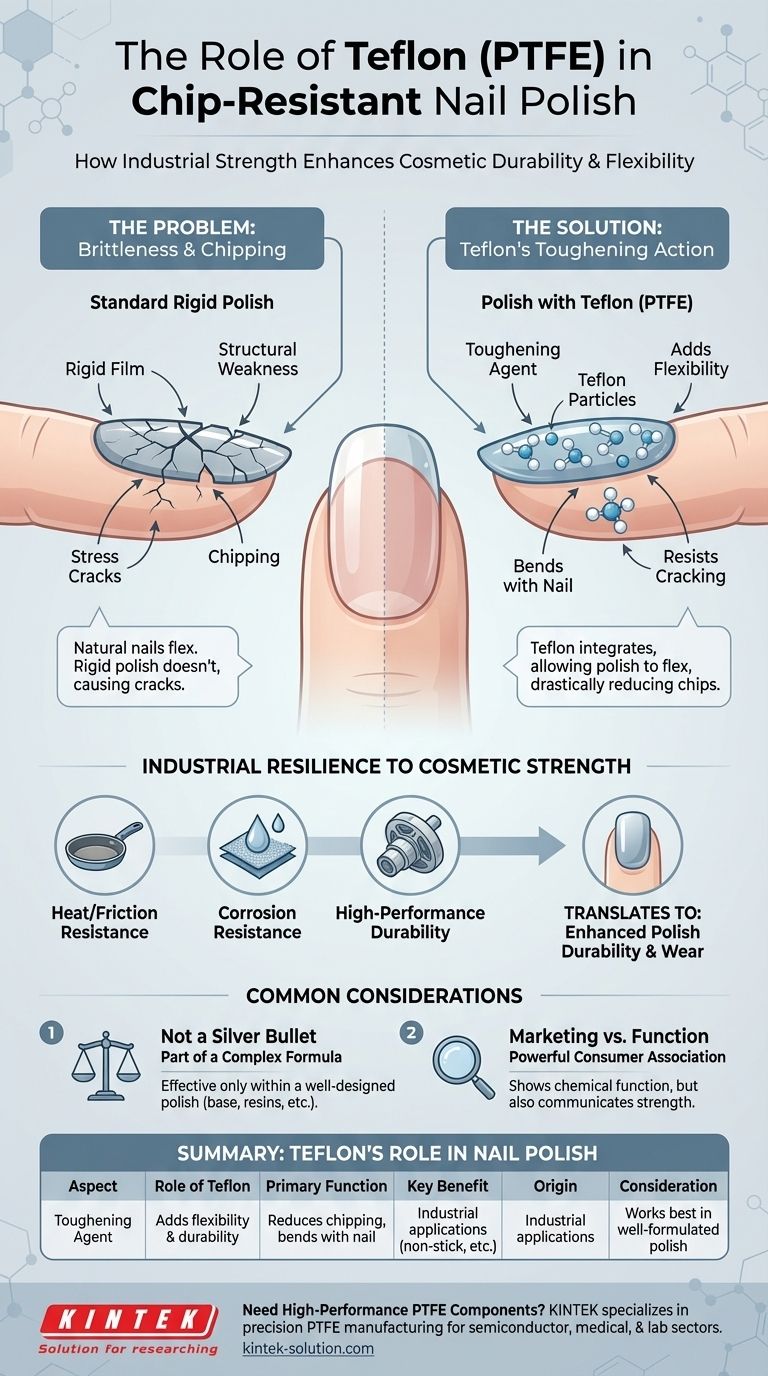

The Core Problem with Nail Polish: Brittleness

Why Nail Polish Chips

Standard nail polish dries into a hard, rigid film. While this provides color and shine, it creates a structural weakness.

Your natural nails are not perfectly rigid; they have a degree of flex. When your nail bends from daily activities, a rigid polish film cannot bend with it. This stress causes microscopic cracks that quickly grow into visible chips.

The Search for a Better Polymer

Cosmetic formulators are constantly searching for ingredients that can improve the performance of nail polish.

The ideal ingredient adds durability and flexibility without compromising on shine, color, or drying time. This is where high-performance polymers from other industries become valuable.

How Teflon Solves the Durability Problem

Acting as a Toughening Agent

Teflon is best understood as a toughening agent in the nail polish formula. It integrates into the polish film, introducing a level of flexibility that wasn't there before.

This allows the dried polish to bend and move with the natural nail instead of cracking under pressure.

Leveraging Industrial-Grade Resilience

Teflon is famous for its use in non-stick cookware, waterproof fabrics, and even aerospace components like heat shields. These applications rely on its exceptional resistance to heat, corrosion, and friction.

While your nails don't face those extreme conditions, these properties translate into a more durable, resilient coating that can better withstand the wear and tear of daily life.

Common Pitfalls to Avoid

Viewing It as a Silver Bullet

While Teflon significantly improves chip resistance, it is only one part of a complex formula. The overall quality of the polish—including its base resins, plasticizers, and solvents—determines the final performance.

A polish containing Teflon can still chip if the rest of the formula is poorly designed.

Confusing Function with Marketing

The name "Teflon" carries a powerful consumer association with durability and non-stick performance. Brands often leverage this name for marketing purposes.

While the ingredient does serve a clear chemical function, its presence on a label is also a signal designed to communicate strength and longevity to the buyer.

Making the Right Choice for Your Goal

Understanding an ingredient's function helps you look past the marketing and focus on performance.

- If your primary focus is a long-lasting manicure: Seek out polishes marketed as "chip-resistant," "long-wear," or "gel-like," as these formulas are engineered with flexible polymers like Teflon to maximize durability.

- If your primary focus is understanding ingredients: Recognize that Teflon is a prime example of how cosmetic science borrows high-performance materials from other industries to solve common frustrations.

By understanding the "why" behind an ingredient, you can make more informed decisions about the products you choose.

Summary Table:

| Aspect | Role of Teflon |

|---|---|

| Primary Function | Acts as a toughening agent for flexibility and durability |

| Key Benefit | Reduces chipping by allowing polish to bend with the nail |

| Origin | Borrowed from industrial applications (e.g., non-stick coatings) |

| Consideration | Works best as part of a well-formulated polish, not a standalone fix |

Need High-Performance PTFE Components for Your Industry?

At KINTEK, we specialize in precision PTFE manufacturing—from seals and liners to custom labware—for sectors like semiconductor, medical, and laboratory industries. Whether you require prototypes or high-volume orders, our expertise ensures durable, flexible solutions tailored to your needs.

Contact us today to discuss how our PTFE components can enhance your products' performance and reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications