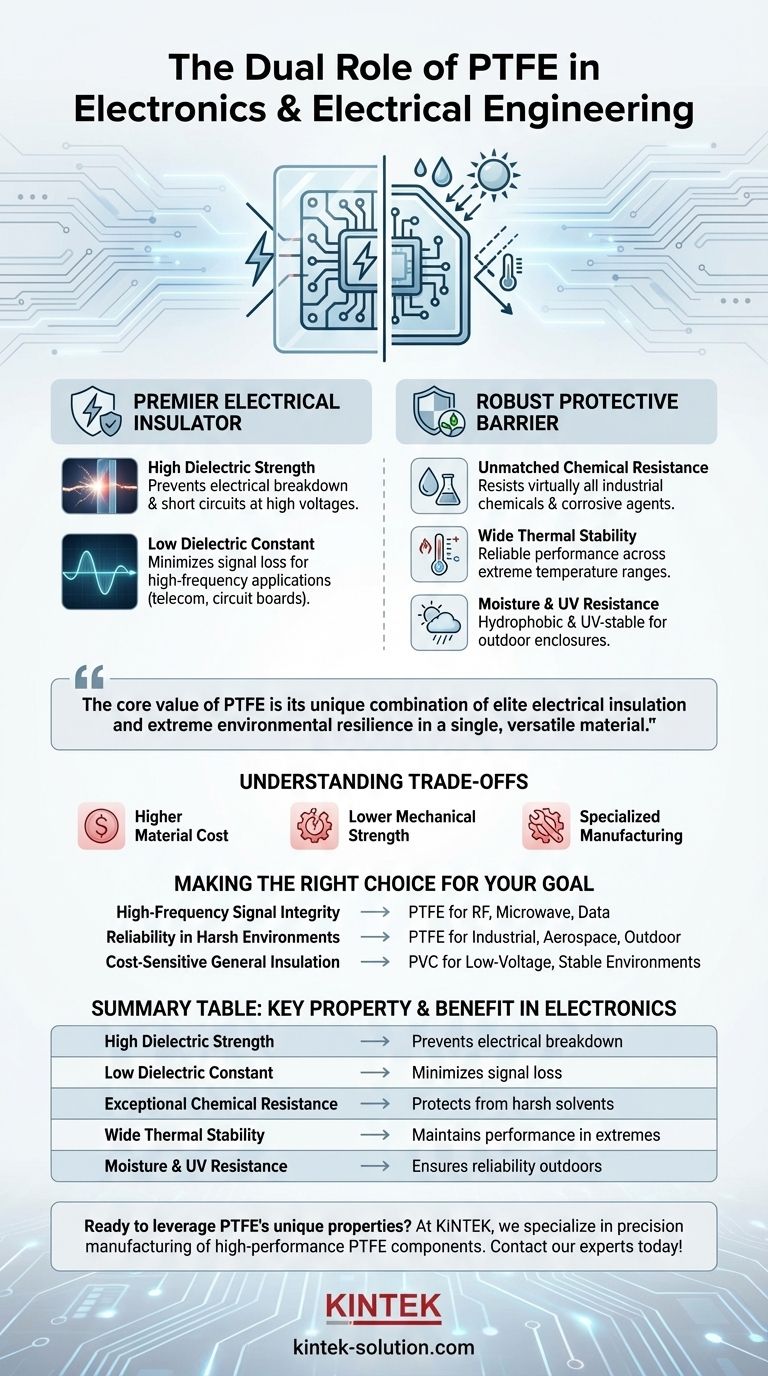

In the field of electronics and electrical engineering, Polytetrafluoroethylene (PTFE) serves a critical dual function. It is a premier electrical insulator prized for its ability to prevent electrical current leakage, even at high voltages. Simultaneously, it acts as a robust protective barrier, shielding sensitive components from heat, chemicals, and moisture to ensure long-term reliability.

The core value of PTFE in electronics is not just one feature, but its unique combination of properties. It provides elite electrical insulation and extreme environmental resilience in a single, versatile material, making it indispensable for high-performance and mission-critical applications.

The Core Electrical Properties of PTFE

The primary reason PTFE is specified in electrical design is its outstanding performance as an insulator. Its molecular structure gives it properties that are highly desirable for managing electrical energy.

Superior Electrical Insulation

PTFE has an extremely high dielectric strength, which is a material's ability to withstand a strong electric field without breaking down and becoming conductive.

This makes it an ideal material for insulating high-voltage wiring, cable jackets, and connectors, effectively preventing short circuits and ensuring operational safety.

Low Dielectric Constant

For high-frequency applications, such as those in telecommunications and circuit boards, PTFE's low dielectric constant is critical.

This property means the material stores very little electrical energy. In practice, this minimizes signal loss and distortion, preserving the integrity of data being transmitted through cables or across a circuit board.

A Shield Against Environmental Stress

Beyond its electrical characteristics, PTFE provides unparalleled protection against the physical and chemical hazards that electronic components often face. This ensures the longevity and reliability of the device.

Unmatched Chemical Resistance

As a fluorocarbon polymer, PTFE is almost completely inert. It resists degradation from virtually all industrial chemicals, solvents, and corrosive agents.

This makes it essential for gaskets and seals in equipment that may be exposed to harsh chemical environments, protecting sensitive internal electronics from damage.

Wide Thermal Stability

PTFE components perform reliably across an exceptionally wide temperature range.

This stability ensures that its insulating and protective properties do not degrade in applications that experience extreme heat, such as in engine bays, or the cold of aerospace environments.

Resistance to Moisture and UV

The material is hydrophobic (repels water) and is not degraded by UV radiation from sunlight. This makes it a perfect choice for outdoor electrical enclosures, connectors, and cable jackets that must endure the elements without failing.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the default choice for every application. Acknowledging its limitations is key to making sound engineering decisions.

Higher Material Cost

PTFE is a premium performance polymer. Its cost is significantly higher than that of common insulators like PVC or polyethylene. Its use is typically justified by performance requirements, not budget constraints.

Lower Mechanical Strength

Compared to other engineering plastics, PTFE is relatively soft and has poor resistance to wear and abrasion. It is also susceptible to "creep," a tendency to deform slowly under a sustained load. It is not intended for use as a structural component.

Specialized Manufacturing

Processing and machining PTFE requires specific expertise and tools. It cannot be processed with the same ease as many commodity plastics, which can add to the final component cost and lead time.

Making the Right Choice for Your Goal

Selecting the right material always depends on the primary objective of your design. PTFE is the clear choice for performance, but other materials may suffice for less demanding roles.

- If your primary focus is high-frequency signal integrity: PTFE is the industry standard for RF, microwave, and high-speed data applications due to its low dielectric constant.

- If your primary focus is reliability in harsh environments: The unmatched chemical, thermal, and UV resistance of PTFE makes it the definitive choice for industrial, aerospace, or outdoor electronics.

- If your primary focus is cost-sensitive general insulation: For standard, low-voltage applications in stable environments, more economical insulators like PVC will likely meet the required specifications.

Ultimately, leveraging PTFE's unique balance of electrical and protective properties allows engineers to build more resilient and higher-performing electronic systems.

Summary Table:

| Key Property | Benefit in Electronics |

|---|---|

| High Dielectric Strength | Prevents electrical breakdown and short circuits, even at high voltages. |

| Low Dielectric Constant | Minimizes signal loss and distortion in high-frequency applications (RF, microwave). |

| Exceptional Chemical Resistance | Protects components from harsh solvents and corrosive agents. |

| Wide Thermal Stability | Maintains performance across extreme temperature ranges. |

| Moisture & UV Resistance | Ensures reliability for outdoor and demanding environmental applications. |

Ready to leverage PTFE's unique properties in your next project?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—from custom seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your components meet the highest standards for electrical insulation and environmental resilience.

Contact our experts today to discuss your specific requirements and discover how our custom PTFE solutions can enhance the reliability and performance of your electronic designs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments