In automotive manufacturing, Polytetrafluoroethylene (PTFE) is a critical high-performance fluoropolymer used to enhance vehicle durability, efficiency, and reliability. It serves key functions in reducing friction between moving parts, sealing systems against leaks, and resisting extreme temperatures and corrosive chemicals. Common applications include coatings, seals, gaskets, and linings for fuel and power steering hoses.

The core value of PTFE in the automotive industry is not merely as a material, but as a problem-solver. Its unique combination of near-zero friction, extreme temperature stability, and chemical inertness allows engineers to solve fundamental challenges related to wear, heat, and fluid corrosion, leading to longer-lasting and more efficient vehicles.

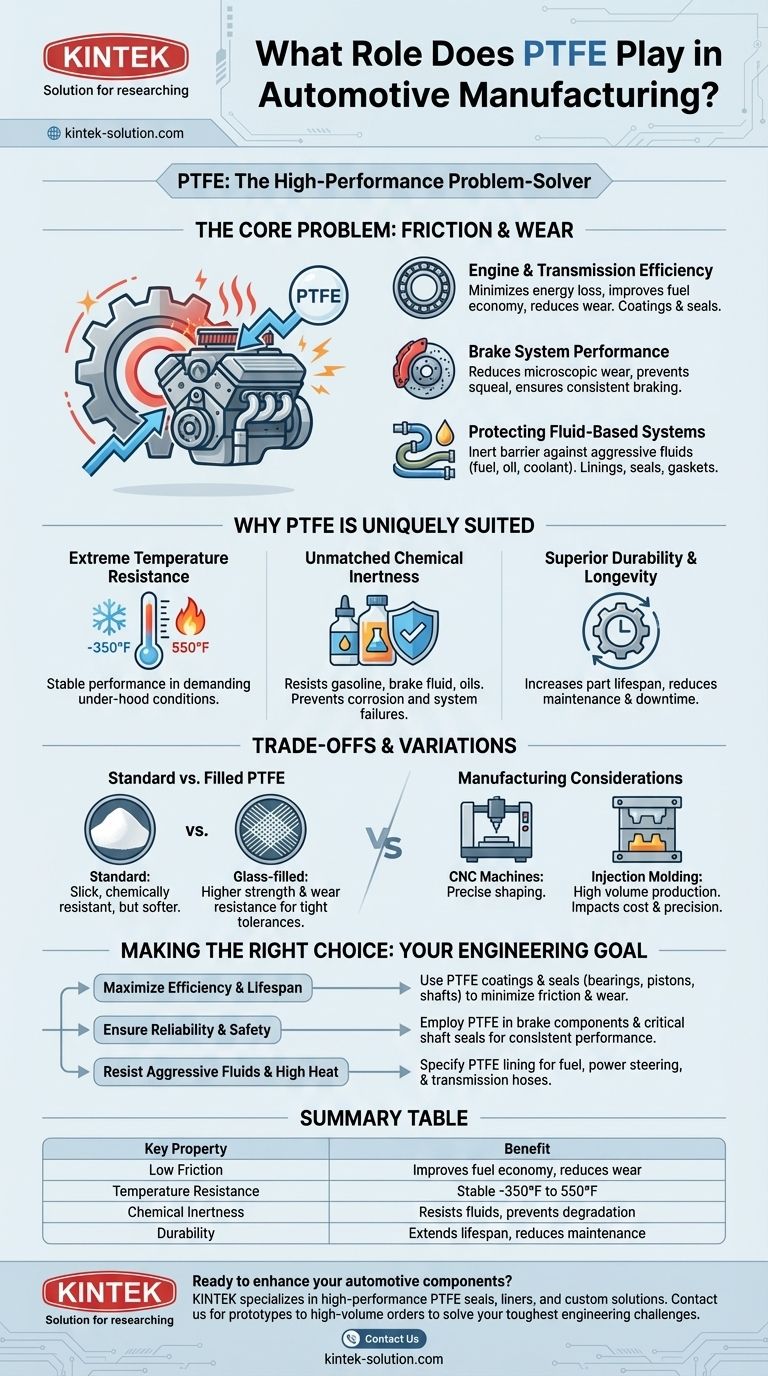

The Core Problem PTFE Solves: Friction and Wear

Modern vehicles operate under immense stress, where friction and wear are constant enemies of performance and longevity. PTFE directly counteracts these forces in several critical systems.

Enhancing Engine and Transmission Efficiency

Components like bearings, O-rings, and shaft seals are often coated with or made from PTFE. Its incredibly low coefficient of friction minimizes the energy lost between moving parts.

This reduction in friction translates directly to improved fuel economy and less wear on critical engine and transmission components over the vehicle's lifespan.

Improving Brake System Performance

PTFE is used in brake systems to reduce the microscopic wear that can cause operational issues.

By ensuring smoother engagement and release of components, it helps prevent common problems like brake squeal and contributes to more consistent, reliable braking performance.

Protecting Fluid-Based Systems

PTFE's chemical resistance makes it the ideal material for lining fuel hoses, power steering lines, and transmission fluid conduits.

It creates an inert barrier that prevents aggressive fluids from degrading the hose material, ensuring the integrity and safety of these vital systems. Common components include valve stem seals and gaskets.

Why PTFE is Uniquely Suited for Automotive Use

PTFE is not chosen by accident. Its fundamental molecular structure, created through the polymerization of tetrafluoroethylene, gives it a set of properties that are almost perfectly matched to the demands of an automotive environment.

Extreme Temperature Resistance

Automotive components must function flawlessly from a cold start to peak operating temperatures.

PTFE maintains its integrity and performance characteristics across a vast temperature range, typically from -350°F to 550°F (-212°C to 287°C), making it stable in even the most demanding under-hood conditions.

Unmatched Chemical Inertness

A vehicle relies on numerous aggressive fluids, including gasoline, brake fluid, coolant, and oils.

PTFE is almost completely inert and non-reactive, ensuring it will not corrode or degrade when exposed to these chemicals. This safeguards equipment and prevents catastrophic system failures.

Superior Durability and Longevity

By applying PTFE coatings to parts like screws and bearings, manufacturers significantly increase their lifespan.

This resistance to wear and corrosion leads to more durable parts, which in turn reduces long-term maintenance needs and manufacturing downtime.

Understanding the Trade-offs and Variations

While PTFE is highly effective, selecting the right type and understanding its limitations is critical for successful implementation.

Standard PTFE vs. Filled PTFE

Standard, pure PTFE is exceptionally slick and chemically resistant, but it can be mechanically soft.

For applications requiring higher strength and wear resistance, such as automotive parts with tight tolerances, glass-filled PTFE is often used. The glass fibers add rigidity and durability without significantly compromising PTFE's core benefits.

Manufacturing Considerations

PTFE's properties also influence how it can be formed into parts. It can be precisely shaped using CNC machines or, for higher volume production, processed with specialized injection molding techniques.

The choice of manufacturing method impacts the final cost, precision, and suitability of the component for its intended application.

Making the Right Choice for Your Application

Selecting the right PTFE application depends entirely on your primary engineering goal.

- If your primary focus is maximizing engine efficiency and lifespan: Utilize PTFE coatings and seals for bearings, pistons, and shafts to minimize frictional losses and component wear.

- If your primary focus is ensuring system reliability and safety: Employ PTFE in brake system components and critical shaft seals to guarantee consistent performance and prevent premature failure.

- If your primary focus is resisting aggressive fluids and high heat: Specify PTFE as the lining material for fuel, power steering, and transmission hoses to prevent chemical degradation and ensure long-term integrity.

Ultimately, integrating PTFE is a strategic engineering decision to build more durable, efficient, and reliable vehicles from the inside out.

Summary Table:

| Key Property | Benefit in Automotive Manufacturing |

|---|---|

| Low Friction | Improves fuel economy and reduces wear on engine/transmission parts |

| Temperature Resistance | Stable from -350°F to 550°F, ideal for under-hood conditions |

| Chemical Inertness | Resists gasoline, brake fluid, oils; prevents system degradation |

| Durability | Extends part lifespan, reduces maintenance and downtime |

Ready to enhance your automotive components with precision-engineered PTFE solutions? KINTEK specializes in manufacturing high-performance PTFE seals, liners, and custom components for the automotive industry. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts meet exact specifications for durability, efficiency, and reliability. Contact us today to discuss how our PTFE solutions can solve your toughest engineering challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers