In short, Polytetrafluoroethylene (PTFE) gaskets are essential sealing components chosen for medical and pharmaceutical applications where absolute purity and safety are non-negotiable. They are used as miniature seals in devices like catheters and implantables, and as durable, non-contaminating seals in drug manufacturing equipment to prevent product contamination and process failure.

The core reason PTFE is the material of choice is its unique combination of biological inertness and extreme chemical resistance. This ensures the gasket will never react with the human body, compromise the integrity of a drug, or degrade during harsh sterilization processes.

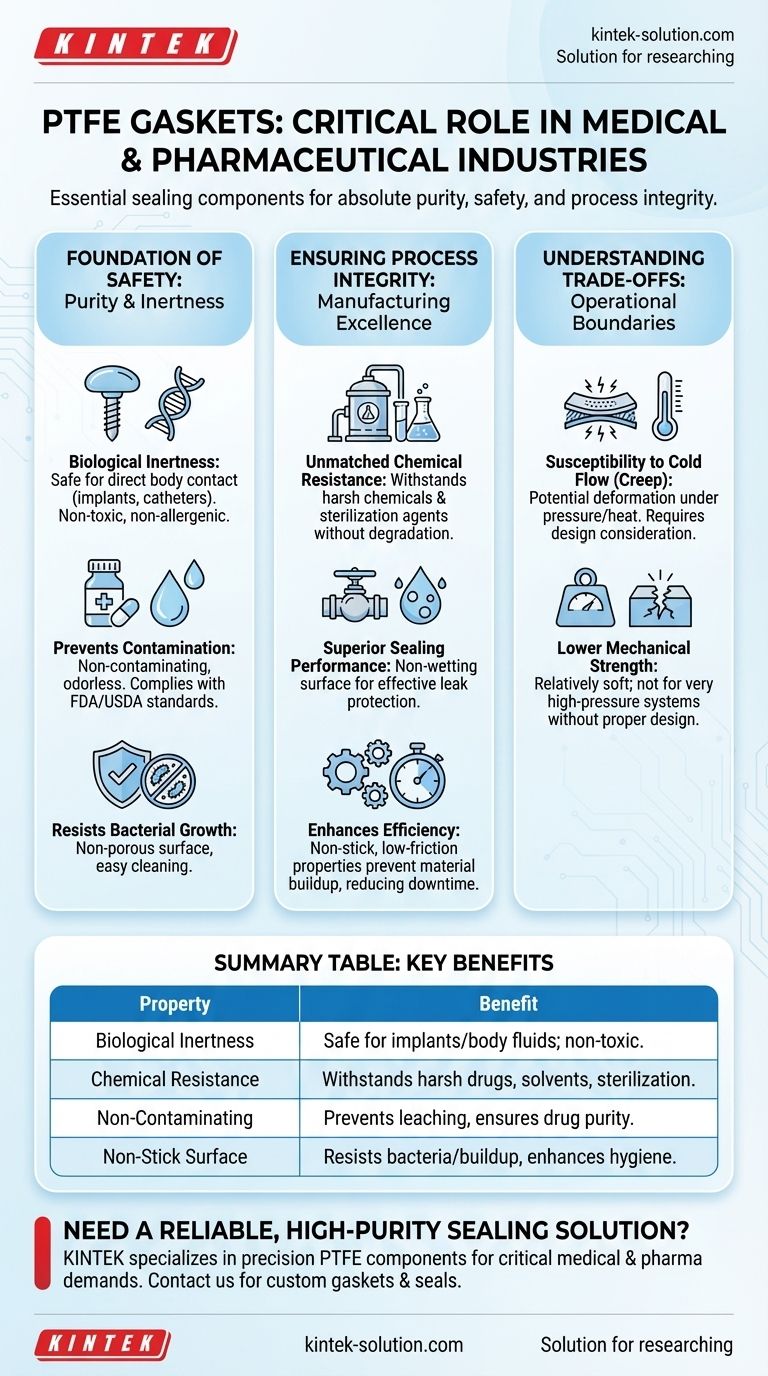

The Foundation of Safety: Why Material Purity Matters

In medical and pharmaceutical contexts, the material of a seal is just as critical as the product it protects. Any interaction between the gasket and its environment can have severe consequences.

Biological Inertness for Medical Devices

PTFE is biologically inert, meaning it does not react with human tissue or fluids. This makes it an ideal material for components that come into direct contact with the body.

Because it is non-toxic, non-allergenic, and non-carcinogenic, it is widely trusted for use in implantables, surgical grafts, and catheters where patient safety is the primary concern.

Preventing Product Contamination

During pharmaceutical manufacturing, maintaining product purity is paramount. PTFE gaskets are non-contaminating and odorless, ensuring they do not leach any substances into the drug product.

This property is a key reason they comply with stringent FDA/USDA standards, which are required for any material used in food and drug processing equipment.

Resistance to Bacterial Growth

The non-stick, non-porous surface of PTFE is naturally resistant to bacterial buildup.

This, combined with its ease of cleaning, helps manufacturers maintain the strict hygiene standards required to prevent contamination and ensure product safety.

Ensuring Process Integrity in Manufacturing

Beyond its inert properties, PTFE provides the physical resilience and performance needed to maintain an efficient and reliable manufacturing process.

Unmatched Chemical Resistance

Pharmaceutical production often involves aggressive chemicals and acids. PTFE is non-corrosive and non-reactive, capable of withstanding these harsh substances without degrading.

This inertness also applies to aggressive cleaning agents used during equipment sterilization, ensuring the gasket maintains its integrity through repeated cycles.

Superior Sealing Performance

A key physical property of PTFE is that it is non-wetting. This means that liquids bead up on its surface rather than spreading, which creates a more effective and reliable seal against leaks.

This quality provides superior protection against cross-contamination between batches and prevents the loss of valuable product.

Enhancing Production Efficiency

PTFE's signature non-stick and low-friction properties are highly beneficial in processing equipment like hoppers and mixers.

These characteristics prevent materials from building up on component surfaces, which enhances production efficiency and reduces downtime for cleaning.

Understanding the Trade-offs

While PTFE's properties make it exceptional for these applications, no material is without limitations. Objectivity requires acknowledging its specific operational boundaries.

Susceptibility to Cold Flow (Creep)

Under sustained mechanical pressure, especially at elevated temperatures, PTFE can be prone to "creep" or "cold flow," where the material slowly deforms over time.

This can potentially compromise the long-term integrity of a seal if not accounted for in the engineering design. In such cases, filled or modified PTFE grades are often used to enhance creep resistance.

Lower Mechanical Strength

Compared to metals or harder plastics, PTFE is a relatively soft material. In very high-pressure systems, a standard PTFE gasket may not be sufficient.

The component design must carefully consider the pressure and temperature requirements to ensure the gasket is not physically extruded from its housing.

Making the Right Choice for Your Application

Selecting the right sealing material depends entirely on the specific demands of the environment.

- If your primary focus is direct patient contact (implants, catheters): The key factor is PTFE's proven biological inertness and compliance with FDA safety standards.

- If your primary focus is pharmaceutical manufacturing (reactors, piping): The combination of chemical non-reactivity and non-contaminating properties is critical for protecting product purity.

- If your primary focus is process efficiency and hygiene: PTFE's non-stick surface prevents material buildup and resists bacterial growth, simplifying cleaning and maximizing uptime.

Ultimately, selecting PTFE is a decision to prioritize uncompromising safety, purity, and reliability in the most critical environments.

Summary Table:

| Property | Benefit for Medical/Pharma |

|---|---|

| Biological Inertness | Safe for implants and contact with bodily fluids; non-toxic and non-allergenic. |

| Chemical Resistance | Withstands harsh drugs, solvents, and sterilization agents without degrading. |

| Non-Contaminating | Prevents leaching, ensuring drug purity and compliance with FDA/USDA standards. |

| Non-Stick Surface | Resists bacterial growth and material buildup, enhancing hygiene and efficiency. |

Need a reliable, high-purity sealing solution?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom gaskets, seals, and labware. We understand the critical demands of the semiconductor, medical, and pharmaceutical industries. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component that guarantees safety, prevents contamination, and enhances your process efficiency.

Contact us today to discuss your specific application requirements and learn how our PTFE solutions can protect your products and processes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability