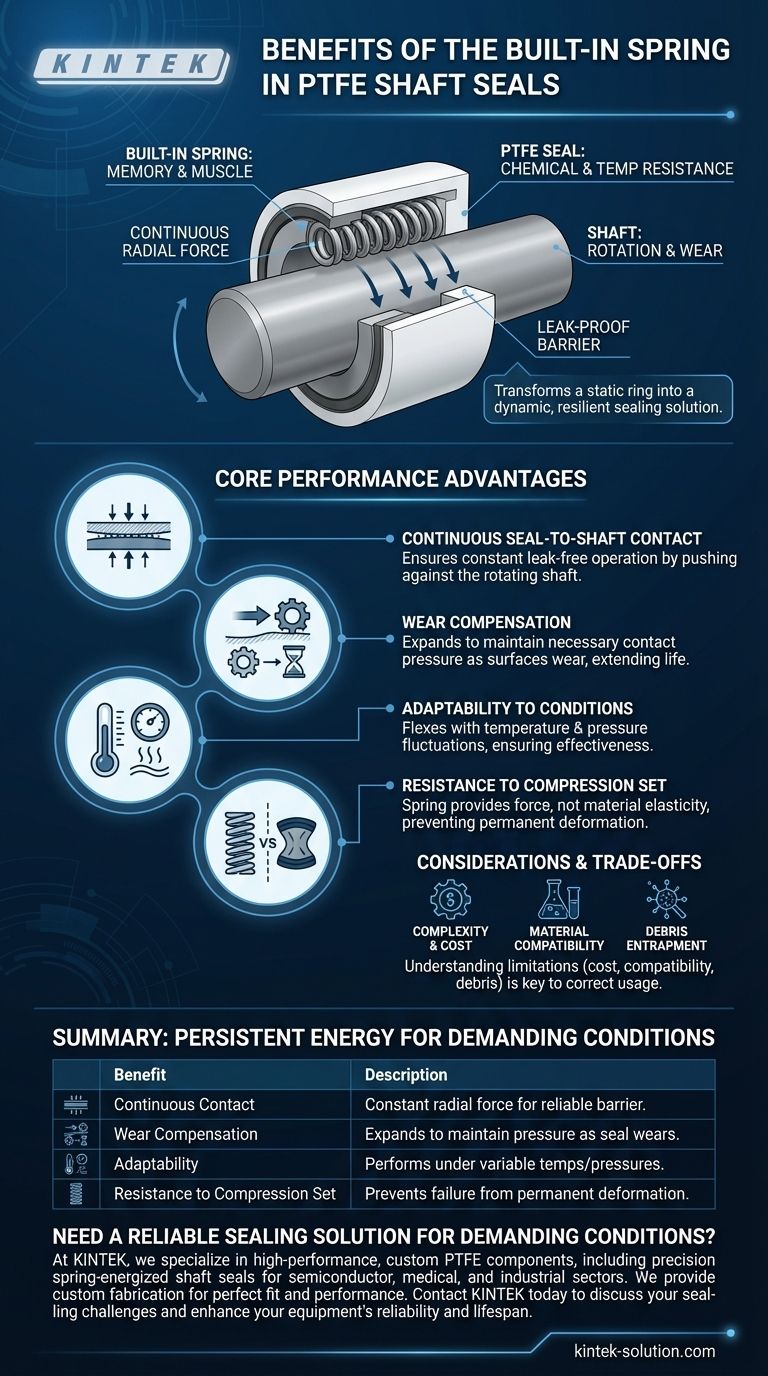

The built-in spring is the critical component that transforms a PTFE shaft seal from a static ring into a dynamic, resilient sealing solution. It provides the continuous, live energy needed to ensure constant seal-to-shaft contact, compensate for wear over the seal's lifespan, and maintain performance across a wide range of demanding operating conditions.

The core function of the spring is to provide the consistent mechanical force that the high-performance PTFE material inherently lacks. It acts as the "memory" and "muscle" of the seal, ensuring it remains effective long after a simple elastomeric or non-energized seal would fail.

The Spring's Fundamental Role: Consistent Radial Force

The primary job of any shaft seal is to create a reliable barrier between two environments. The spring is the mechanism that guarantees this barrier remains intact under real-world pressures.

Ensuring Continuous Seal-to-Shaft Contact

At its most basic level, the spring—typically made of a corrosion-resistant metal like stainless steel—exerts a constant radial force on the PTFE sealing lip. This force pushes the lip firmly against the rotating shaft, closing any microscopic gaps that could lead to leaks.

Overcoming the Limits of PTFE

While PTFE is an exceptional material with a low friction coefficient and superior chemical and temperature resistance, it is not an elastomer like rubber. It has poor "memory" and is susceptible to compression set, meaning it can permanently deform and fail to bounce back after being compressed. The spring provides the energy the PTFE lacks, ensuring the sealing lip never loses contact.

Key Performance Benefits Enabled by the Spring

By providing this constant, dynamic force, the spring unlocks several critical performance advantages that define the value of these seals in demanding applications.

Compensating for Inevitable Wear

As the seal and shaft operate, friction causes microscopic material loss on both surfaces. A non-energized seal would quickly lose its preload and begin to leak. The spring, however, expands to "follow" the receding surface, maintaining the necessary contact pressure and dramatically extending the seal's effective operational life.

Adapting to Variable Operating Conditions

Industrial equipment rarely operates in a perfectly stable state. The spring allows the seal to adapt to fluctuations in temperature, which cause materials to expand and contract, as well as variations in system pressure. This dynamic response ensures the seal remains effective even when conditions are not ideal.

Eliminating Failure from Compression Set

Because the sealing force is generated by the mechanical spring rather than the material's elasticity, the seal is not vulnerable to compression set. This makes it exceptionally reliable in applications involving pressure cycles or thermal cycling, where a traditional rubber seal would quickly fatigue and fail.

Understanding the Trade-offs

While highly effective, spring-energized seals are a specific engineering solution with their own set of considerations. Understanding their limitations is key to using them correctly.

Increased Complexity and Cost

The multi-component design (PTFE jacket and metal spring) is inherently more complex and costly to manufacture than a simple elastomeric lip seal. This investment is justified only when the performance demands of the application require it.

Material Compatibility of All Components

An engineer must consider the chemical and thermal compatibility of both the PTFE jacket and the spring material. In a highly corrosive environment, a standard stainless steel spring could fail even if the PTFE jacket remains unaffected.

Potential for Debris Entrapment

The cavity that houses the spring can potentially trap process media, particulates, or other debris. In sanitary, food-grade, or clean-room applications, this can be a significant design concern that requires careful consideration.

Making the Right Choice for Your Application

Selecting the right seal depends entirely on the specific demands of your equipment and process.

- If your primary focus is maximum service life in a high-wear environment: The spring's ability to compensate for material loss is the most critical benefit.

- If your primary focus is reliability under fluctuating temperatures or pressures: The dynamic response provided by the spring makes it the superior choice over a standard seal.

- If your primary focus is sealing a simple, low-speed application in a stable environment: A less complex and more cost-effective elastomeric seal may be the more appropriate solution.

Ultimately, understanding that the spring provides the persistent energy for the seal is key to deploying this technology where it can deliver the most value.

Summary Table:

| Benefit | Description |

|---|---|

| Continuous Contact | Provides constant radial force for a reliable leak-proof barrier. |

| Wear Compensation | Expands to maintain contact pressure as the seal and shaft wear. |

| Adaptability | Allows the seal to perform under variable temperatures and pressures. |

| Resistance to Compression Set | Seal force comes from the spring, not material elasticity, preventing failure. |

Need a reliable sealing solution for demanding conditions?

At KINTEK, we specialize in manufacturing high-performance, custom PTFE components, including precision spring-energized shaft seals. Our seals are engineered for the semiconductor, medical, laboratory, and industrial sectors, where reliability under pressure, temperature fluctuations, and corrosive environments is non-negotiable.

We provide custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and optimal performance for your specific application.

Contact KINTEK today to discuss your sealing challenges and discover how our precision PTFE components can enhance your equipment's reliability and lifespan.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications