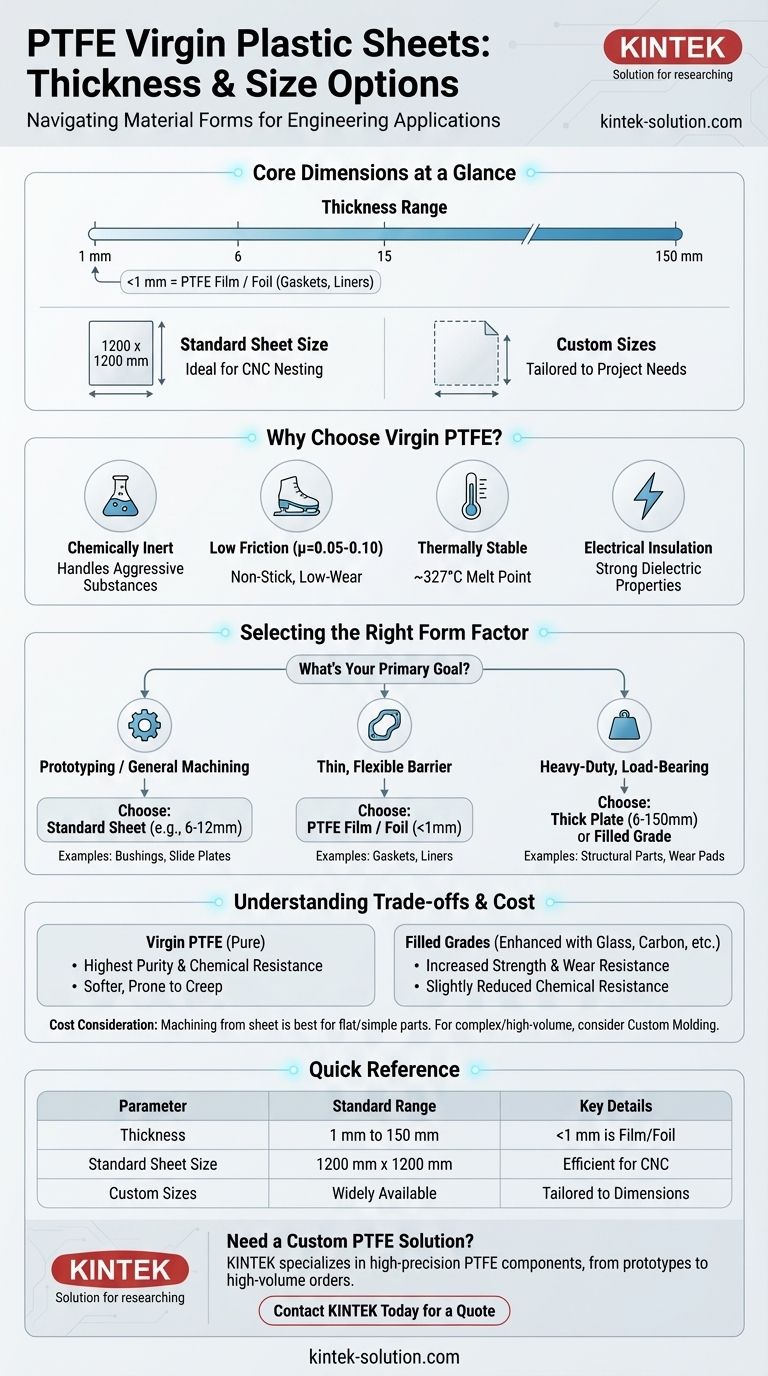

At its core, virgin PTFE plastic sheets are available in a broad spectrum of thicknesses, commonly ranging from 1 mm up to 150 mm. The most standard industrial sheet size is 1200x1200 mm, but custom dimensions are widely available from suppliers to meet specific project needs. For applications requiring less than 1 mm of thickness, the material is typically categorized as a PTFE film or foil.

The specific dimensions of a PTFE sheet are less important than understanding why you are choosing that form factor. The real decision involves balancing the unique properties of virgin PTFE against the requirements of your application to determine if a sheet, a film, or a custom-molded part is the most effective solution.

Why Choose Virgin PTFE?

Before selecting a size, it's crucial to understand what "virgin" PTFE offers. This designation means the material is pure, unfilled Polytetrafluoroethylene, giving it a distinct set of baseline properties.

The Defining Characteristics

Virgin PTFE is renowned for its extreme performance. It is one of the most chemically inert plastics available, making it invaluable for handling aggressive substances.

Its coefficient of friction is exceptionally low (0.05-0.10), comparable to wet ice on wet ice. This delivers a superior non-stick, low-wear surface.

The material also boasts excellent thermal stability, with a melting point around 327°C (621°F), and strong electrical insulation properties.

Navigating Sheet Dimensions

With an understanding of the material's benefits, you can now effectively choose the right dimensions for your job. The available options are designed to serve distinct engineering purposes.

Common Thickness Options

For most general fabrication and machining, standard off-the-shelf thicknesses are the most economical choice. These typically include:

- 1 mm, 2 mm, 3 mm

- 5 mm, 6 mm, 8 mm

- 10 mm, 12 mm, 15 mm

- 20 mm, 25 mm, and up

These sizes are ideal for creating bushings, insulators, slide plates, and other machined components.

Thick Plates vs. Thin Films

A critical distinction exists based on thickness. Material below 1 mm is generally classified as PTFE film or foil, used for thin gaskets, liners, and flexible barriers.

Material from approximately 6 mm to 150 mm is considered a thick plate. These are intended for heavy-duty structural components, large wear pads, or parts that require significant material to be machined away.

Standard and Custom Sizes

The industry standard sheet size is 1200x1200 mm. This large format is efficient for nesting multiple parts to minimize waste during CNC machining.

However, almost all suppliers offer custom cutting services. You can request specific lengths and widths, which is ideal for one-off projects or unique geometries, though it may come at a higher per-unit cost.

Understanding the Trade-offs

While virgin PTFE is a powerful material, it is not a universal solution. Understanding its limitations is key to avoiding project failures.

Virgin vs. Filled Grades

Virgin PTFE offers the highest purity and chemical resistance. However, it is relatively soft and can be subject to "creep" or deformation under a sustained load.

For applications requiring higher compressive strength or wear resistance, consider filled PTFE grades. Fillers like glass, carbon, or bronze are added to enhance specific mechanical properties, though this may slightly reduce chemical resistance or change its electrical properties.

The Cost of Form Factor

A standard sheet is the raw material. The final cost of your part will be heavily influenced by machining complexity. For intricate or high-volume parts, it may be more economical to investigate custom molding or extrusion rather than machining from a solid sheet.

When to Choose a Sheet

A PTFE sheet is the right choice when you need to create a flat component (like a slide plate) or machine a three-dimensional part from a solid block. If your application is a simple sleeve or rod, buying that specific shape from the start will be far more efficient than machining it from a large sheet.

Making the Right Choice for Your Application

Selecting the correct PTFE format comes down to your primary goal.

- If your primary focus is general prototyping or machining: Start with a common thickness like 6 mm or 12 mm in a standard or custom-cut sheet to balance cost and versatility.

- If your primary focus is creating a thin, flexible gasket or liner: Your search should be for PTFE film or foil, not sheets, to get the right flexibility and thickness.

- If your primary focus is a heavy-duty, load-bearing component: Specify a thick PTFE plate and be prepared for the associated material and machining costs, or investigate a suitable filled PTFE grade.

Ultimately, aligning the material's form factor with your specific design requirements is the key to leveraging the powerful properties of PTFE effectively.

Summary Table:

| Parameter | Standard Range | Key Details |

|---|---|---|

| Thickness | 1 mm to 150 mm | <1 mm is classified as film/foil |

| Standard Sheet Size | 1200 mm x 1200 mm | Ideal for efficient CNC machining |

| Custom Sizes | Widely Available | Tailored to specific project dimensions |

Need a custom PTFE solution?

KINTEK specializes in manufacturing high-precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your project benefits from the superior chemical resistance and thermal stability of virgin PTFE.

Contact KINTEK today to discuss your specifications and get a quote tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts