From a technical standpoint, the operational advantages of PTFE slide bearings in construction are centered on their unique combination of an extremely low coefficient of friction, high load capacity, and complete resistance to environmental degradation. This allows them to provide a maintenance-free, highly durable, and cost-effective solution for managing structural movement over a building's entire lifespan.

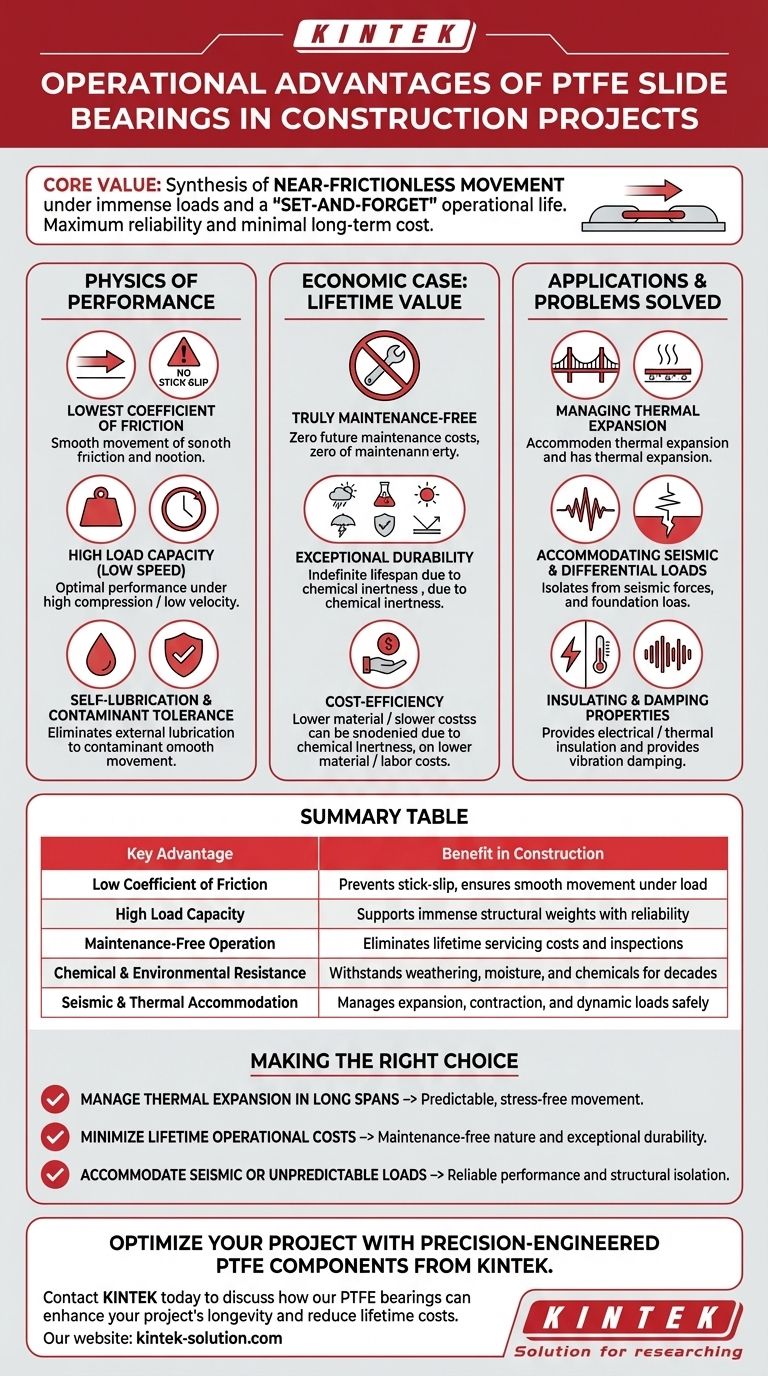

The core value of PTFE slide bearings is not a single feature, but their synthesis of near-frictionless movement under immense loads and a "set-and-forget" operational life. This makes them a default solution for managing structural forces with maximum reliability and minimal long-term cost.

The Physics of Performance: Why PTFE Excels

The material properties of Polytetrafluoroethylene (PTFE) are the foundation of its advantages as a bearing surface in demanding construction environments.

The Lowest Coefficient of Friction

PTFE possesses one of the lowest coefficients of friction of any solid material. This ensures smooth, predictable movement between structural elements.

Crucially, this property prevents stick-slip action, a hazardous cycle of static friction buildup and sudden release that can impart damaging shock loads into a structure.

High Load Capacity at Low Speeds

These bearings are engineered to perform optimally under conditions of high compressive load and low velocity. This is the exact scenario found in most structural applications, like the slow thermal expansion of a bridge deck.

Self-Lubrication and Contaminant Tolerance

PTFE is inherently self-lubricating, eliminating the need for grease or any external lubrication that could attract contaminants or degrade over time.

Its surface can also absorb small dirt or dust particles, preventing them from scoring the mating surface and compromising performance.

The Economic Case: Lifetime Value and Reliability

The financial and operational benefits of PTFE slide bearings extend far beyond their initial purchase price, focusing on total cost of ownership.

Truly Maintenance-Free Operation

Once properly installed, PTFE bearings are designed to function for the life of the structure with zero required maintenance.

This eliminates all future costs and logistical challenges associated with inspection, lubrication, and replacement of bearing components.

Exceptional Durability and Lifespan

Due to its chemical inertness, PTFE is completely unaffected by weathering, UV radiation, moisture, and common industrial chemicals. This grants it a virtually indefinite operational life.

It also acts as an insulator, preventing the galvanic corrosion that can occur when dissimilar metals are in contact.

Cost-Efficiency Through Simplicity

The inherent simplicity of a slide bearing design makes them easy to fabricate and install. This straightforwardness reduces both material and labor costs compared to more complex mechanical bearing assemblies.

Applications and Problems Solved

PTFE slide bearings are not a general-purpose component; they are a specific solution for managing large-scale structural forces and movements.

Managing Thermal Expansion

Their primary role is to accommodate the thermal expansion and contraction of large structures like long-span bridges, pipelines, and commercial buildings. The low friction allows these elements to move freely without building up destructive internal stresses.

Accommodating Seismic and Differential Loads

In addition to thermal cycles, these bearings manage movements from seismic activity, wind loads, and the differential settlement of foundations. They provide a reliable slip plane that isolates and protects the primary structure from these forces.

Insulating and Damping Properties

As a non-conductor, PTFE provides excellent electrical and thermal insulation between components. It also offers a degree of vibration damping, which can help reduce noise and fatigue in the overall structure.

Understanding the Trade-offs and Installation Realities

While highly effective, the performance of PTFE bearings is contingent on proper design and installation.

High Load, Low Speed Dependency

The ideal performance of PTFE is locked to high-load, low-speed applications. They are not suitable for high-speed rotational uses, where different wear and thermal dynamics are at play.

The Criticality of Mating Surfaces

The effectiveness of the bearing is equally dependent on the mating surface, which is typically a highly polished stainless steel plate. Any damage or imperfection on this surface can compromise the system's performance.

Installation Precision is Non-Negotiable

Proper alignment and support during installation are paramount. Methods like bolting, welding, or mortar embedment must be executed carefully to protect the PTFE surface and ensure the bearing is perfectly level and secure.

Making the Right Choice for Your Goal

Selecting a bearing system requires matching the component's strengths to the project's primary engineering challenge.

- If your primary focus is managing thermal expansion in long spans: PTFE's constant low friction ensures predictable, stress-free movement for bridges and large buildings.

- If your primary focus is minimizing lifetime operational costs: The maintenance-free nature and exceptional durability of PTFE eliminate all future servicing expenses.

- If your primary focus is accommodating seismic or unpredictable loads: PTFE's ability to prevent stick-slip provides reliable performance and structural isolation under dynamic forces.

Ultimately, choosing PTFE slide bearings is a decision for long-term structural integrity and operational predictability.

Summary Table:

| Key Advantage | Benefit in Construction |

|---|---|

| Low Coefficient of Friction | Prevents stick-slip, ensures smooth movement under load |

| High Load Capacity | Supports immense structural weights with reliability |

| Maintenance-Free Operation | Eliminates lifetime servicing costs and inspections |

| Chemical & Environmental Resistance | Withstands weathering, moisture, and chemicals for decades |

| Seismic & Thermal Accommodation | Manages expansion, contraction, and dynamic loads safely |

Optimize your construction project with precision-engineered PTFE components from KINTEK.

Our PTFE slide bearings are manufactured to exacting standards for the semiconductor, medical, laboratory, and industrial sectors, ensuring reliable performance in the most demanding environments. Whether you need a custom prototype or a high-volume order, our expertise in PTFE fabrication guarantees a solution tailored to your structural movement challenges.

Contact KINTEK today to discuss how our PTFE bearings can enhance your project's longevity and reduce lifetime costs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs