In the oil and gas industry, Teflon (PTFE) is primarily used for three critical functions. It serves as a superior sealing material for pipes, valves, and gaskets; as a low-friction, anti-wear coating on downhole tools; and as a protective, corrosion-resistant film for sensitive electronic components. These applications are essential for maintaining operational integrity in extremely harsh environments.

Teflon isn't just another material; it's a solution to the oil and gas industry's most hostile conditions. Its unique combination of extreme chemical inertness, high-temperature tolerance, and low-friction properties makes it indispensable for ensuring equipment reliability and preventing costly failures.

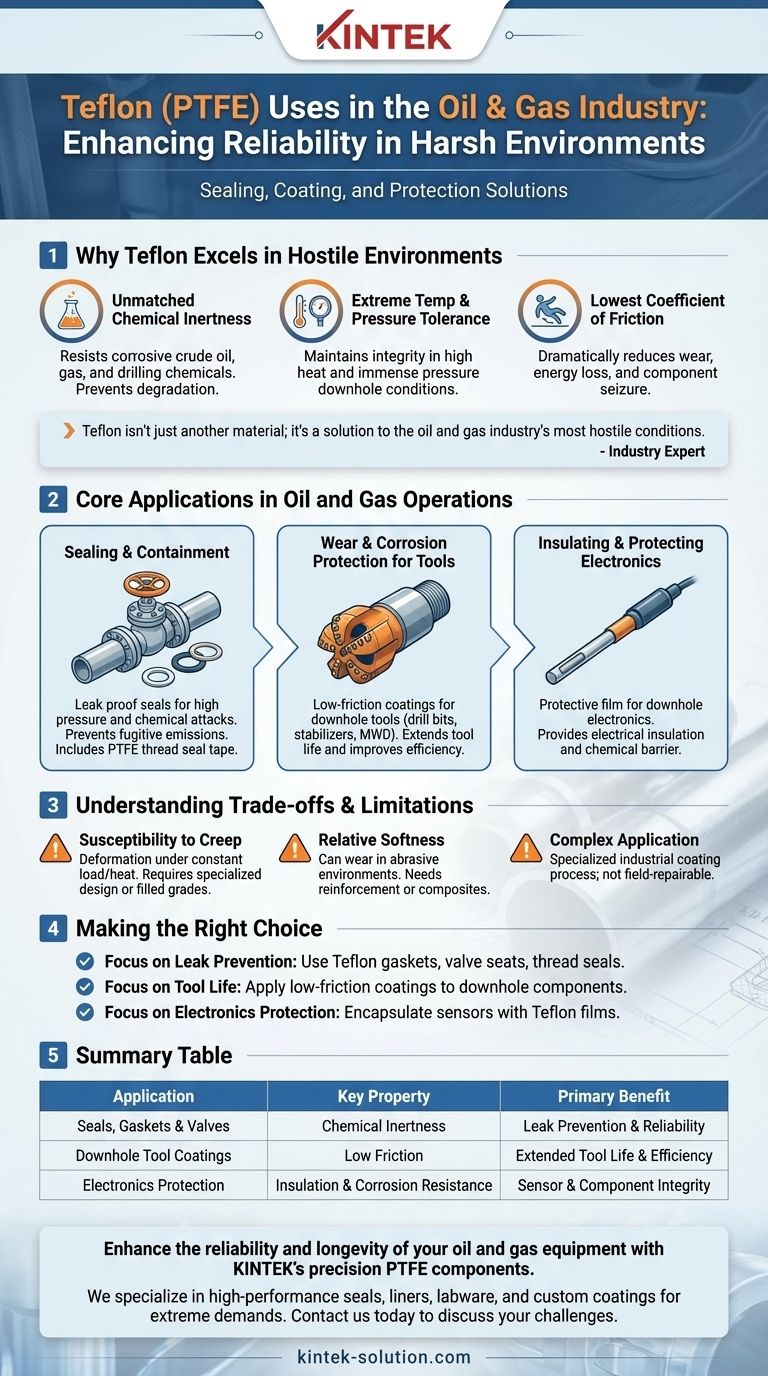

Why Teflon Excels in Hostile Environments

The value of Teflon, or Polytetrafluoroethylene (PTFE), in the oil and gas sector stems from a unique set of properties that directly counteract the industry's primary operational challenges.

Unmatched Chemical Inertness

The fluids encountered in exploration and production—from crude oil and natural gas to aggressive drilling chemicals—are highly corrosive. Teflon is almost completely inert, meaning it will not degrade or react when exposed to these substances, ensuring the longevity of the components it protects.

Extreme Temperature and Pressure Tolerance

Downhole environments are characterized by extreme heat and immense pressure. Teflon maintains its structural integrity and performance characteristics across a wide temperature range, preventing seals from failing and coatings from breaking down under these punishing conditions.

The Lowest Coefficient of Friction

Teflon possesses one of the lowest coefficients of friction of any known solid. This "slipperiness" is critical for applications where moving parts are under heavy load, as it dramatically reduces wear, energy loss, and the risk of components seizing.

Core Applications in Oil and Gas Operations

These fundamental properties translate into specific, high-value applications that improve safety, efficiency, and equipment lifespan.

Sealing and Containment

Perhaps its most common use, Teflon is a premier material for seals, gaskets, and valve seats. It creates a durable, leak-proof seal that can withstand high pressure and chemical attack, preventing fugitive emissions and loss of containment. PTFE thread seal tape is a ubiquitous component in nearly all pipe connections.

Wear and Corrosion Protection for Tools

Downhole tools, such as drill bits, stabilizers, and measurement-while-drilling (MWD) components, are subject to intense friction and wear. Applying a Teflon-based coating reduces this friction, which extends the life of the tool, improves drilling efficiency, and lowers the risk of costly equipment failure.

Insulating and Protecting Electronics

Modern drilling operations rely on sophisticated downhole electronics and sensors. Teflon is used as a protective coating or film for these sensitive components. It provides excellent electrical insulation and creates an impenetrable barrier against corrosive fluids, ensuring accurate data collection and tool function.

Understanding the Trade-offs and Limitations

While highly effective, Teflon is not a universal solution. An objective assessment requires acknowledging its limitations in certain contexts.

Susceptibility to Creep

Under a constant, heavy load—especially at elevated temperatures—PTFE can be susceptible to "creep," or slow deformation over time. In high-pressure sealing applications, this must be accounted for in the engineering design, often by using filled grades of Teflon or specific gasket designs.

Relative Softness and Abrasion Resistance

While Teflon has extremely low friction, it is a relatively soft material. In environments with high concentrations of abrasive particles, such as sand-laden drilling fluids, a pure PTFE coating can wear away. This is often mitigated by reinforcing the Teflon with other materials to create a more robust composite.

Complex Application Processes

Applying industrial-grade Teflon coatings is a specialized process requiring precise surface preparation and curing. It is not a field-repairable solution, meaning components must be coated in a controlled industrial setting.

Making the Right Choice for Your Goal

To apply this material effectively, your decision should be driven by the primary engineering problem you are trying to solve.

- If your primary focus is reliability and leak prevention: Use Teflon (PTFE) for gaskets, valve seats, and thread seals to reliably contain corrosive fluids and high pressures.

- If your primary focus is extending tool life: Apply specialized Teflon-based coatings to downhole components to significantly reduce friction and mitigate wear.

- If your primary focus is protecting sensitive equipment: Encapsulate downhole electronics and sensors with Teflon films for superior chemical and electrical insulation.

Ultimately, leveraging Teflon's unique properties is a strategic decision to enhance safety, reduce downtime, and ensure operational integrity in one of the world's most demanding industries.

Summary Table:

| Application | Key Property | Primary Benefit |

|---|---|---|

| Seals, Gaskets & Valves | Chemical Inertness | Leak Prevention & Reliability |

| Downhole Tool Coatings | Low Friction | Extended Tool Life & Efficiency |

| Electronics Protection | Insulation & Corrosion Resistance | Sensor & Component Integrity |

Enhance the reliability and longevity of your oil and gas equipment with KINTEK's precision PTFE components.

We specialize in manufacturing high-performance Teflon seals, liners, labware, and custom coatings specifically engineered for the extreme demands of the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our custom fabrication ensures your components meet the highest standards for chemical resistance, temperature tolerance, and low friction.

Contact us today to discuss how our PTFE solutions can solve your most challenging containment, wear, and protection problems. Get in touch with our experts

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials